Compound vibration isolating device based on magnetic material and oil damping material

An oil damping and magnetic technology, which is applied to roads, tracks, ballast layers, etc., can solve the problems of poor vibration isolation effect of floating slab track, and achieve the effect of simple structure, good durability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

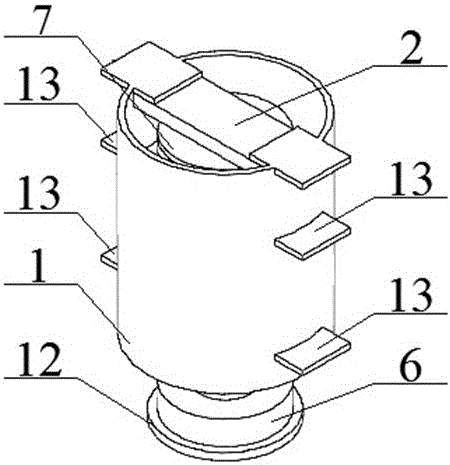

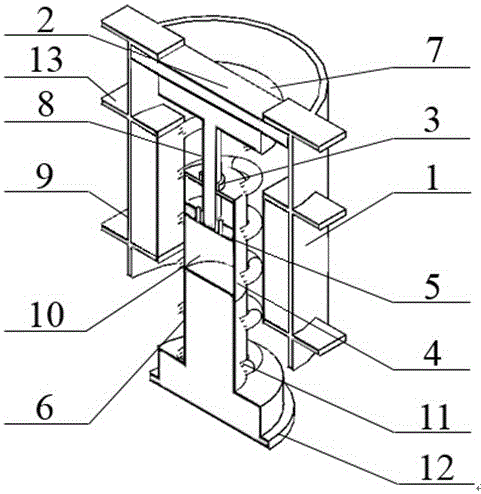

[0039] Such as Figure 1-6 As shown, the present invention is a composite vibration isolation device based on magnetic and oil damping materials, including a multifunctional sleeve 1, a baffle plate 2, an oil seal 3, a liquid cylinder 4, a filtrate plate 5, a ferromagnet 6, and a limit plate 7 , piston 8, permanent magnet 9, viscous material 10 (using silicone oil), steel spring 11, bottom plate 12, support plate 13.

[0040] The upper part of the piston 8 is a thick circular plate, and the lower part is a thin cylindrical rod. First, four upper and lower through holes are punched on the circular filtrate plate 5, and the lower end of the piston 8 is welded together with the filtrate plate 5; In the cylinder liquid cylinder 4 of opening, make the half length of the thin cylindrical rod of the bottom of filtrate plate 5 and piston 8 be positioned at liquid cylinder 4; The diameter of the lower rod) is symmetrically welded with the opening end of the hydraulic cylinder 4, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com