Self-purification coke oven gas supergravity washing tower and self-purification coke oven gas benzene washing system

A self-purification technology for coke oven gas, which is applied in combustible gas purification, combustible gas purification/transformation, removal of gas pollutants, etc., and can solve problems such as high operating costs, low absorption efficiency, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

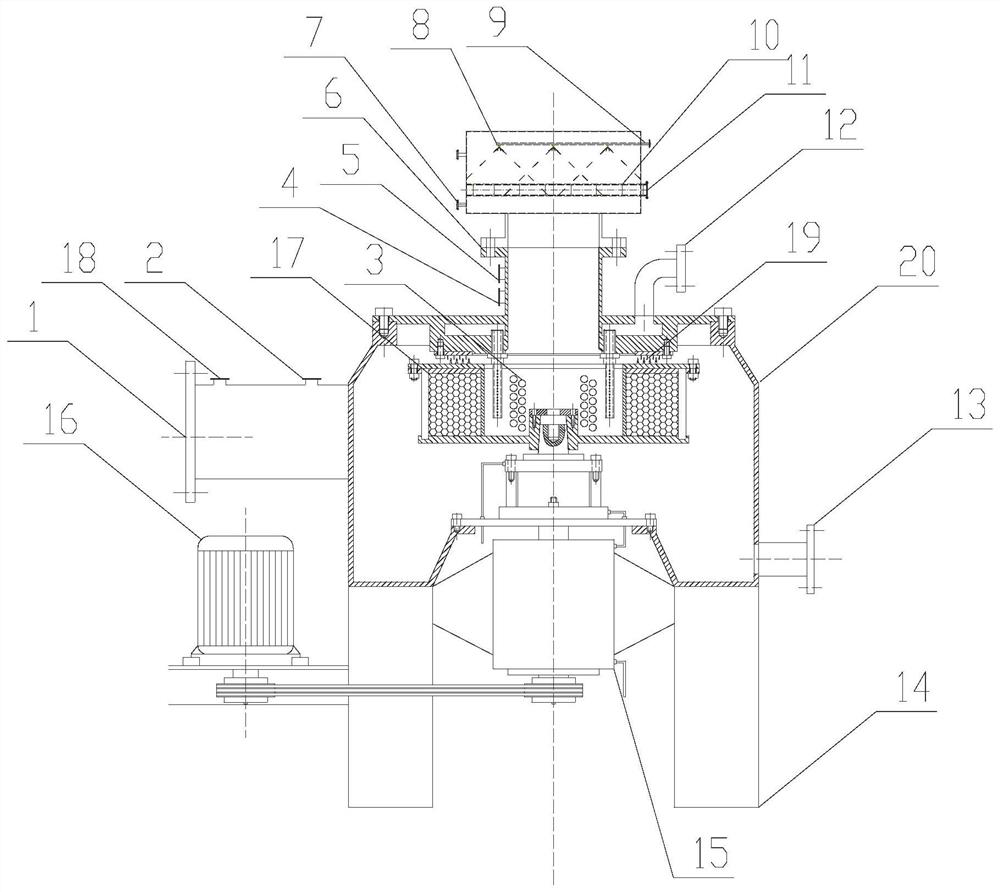

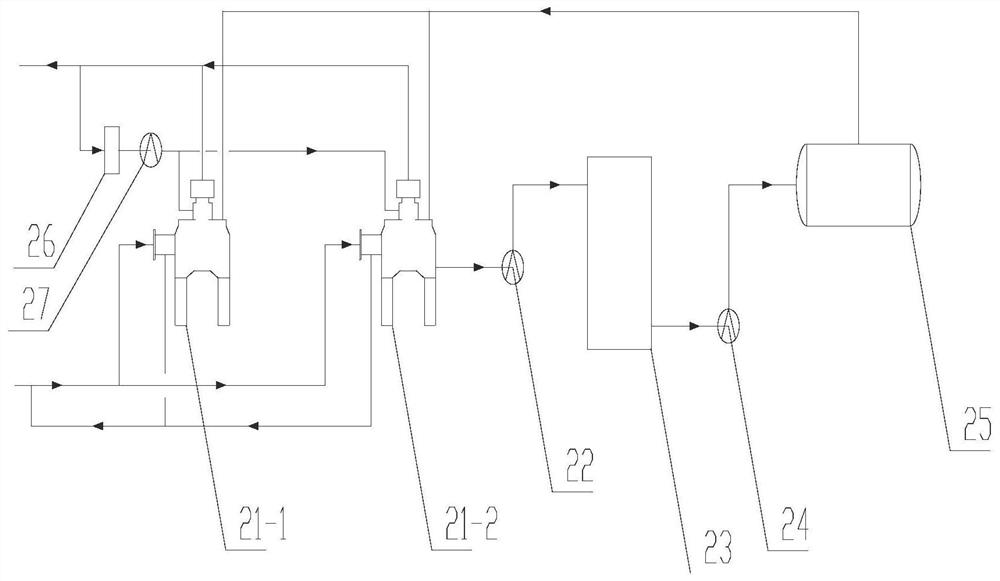

[0054] Such as figure 1 As shown, a self-purifying coke oven gas supergravity washing tower includes: a housing 20, a gas inlet passage, a gas outlet passage, a packing layer 17, a spray washing liquid inlet 12, a washing liquid outlet 13, a liquid distributor 19, a transmission Shaft and support frame 15, motor 16, built-in mist catcher 3, external mist catcher 10, and spray washing system with external mist catcher 10;

[0055] The packing layer 17 is arranged in the center of the housing, and a liquid distributor 19 is arranged above the packing layer, and the washing liquid enters the housing from the spray washing liquid inlet 12, and sprays the washing liquid onto the packing layer 17 through the connected liquid distributor 19, Wash the gas, after the washing is finished, the washing liquid flows out of the housing through the washing liquid outlet 13, and is sent to the next unit for regeneration of the washing liquid; Driven by motor 16;

[0056] The gas enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com