Nb5+ doped monoclinic phase VO2 metal-insulator transition ceramic and preparation method thereof

A VO2, monoclinic phase technology, applied in the field of phase change ceramic materials, can solve the problems of poor repeatability, complex procedures, and the inability to effectively control the doping ratio, and achieve rich physical property transformation, repeatable preparation process, and shorten the preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

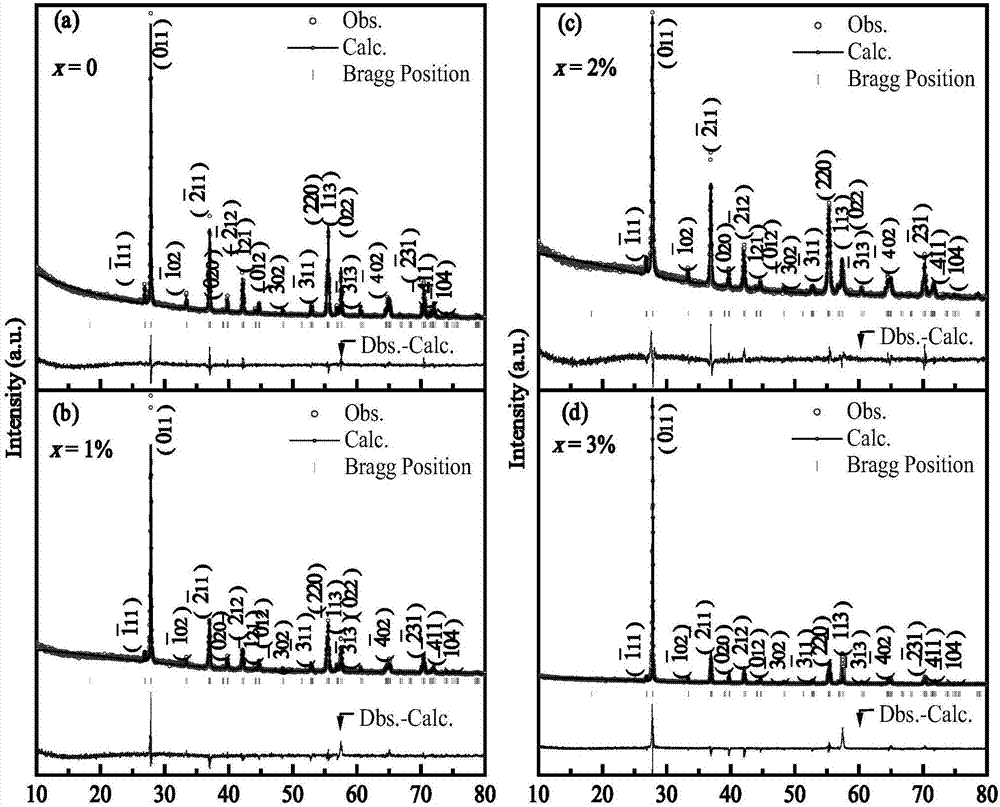

[0030] Nb proposed by the present invention 5+ doped monoclinic VO 2 A method for preparing a metal-insulator phase-change ceramic, comprising the following steps:

[0031] (1) at room temperature, at first, the citric acid that has weighed is put into beaker, adds deionized water, dissolves under magnetic stirring, forms transparent solution; Then weigh analytically pure vanadium pentoxide and put into beaker, Magnetic stirring together to form a homogeneous solution; wherein the molar ratio of vanadium pentoxide to citric acid is 1:1.5-2.5, and the concentration of citric acid-vanadium pentoxide in the mixed solution is 0.025±5% g / mL;

[0032] (2) Pour the uniformly stirred mixed solution into a closed high-temperature and high-pressure container, and then put the container into an oven and heat it at 170°C to 190°C to ensure the high-temperature and high-pressure hydrothermal reaction inside the container; the reaction time is 5-10 hours;

[0033] (3) After the reaction i...

Embodiment 1

[0039] 1. Using Citric Acid-V 2 o 5 Preparation of Monoclinic VO by Hydrothermal Reaction 2 Powder raw material:

[0040] (1) Measure 0.00375mol of citric acid into a 50mL beaker, add 20mL of deionized water, dissolve under magnetic stirring to form a transparent solution, and then weigh 0.0025molV 2 o 5 Add the solid powder to the above citric acid solution, and magnetically stir together for about 30 minutes to form a uniform yellow solution. The concentration of citric acid-vanadium pentoxide in the mixed solution is 0.025±5% g / mL;

[0041] (2) Pour the above yellow solution into a 50mL stainless steel hydrothermal synthesis reaction kettle, and measure 10mL of deionized water several times to rinse the residual drug in step (1), and add it to the reaction kettle together, and the final reaction solution is about 50mL , then put the reactor into an oven, heat to 180°C, and continue the reaction for 5 hours;

[0042] (3) After the above reaction time is over, the solid-...

Embodiment 2

[0050] 1. Using Citric Acid-V 2 o 5 Preparation of Monoclinic VO by Hydrothermal Reaction 2 Powder raw material:

[0051] Prepared by the method in Example 1.

