Glass-ceramic bond for superhard material grinding wheel and preparation method thereof, superhard material grinding wheel and preparation method thereof, composite grinding wheel

A technology of glass-ceramic and superhard material, applied in the field of abrasives, can solve the problems of lengthening production cycle, wasting energy, increasing production cost, etc., and achieving the effect of improving flexural strength, reducing production cost and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

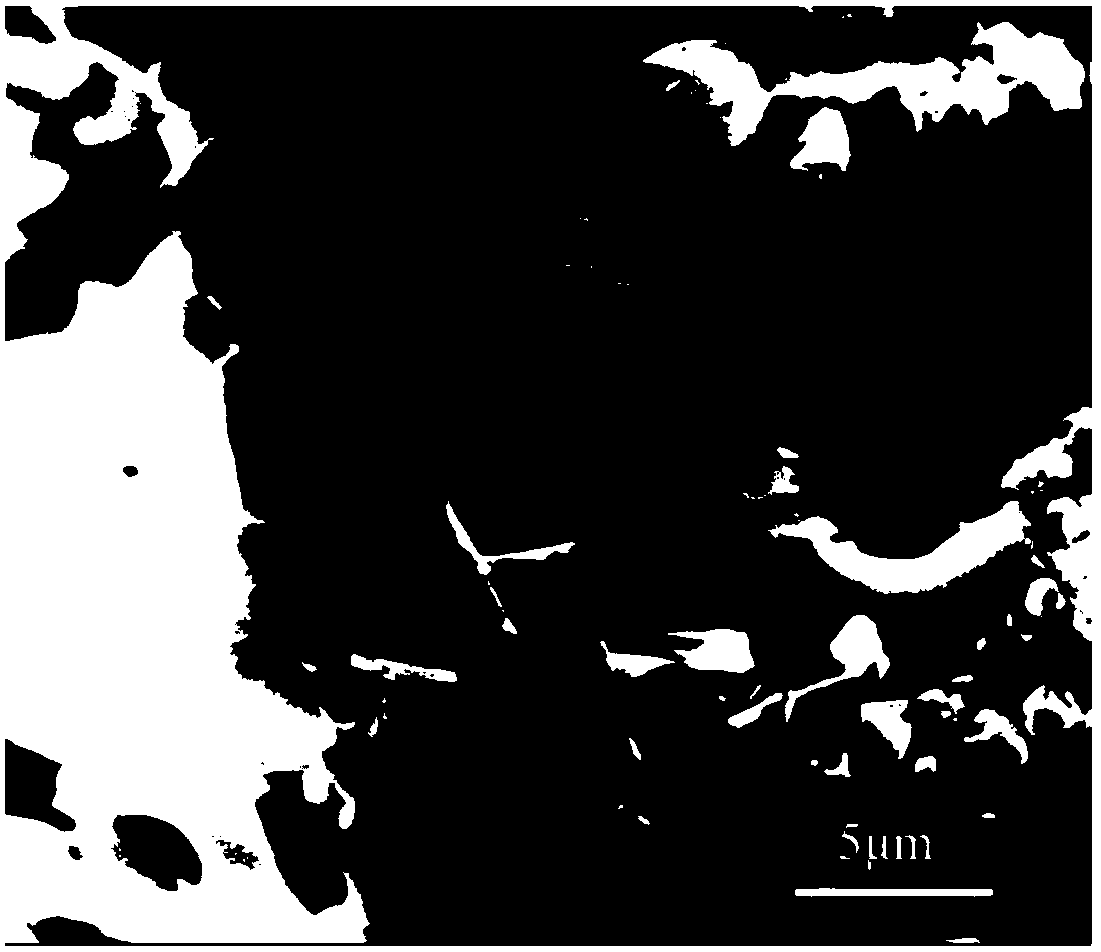

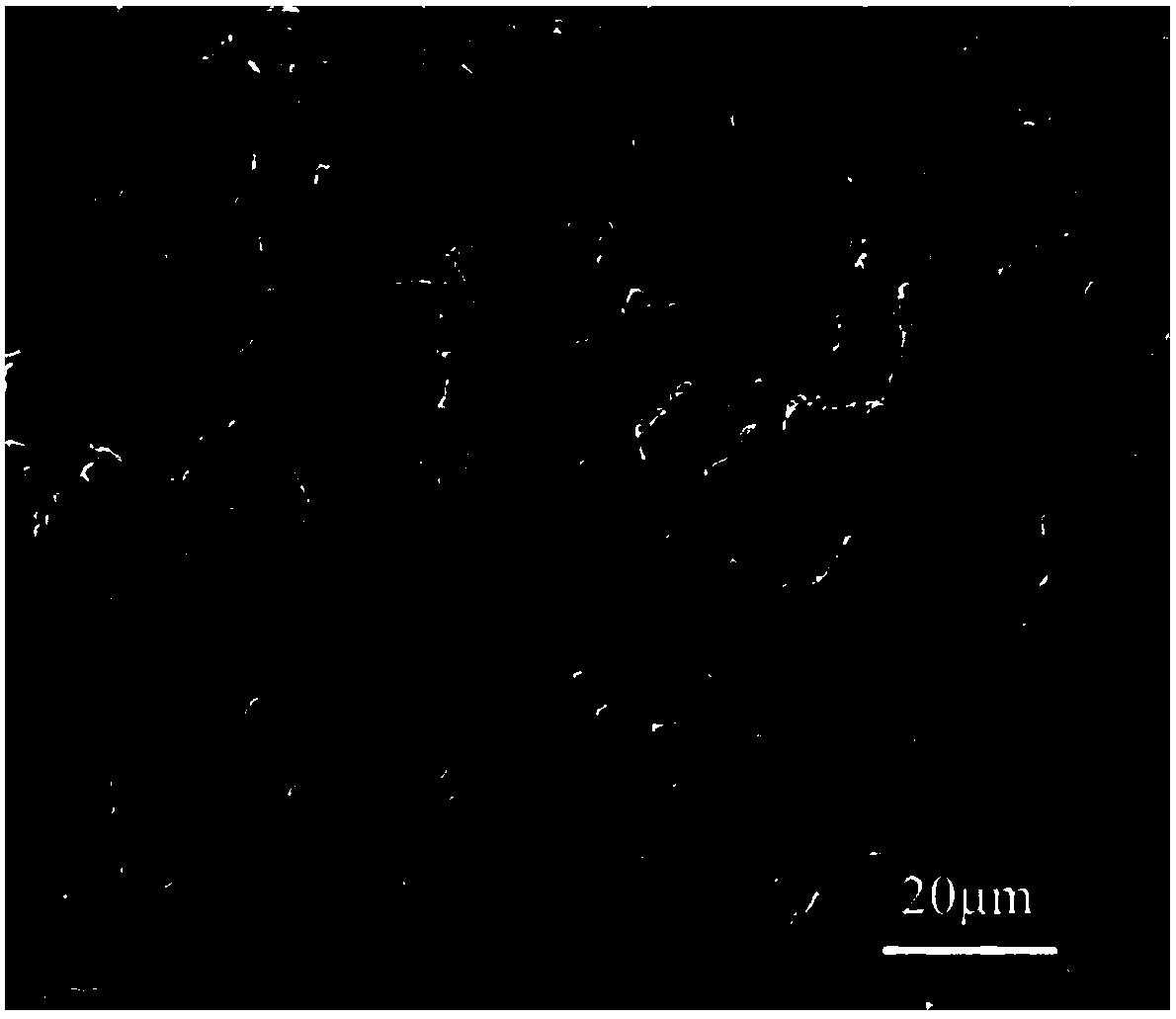

Image

Examples

Embodiment 1

[0051] The glass-ceramic bonding agent that is used for superhard material emery wheel of the present embodiment is made up of basic vitrified bonding agent and additive, and basic vitrified bonding agent is to be made by the raw material of following mass percent: 61% SiO 2 , 5%Al 2 o 3 , 10% B 2 o 3 , 3% CaO, 3% K 2 O, 11%Na 2 O, 4% Li 2 O, 3% BaO; additive is CaF 2 , the mass is 7.5% of the mass of the basic vitrified bond.

[0052] The preparation method of the glass-ceramic bonding agent that is used for superhard material grinding wheel of the present embodiment, comprises the following steps:

[0053] 1) According to the SiO in the basic vitrified bond 2 、Al 2 o 3 , B 2 o 3 , CaO, K 2 O, Na 2 O. Li 2 O, the mass percentage of BaO, calculate the quality of various raw materials required, accurately weigh various raw materials and use a ball mill to fully ball mill and mix them to make their components uniform, and pass through a 200-mesh sieve to obtain th...

Embodiment 2

