Preparation method of MnZn ferrite powder with galvanizing zinc slag and pickling waste liquid as raw materials

A technology for pickling waste liquid and ferrite, which is applied in the field of MnZn ferrite powder preparation, can solve the problems of long process and uneven doping, etc., and achieves the effects of low cost, stable product quality and reduction of production links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

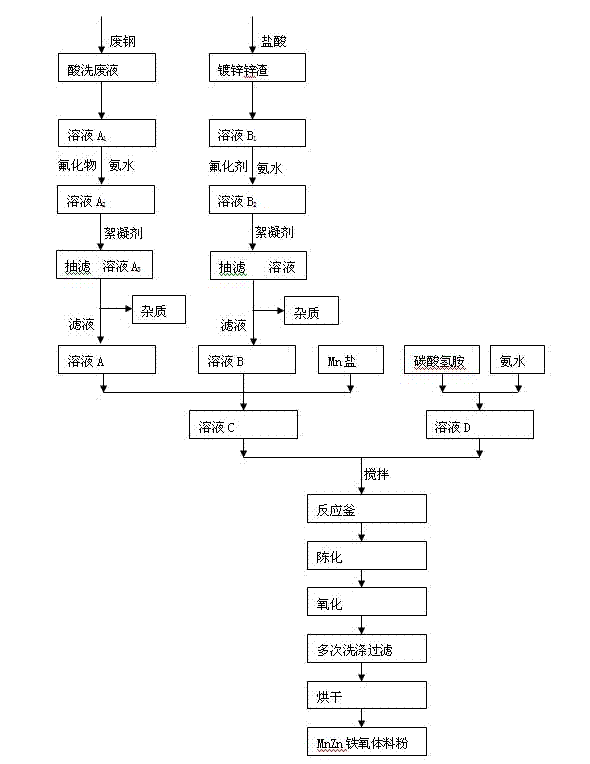

[0032] Example 1: figure 1 Shown, this galvanizing slag and pickling waste liquid are the concrete processing steps of the MnZn ferrite material powder preparation method of raw material:

[0033] 1. Purification of pickling waste liquid:

[0034] (1) Add 180g of steel scrap to each liter of pickling waste solution to neutralize the free acid in the pickling waste and reduce Fe 3+ for Fe 2+ ; Obtain solution A after filtration 1 ;

[0035] (2) Control Solution A 1 temperature at 40°C, to solution A 1 Aqueous ammonia was added to adjust the pH value of the system to 5.5 to obtain solution A 2 ;

[0036] (3) To each liter of solution A 2 Add 1.7ml of 1wt% ammonium fluoride solution to the solution and react for 1.5h to obtain solution A 3 ;

[0037] (4) To the above-mentioned solution A per liter 3 Add 7.6mg of 8173 flocculant in the solution; the precipitate is filtered out by suction filtration, and the obtained filtrate is solution A.

[0038] 2. Leaching and puri...

Embodiment 2

[0048] Example 2: figure 1 Shown, this galvanizing slag and pickling waste liquid are the concrete processing steps of the MnZn ferrite material powder preparation method of raw material:

[0049] 1. Purification of pickling waste liquid:

[0050] (1) Add 140g of steel scrap to each liter of pickling waste solution to neutralize the free acid in the pickling waste and reduce Fe 3+ for Fe 2+ ; Obtain solution A after filtration 1 ;

[0051] (2) Control Solution A 1 temperature at 50°C, to solution A 1 Add ammonia water to adjust the pH value of the system to 5 to obtain solution A 2 ;

[0052] (3) To each liter of solution A 2 Add 2ml of 1wt% ammonium fluoride solution, react for 2h, obtain solution A 3 ;

[0053] (4) To the above-mentioned solution A per liter 3 Add 8 mg of 8173 flocculant in the solution; filter the precipitate by suction filtration, and the obtained filtrate is solution A.

[0054] 2. Leaching and purification of galvanized slag:

[0055] (1) Pu...

Embodiment 3

[0064] Example 3: figure 1 Shown, this galvanizing slag and pickling waste liquid are the concrete processing steps of the MnZn ferrite material powder preparation method of raw material:

[0065] 1. Purification of pickling waste liquid:

[0066] (1) Add 200g of steel scrap to each liter of pickling waste solution to neutralize the free acid in the pickling waste and reduce Fe 3+ for Fe 2+ ; Obtain solution A after filtration 1 ;

[0067] (2) Control Solution A 1 temperature at 30°C, to solution A 1 Add ammonia water to adjust the pH value of the system to 6 to obtain solution A 2 ;

[0068] (3) To each liter of solution A 2 Add 1ml of 1wt% sodium fluoride solution to the solution and react for 1h to obtain solution A 3 ;

[0069] (4) To the above-mentioned solution A per liter 3 Add 6.8mg of polyacrylamide (flocculant) to the solution; remove the precipitate by suction filtration, and the obtained filtrate is solution A.

[0070] 2. Leaching and purification of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com