Sodium ion battery negative electrode material

A technology for sodium ion batteries and negative electrode materials, applied in the field of materials, can solve the problems of unstable structure, low specific capacity and rate performance, and poor sodium storage performance of nanoparticles, and achieve improved ionic and electronic conductivity and excellent rate. performance, the effect of improving sodium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

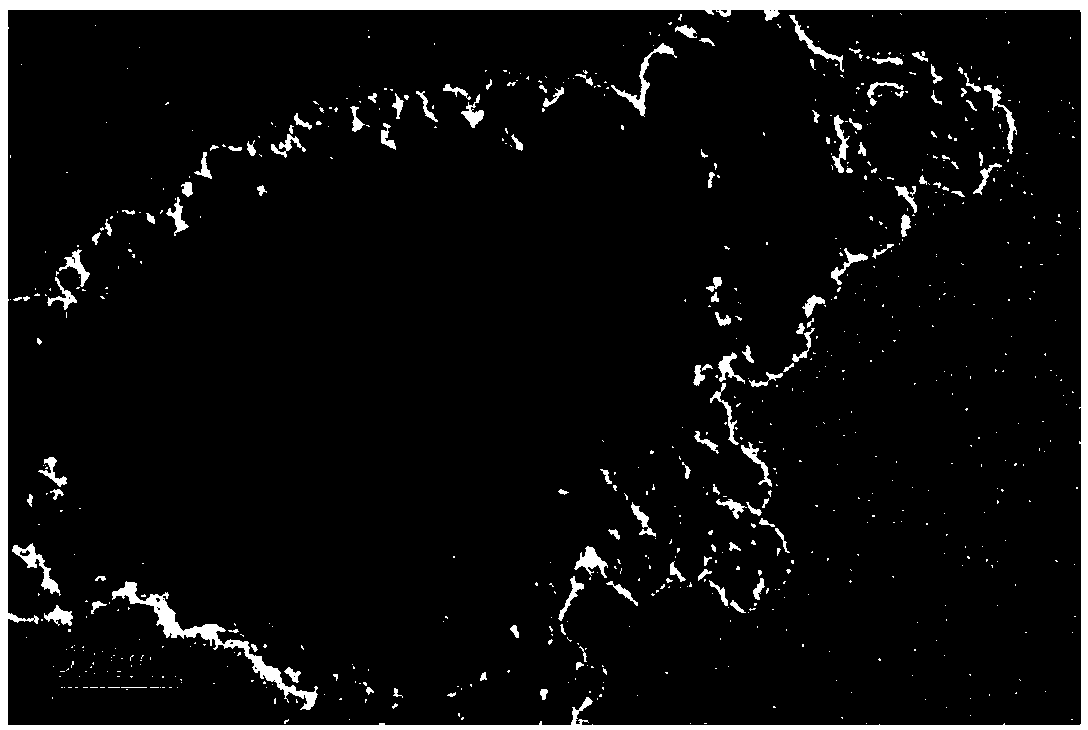

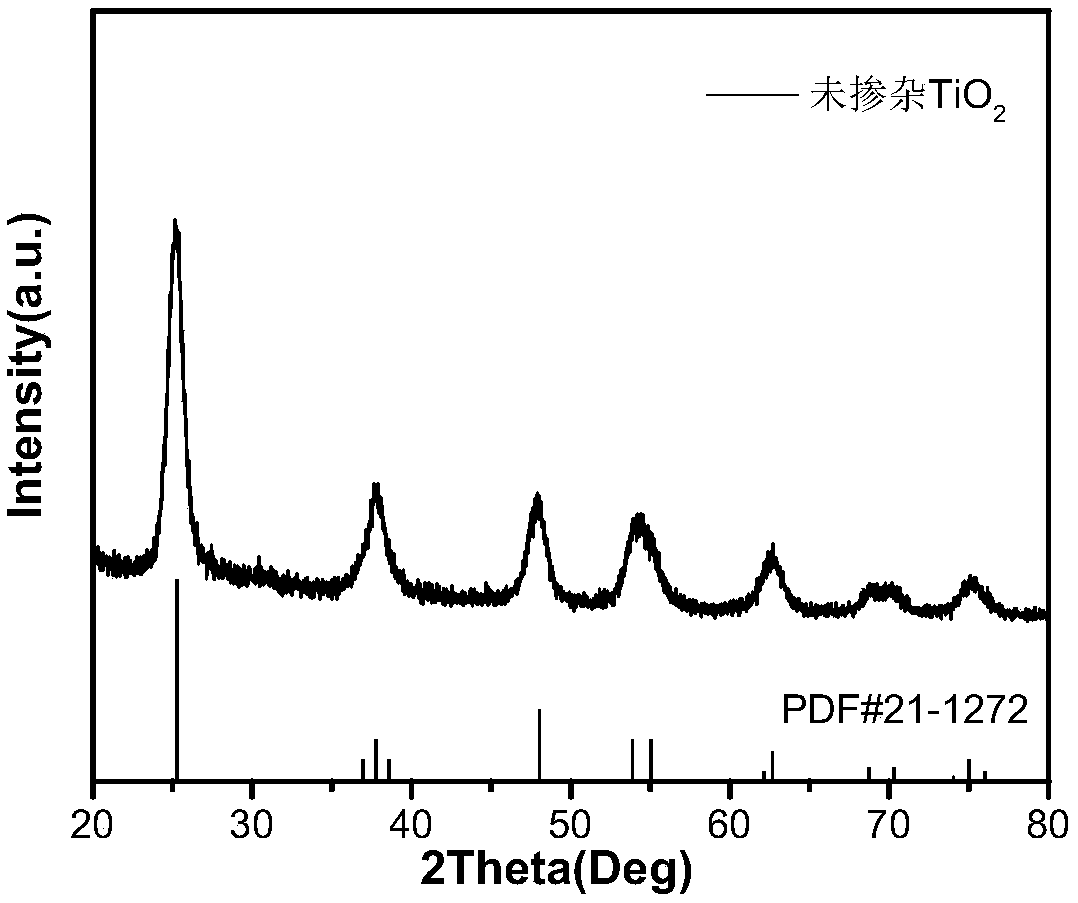

[0031] Example 1 is a comparative example, using a one-step solvothermal method, mixing and stirring a certain proportion of deionized water and an organic titanium source (butyl titanate), and synthesizing undoped TiO by solvothermal method 2 nanoparticles. Specific steps are as follows:

[0032] Step 1. Add 25ml of butyl titanate and 6ml of deionized water to the inner lining of the reaction kettle in sequence, and keep stirring evenly with a magnetic stirrer;

[0033] Step 2. Put the reaction kettle into a vacuum blast drying oven, set the reaction temperature of the heat-dissolving agent to 180°C and the time to 24h, and start the reaction;

[0034] Step 3, after the reaction finishes, the reaction system is cooled to room temperature with the furnace;

[0035] Step 4. Remove the supernatant in the inner lining of the reactor, wash and centrifuge the bottom product of the reactor with deionized water and ethanol for 6 times, the centrifugal speed is 8000-9000r / min, the c...

