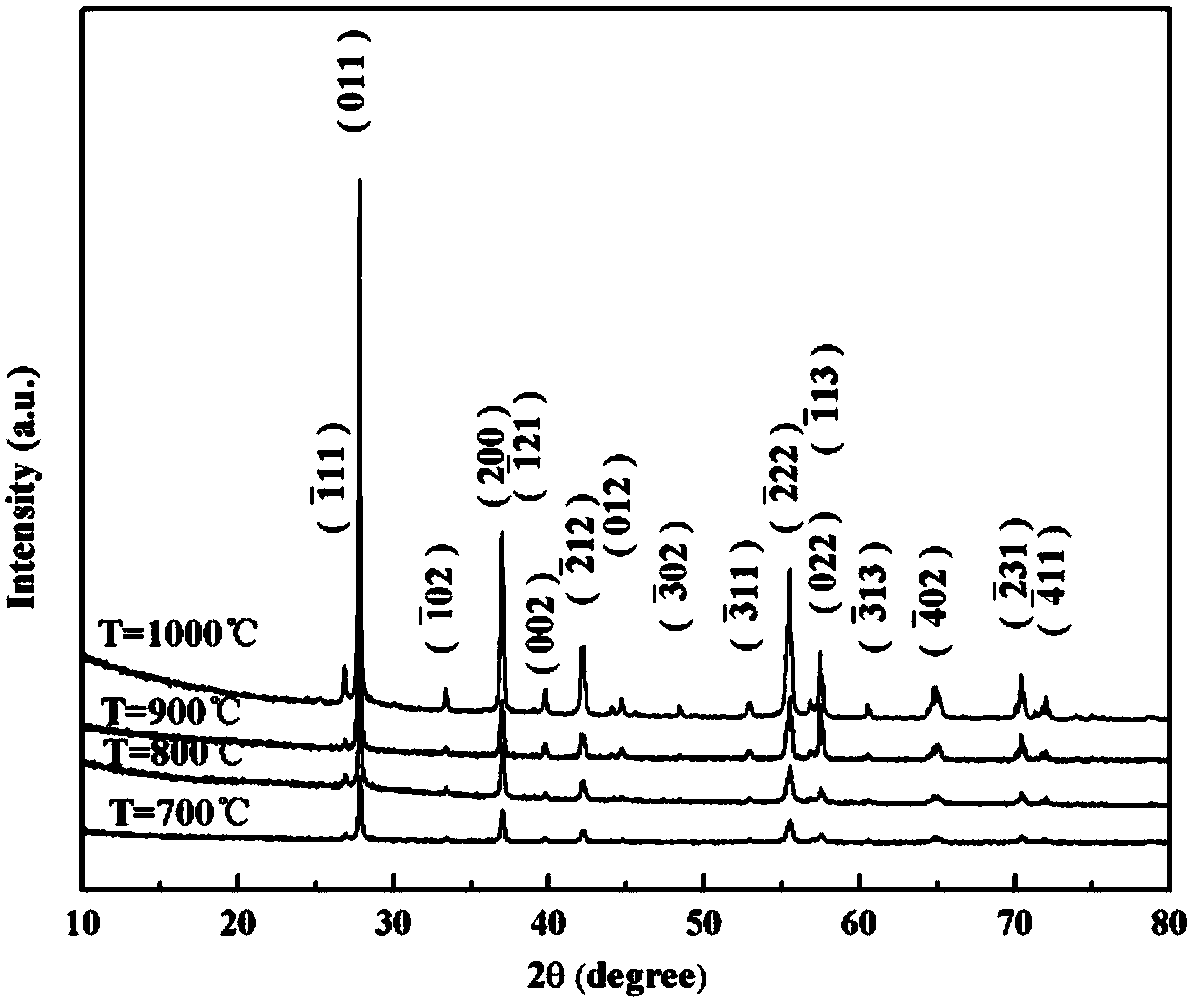

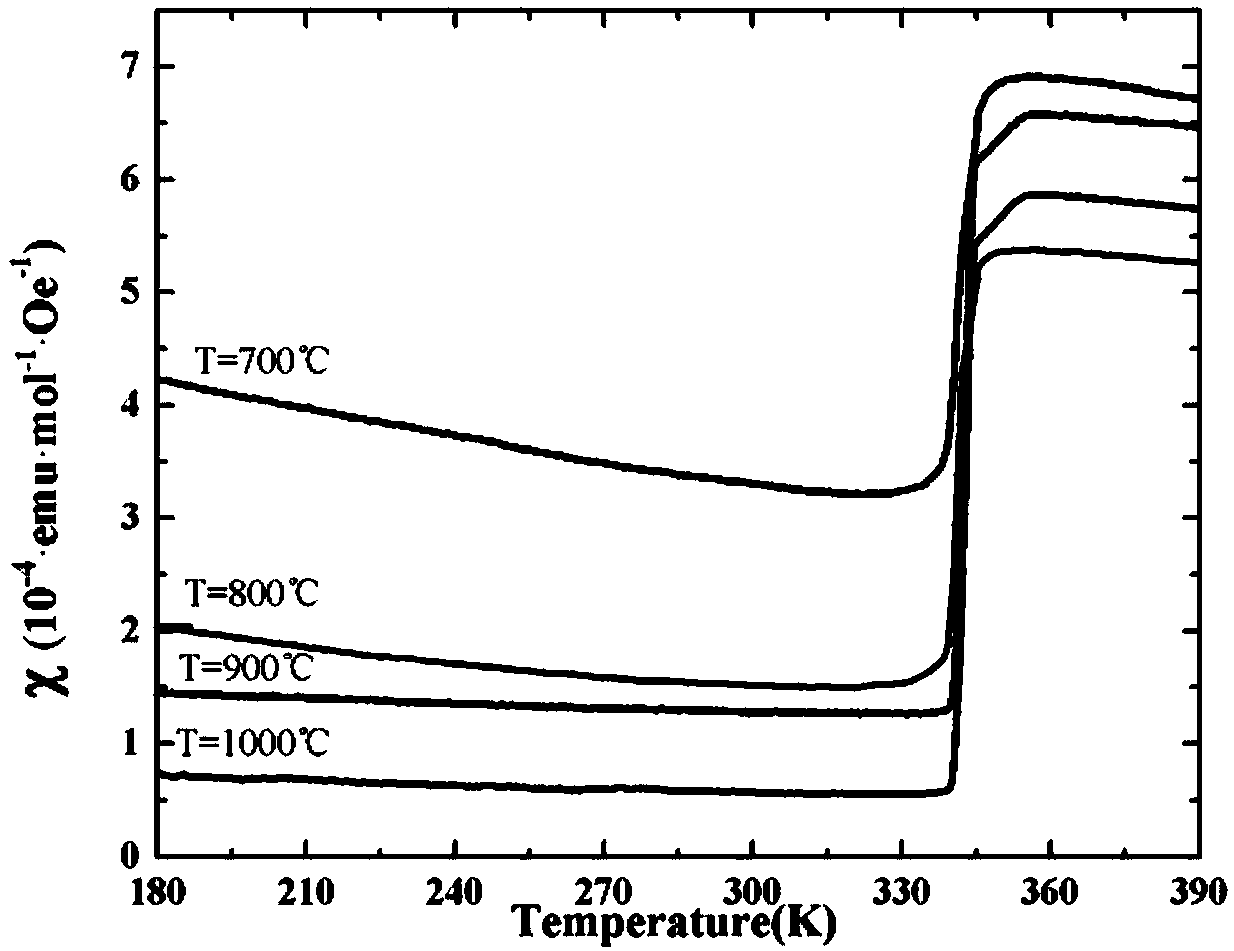

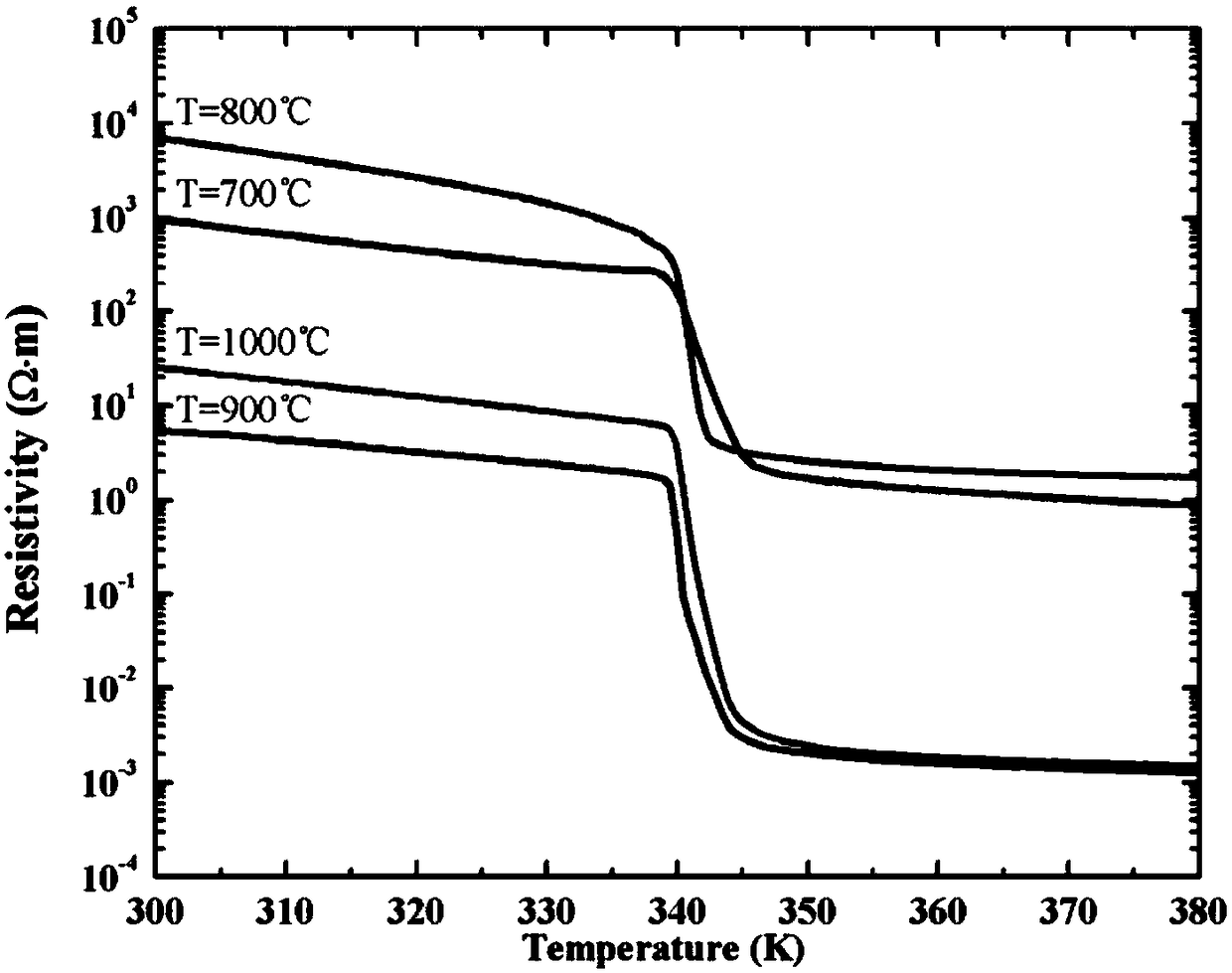

A Rapid Preparation Method of Monoclinic VO2 Metal-Insulator Phase Change Ceramic Material

A ceramic material, VO2 technology, applied in the field of rapid preparation of monoclinic VO2 metal-insulator phase change ceramics, can solve the problems of insufficient physical performance, cumbersome synthesis method, harsh raw material requirements, etc., to shorten the preparation time and reduce the cost of raw materials. , the effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Using Citric Acid-V 2 o 5 Preparation of Monoclinic VO by Hydrothermal Reaction 2 Powder:

[0027] (1) Measure 0.00375mol citric acid into a 50mL beaker, add 20mL deionized water, dissolve under magnetic stirring to form a transparent solution, then weigh 0.0025molV 2 o 5 Add the solid powder to the above citric acid solution, and magnetically stir together for about 30 minutes to form a uniform yellow solution. The concentration of citric acid-vanadium pentoxide in the mixed solution is 0.025±5% g / mL;