[0065] The glass-ceramic bonding agent that is used for superhard material emery wheel of the present embodiment is made up of basic vitrified bonding agent and additive, and basic vitrified bonding agent is to be made by the raw material of following mass percent: 61% SiO 2 , 5% Al 2 o 3 , 10% B 2 o 3 , 3% CaO, 3% K 2 O, 11%Na 2 O, 4% Li 2 O, 3% BaO; additive is CaF 2 , the mass is 10% of the mass of the basic vitrified bond.

[0066] The preparation method of the glass-ceramic bonding agent that is used for superhard material grinding wheel of the present embodiment, comprises the following steps:

[0067] 1) According to the SiO in the basic vitrified bond 2 、Al 2 o 3 , B 2 o 3 , CaO, K 2 O, Na 2 O. Li 2 O, the mass percentage of BaO, calculate the quality of various raw materials required, accurately weigh various raw materials and use a ball mill to fully ball mill and mix them to make their components uniform, and pass through a 200-mesh sieve to obtain th...

Embodiment 3

[0079] The glass-ceramic bonding agent that is used for superhard material emery wheel of the present embodiment is made up of basic vitrified bonding agent and additive, and basic vitrified bonding agent is to be made by the raw material of following mass percent: 61% SiO 2 , 5%Al 2 o 3 , 10% B 2 o 3 , 3% CaO, 3% K 2 O, 11%Na 2 O, 4% Li 2 O, 3% BaO; additive is CaF 2 , the mass is 2.5% of the mass of the basic vitrified bond.

[0080] The preparation method of the glass-ceramic bonding agent that is used for superhard material grinding wheel of the present embodiment, comprises the following steps:

[0081] 1) According to the SiO in the basic vitrified bond 2 、Al 2 o 3 , B 2 o 3 , CaO, K 2 O, Na 2 O. Li 2 O, the mass percentage of BaO, calculate the quality of various raw materials required, accurately weigh various raw materials and use a ball mill to fully ball mill and mix them to make their components uniform, and pass through a 200-mesh sieve to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com