Embodiment 2

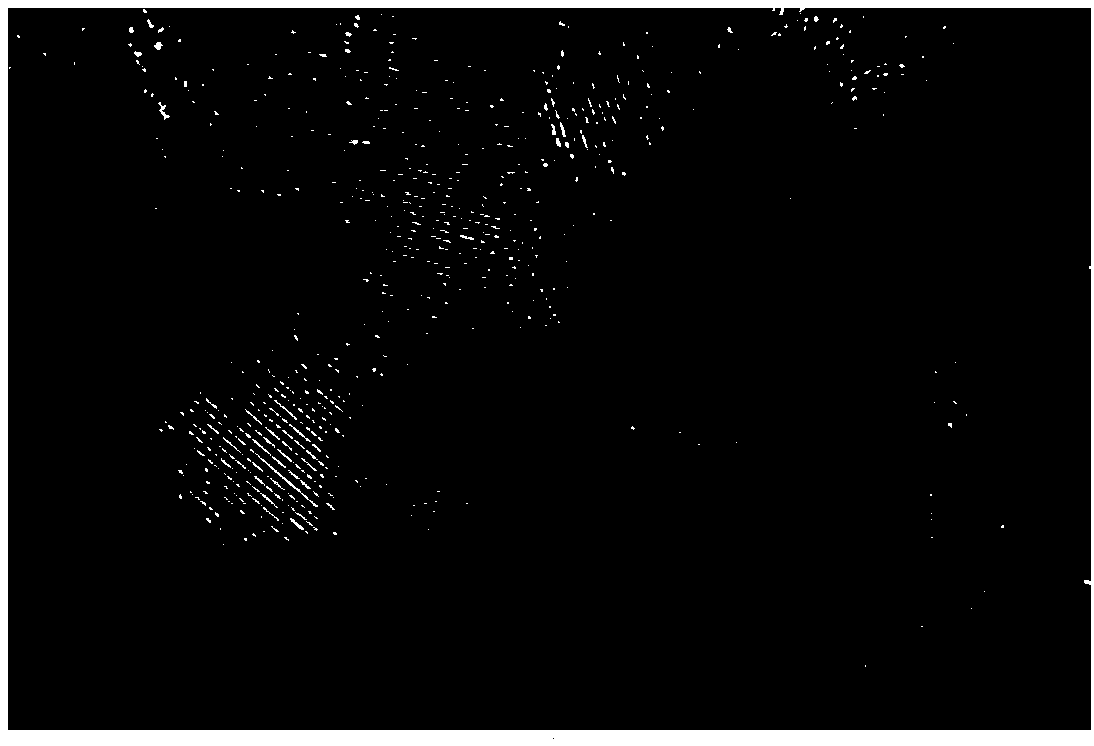

[0038] Example 2 is a comparative example, using a one-step solvothermal method, mixing and stirring a certain proportion of deionized water, organic titanium source (butyl titanate) and fluorine source (hydrofluoric acid), and synthesizing ultra-small fluorine through solvothermal method doped TiO 2 nanoparticles. Specific steps are as follows:

[0039] Step 1. Add 25ml of butyl titanate, 5ml of deionized water and 1ml of hydrofluoric acid with a mass percentage of 40% to the inner lining of the reaction kettle in sequence, and keep uniform stirring with a magnetic stirrer;

[0040] Step 2. Put the reaction kettle into a vacuum blast drying oven, set the reaction temperature of the heat-dissolving agent to 180°C and the time to 24h, and start the reaction;

[0041] Step 3, after the reaction finishes, the reaction system is cooled to room temperature with the furnace;

[0042] Step 4. Remove the supernatant in the inner lining of the reactor, wash and centrifuge the bottom...

Embodiment 3

[0045] The sodium ion battery negative electrode of the present invention adopts fluorine-doped TiO 2 Nanoparticles in which fluorine doped TiO 2 The preparation method of nanoparticles is as follows. Using a one-step solvothermal method, a certain proportion of deionized water, organic titanium source (butyl titanate) and fluorine source (hydrofluoric acid) are mixed and stirred evenly, and ultra-small fluorine is synthesized by solvothermal method. doped TiO 2 Nanoparticles, by adjusting the ratio between the organic titanium source and the fluorine source, a single-phase structure, good crystallinity, uniform size, and easy preparation of ultra-small fluorine-doped TiO 2 Nanoparticles, the specific steps are as follows:

[0046] Step 1. Add 25ml of butyl titanate, 3ml of deionized water and 3ml of hydrofluoric acid with a mass percentage of 40% to the inner lining of the reaction kettle in sequence, and keep uniform stirring with a magnetic stirrer;

[0047] Step 2. Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com