Method for lepidolite defluorination and valuable metal leaching

A technology of valuable metals and lepidolite, applied in the direction of improving process efficiency, etc., can solve the problems of low leaching rate of valuable metals, poor environment of roasting workshop, and large corrosion of equipment, so as to improve defluorination rate and leaching of valuable metals efficiency, reduce equipment investment, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

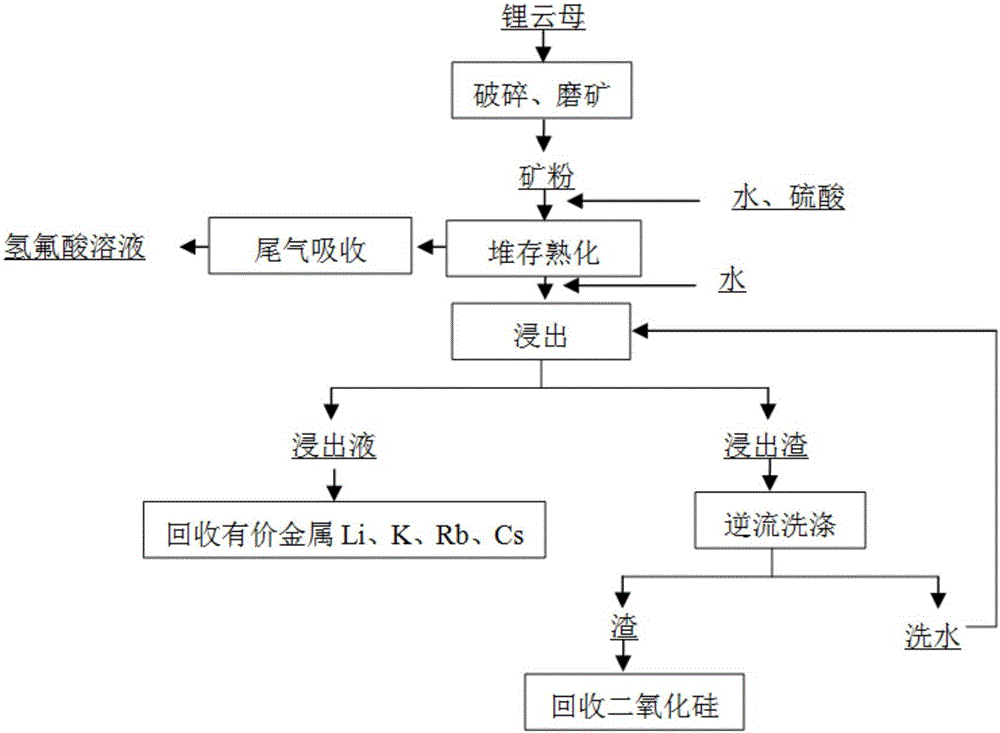

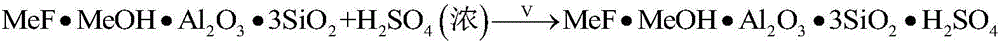

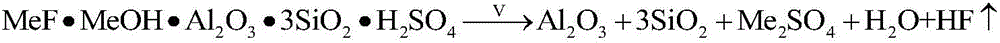

Method used

Image

Examples

Embodiment 1

[0039] The main composition of lepidolite is Li 2 O 3.95%, Rb 2 O 1.11%, Cs 2 O 0.288%, K 2 O 7.02%, Fe0.18%, SiO 2 52.73%, Al 2 o 3 25.26%, F 4.45%.

[0040] Grind lepidolite until the particle size is less than 0.074mm and account for 70%. Take 100kg of fine ore, add 80kg of concentrated sulfuric acid with a mass concentration of 93%, mix well, then add 0.08kg of water, mix well, and the mixing time is 3min. Storage aging defluorination, storage time is 30h. Obtain 176kg (dry basis) of mature ore, the mature ore contains F 0.12%, and the defluorination rate is 95.25%.

[0041] Add 440kg of water to the mature ore, stir and leaching in the leaching tank for 1 hour, the leaching temperature is 100°C, filter the pulp, and wash the leaching slag countercurrently for 4 times to obtain 67.6kg (dry basis) of leaching slag. The leaching slag contains Li 2 O 0.49%, Rb 2 O 0.15%, Cs 2 O0.041%, K 2 O 1.0%, Li 2 O, Rb 2 O, Cs 2 O, K 2 O leaching rates were 91.61%, 90.8...

Embodiment 2

[0043] The main composition of lepidolite is Li 2 O 2.35%, Rb 2 O 0.89%, Cs 2 O 0.120%, K 2 O 6.42%, Fe0.12%, SiO 2 53.21%, Al 2 o 3 24.12%, F 3.60%.

[0044] Grind lepidolite until the particle size is less than 0.074mm and account for 75%. Take 100kg of fine ore, add 90kg of concentrated sulfuric acid with a mass concentration of 93%, mix well, then add 0.09kg of water, mix well, and the mixing time is 4min. Storage aging defluorination, storage time is 25h. 187kg (dry basis) of mature ore was obtained, the mature ore contained F 0.09%, and the defluorination rate was 95.33%.

[0045] Add 280kg of water to the mature ore, stir and leaching in the leaching tank for 2.5h, the leaching temperature is 95°C, filter the pulp, wash the leaching slag countercurrently for 3 times, and obtain 65.30kg of leaching slag (dry basis). The leaching slag contains Li 2 O 0.32%, Rb 2 O 0.11%, Cs 2 O0.015%, K 2 O 0.80%, Li 2O, Rb 2 O, Cs 2 O, K 2 O leaching rates were 91.11%, ...

Embodiment 3

[0047] The main composition of lepidolite is Li 2 O 1.96%, Rb 2 O 0.74%, Cs 2 O 0.100%, K 2 O 5.35%, Fe0.16%, SiO 2 54.62%, Al 2 o 3 26.34%, F 3.40%.

[0048] Grind lepidolite until the particle size is less than 0.074mm, accounting for 80%. Take 100kg of fine ore, add 100kg of concentrated sulfuric acid with a mass concentration of 93%, mix well, then add 0.1kg of water, mix well, and the mixing time is 6min. Storage aging defluorination, storage time is 20h. Obtain 196kg (dry basis) of mature ore, the content of F in the mature ore is 0.08%, and the defluorination rate is 95.38%.

[0049] Add 196kg of water to the mature ore, stir and leaching in the leaching tank for 4 hours, the leaching temperature is 90°C, filter the pulp, and wash the leaching slag countercurrently twice to obtain 63.10kg (dry basis) of leaching slag. The leaching slag contains Li 2 O 0.12%, Rb 2 O 0.05%, Cs 2 O0.010%, K 2 O 0.40%, Li 2 O, Rb 2 O, Cs 2 O, K 2 O leaching rates were 96.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com