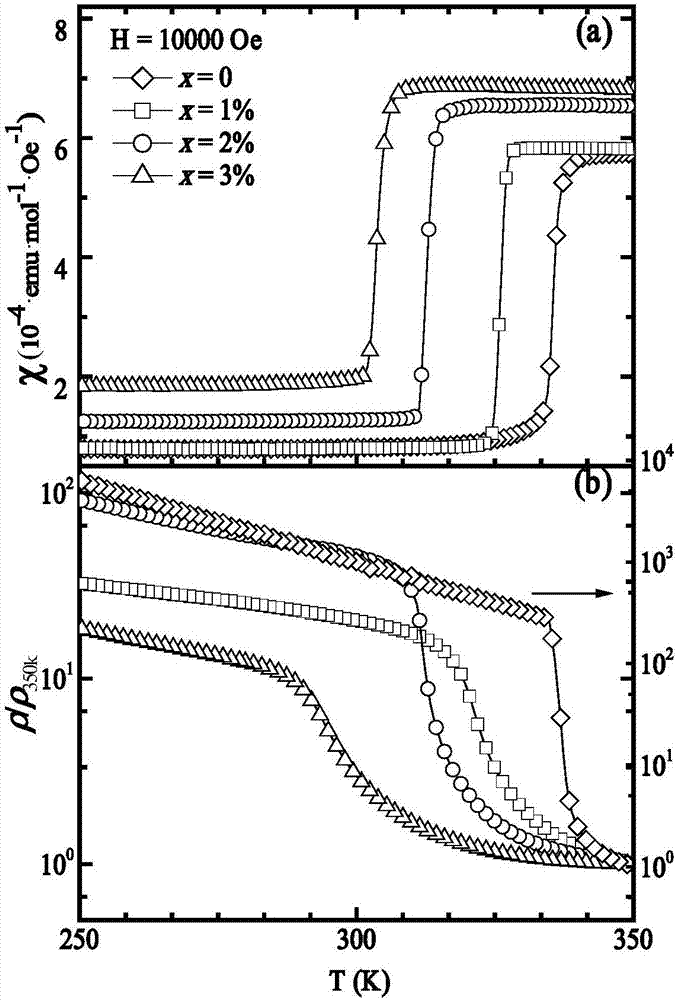

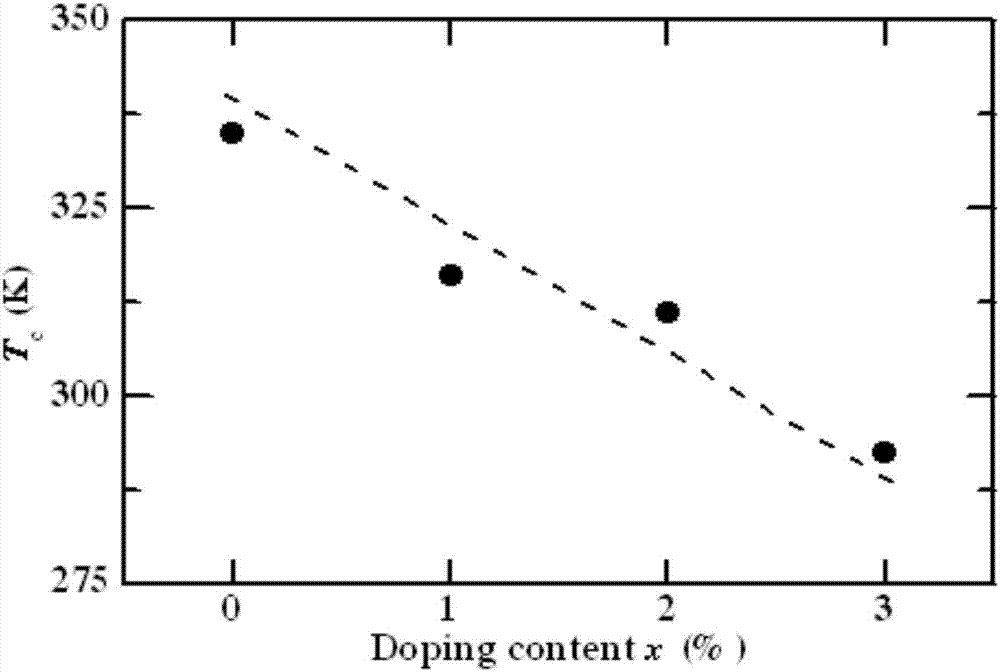

[0052] 2. Preparation of Nb by high temperature sintering 5+ Doping 1% VO 2 The metal-insulator phase change ceramic bulk, that is, the atomic number ratio of vanadium and niobium in the phase change ceramic is 99%:1%, including the following process:

[0053] (1) Calculate and weigh the monoclinic phase VO obtained by the above operation according to the atomic number ratio of vanadium and niobium 99%:1%. 2 Powder 0.5747g, and measured 0.0050g Nb 2 o 5 The powders are mixed, fully ground for 2 hours, and then pressed into tablets;

[0054] (2) Doping Nb obtained by the above operation 2 o 5 Flake VO 2 Put it into a clean quartz ark, and then put it into a tube furnace; wash the gas environment in the tube furnace quartz tube with 400 sccm of ordinary pure argon for 10 minutes, and pump the tube furnace with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com