[0028] (2) Pour the above yellow solution into a 50mL stainless steel hydrothermal synthesis reaction kettle, and measure 10mL of deionized water several times to rinse the residual drug in step (1), and add it to the reaction kettle together, and the final reaction solution is about 50mL , then put the reactor into an oven, heat to 180°C, and continue the reaction for 5 hours;

[0029] (3) After the above reaction time is over, the solid-liquid separation of th...

Embodiment 2

[0036] 1. Using Citric Acid-V 2 o 5 Preparation of Monoclinic VO by Hydrothermal Reaction 2 Powder:

[0037] (1) Measure 0.00625mol citric acid into a 50mL beaker, add 20mL deionized water, dissolve under magnetic stirring to form a transparent solution, then weigh 0.0025molV 2 o 5Add the solid powder to the above citric acid solution, and magnetically stir together for about 30 minutes to form a uniform yellow solution. The concentration of citric acid-vanadium pentoxide in the mixed solution is 0.025±5% g / mL;

[0038] (2) Pour the above yellow solution into a 50mL stainless steel hydrothermal synthesis reaction kettle, and measure 10mL of deionized water several times to rinse the residual drug in step (1), and add it to the reaction kettle together, and the final reaction solution is about 50mL , and then put the reactor into an oven, heat it to 170°C, and continue the reaction for 10 hours;

[0039] (3) After the above reaction time is over, the solid-liquid separatio...

Embodiment 3

[0046] 1. Using Citric Acid-V 2 o 5 Preparation of Monoclinic VO by Hydrothermal Reaction 2 Powder:

[0047] (1) Measure 0.00525mol citric acid into a 50mL beaker, add 20mL deionized water, dissolve under magnetic stirring to form a transparent solution, then weigh 0.0025molV 2 o 5 Add the solid powder to the above citric acid solution, and magnetically stir together for about 30 minutes to form a uniform yellow solution. The concentration of citric acid-vanadium pentoxide in the mixed solution is 0.025±5% g / mL;

[0048] (2) Pour the above yellow solution into a 50mL stainless steel hydrothermal synthesis reaction kettle, and measure 10mL of deionized water several times to rinse the residual drug in step (1), and add it to the reaction kettle together, and the final reaction solution is about 50mL , then put the reactor into an oven, heat to 190°C, and continue the reaction for 8 hours;

[0049] (3) After the above reaction time is over, the solid-liquid separation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com