Large-section multifunctional hydraulic anchor bolt drill carriage

A bolt drilling rig, multi-functional technology, applied in the installation of bolts, drill pipes, drill pipes, etc., can solve the problems of many hidden dangers, bolt support driving, affecting the driving footage, etc., and achieve high safety factor and convenience. The effect of retractable and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

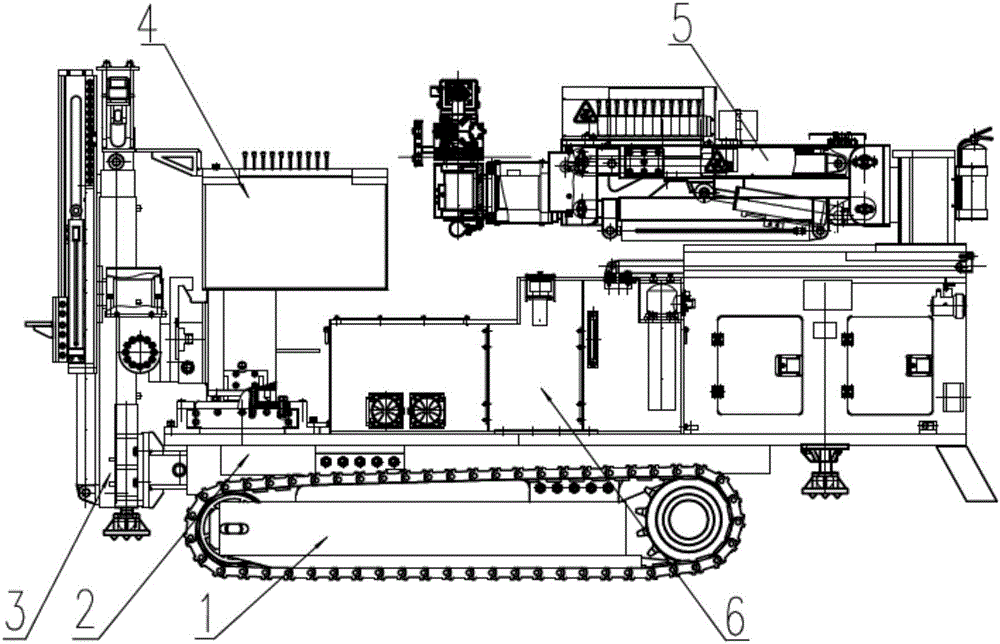

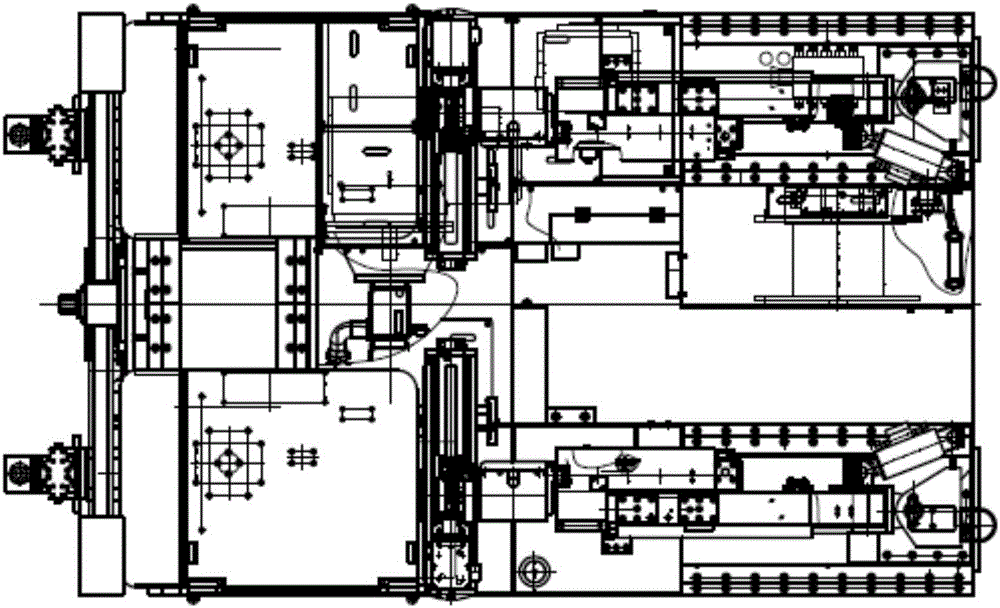

[0034] A large-section multifunctional hydraulic rock bolter, such as figure 1 and figure 2 As shown, it includes a running part 1, a body part 2, a front support part 3, two front drill arms 4, two rear drill arms 5 and a hydraulic system 6, the traveling mechanism 1 is arranged under the body part 2, and the two front drill arms The arms 4 are symmetrically arranged on the left and right sides of the front part of the body part 2, the two rear drilling arms 5 are symmetrically arranged on the left and right sides of the tail end of the body part 2, the hydraulic system 6 is arranged in the middle of the body part 2, and the front support part 3 is arranged on the the front end of the body part 2;

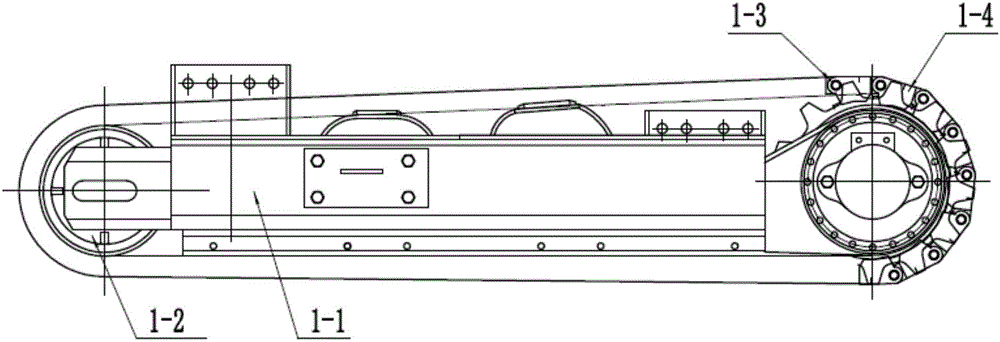

[0035] like image 3 and Figure 4 As shown, the walking part 1 is composed of two sets of left and right symmetrical walking mechanisms, and each set of walking mechanisms is composed of a crawler frame 1-1, a reversing sprocket 1-2, a driving sprocket 1-3, and a crawler belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com