Two-way cutting device for automobile lining molding

A cutting device and lining technology, used in metal processing, removing smoke and dust, cleaning methods and utensils, etc., can solve the problems of product fineness not meeting requirements, increased workload, low work efficiency, etc., saving manpower and labor. The effect of strength, no blockage of waste water discharge, and rapid waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

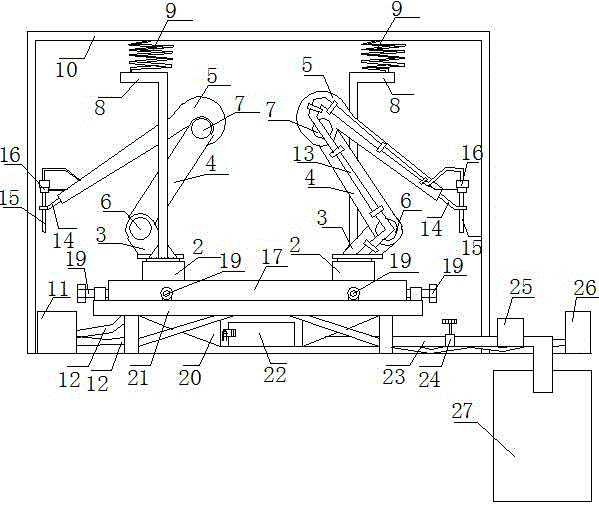

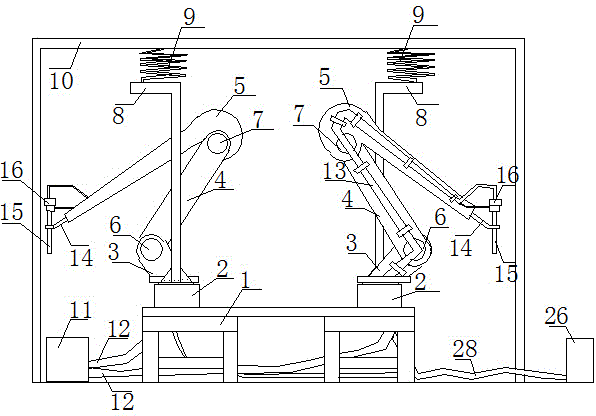

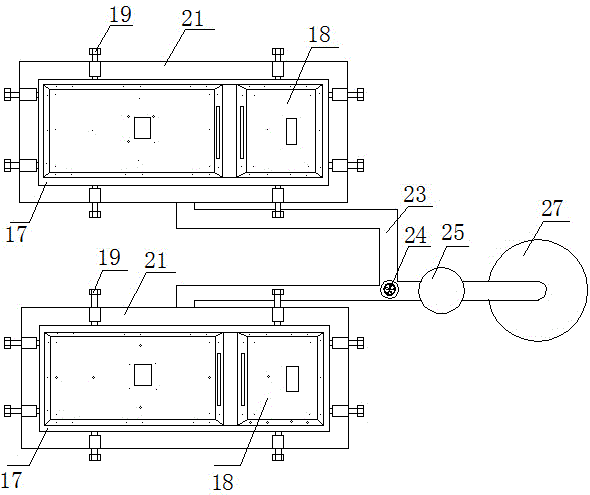

[0014] Such as figure 1 , figure 2 and image 3 As shown, a two-way cutting device for automobile inner lining molding of the present invention includes a two-way water cutting mechanism, a workbench, a waste processing mechanism and an electric control system. The two-way water cutting mechanism includes a machine base 1, a rotating motor 2, a lower arm 3, a middle Arm 4, upper arm 5, articulation motor one 6, articulation motor two 7, return lever 8, return spring 9, cross bar 10, water tank 11, water pipe 12, water cutter fixed arm 14, water cutter 15 and high pressure pump 16, The machine base 1 fixes two rotating motors 2 in a symmetrical form, and the output shaft of each rotating motor 2 is connected to the lower end of the lower arm 3, and the upper end of the lower arm 3 is connected to the lower end of the middle arm 4 through a hinge mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com