Model rocket engine

A technology for model rockets and engines, applied in rocket engine devices, machines/engines, teaching models, etc., can solve problems such as easy ignition of surrounding objects, accidents, poor safety and environmental protection, and achieve good smoking effect and safety. Good, low operating temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

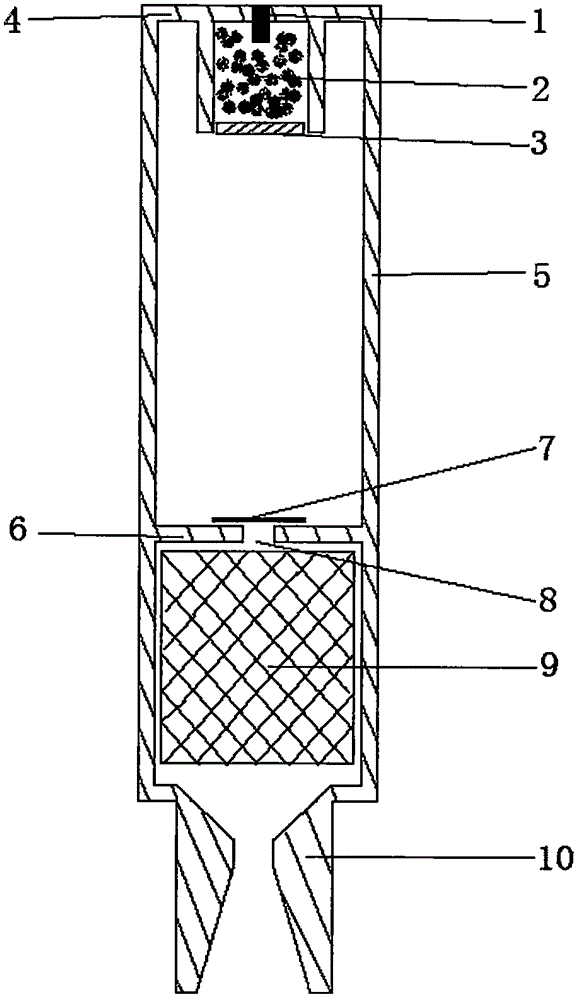

[0008] Embodiment 1: referring to accompanying drawing, a kind of model rocket motor comprises: the shell that is made up of tank top cover (4), tank casing (5) and nozzle (10); It is characterized in that: it also It includes: an electronic ignition head (1) located at the center of the top of the housing, catalyst sprinklers and catalyst particles (2) surrounding the electronic ignition head (1), and encapsulating the electronic ignition head (1) from below under normal conditions. The cap (3) of the catalyst particle (2) is arranged at the middle and lower position inside the housing and is used to close the storage tank bottom cover (6) of the storage tank housing (5), which is located at the storage tank bottom cover (6) The propellant inlet (8) in the center, the diaphragm (7) covering the propellant inlet (8), the working medium encapsulated inside the tank casing (5), is located on the tank bottom cover (6) Catalyst mesh thrust chamber (9) between the nozzle pipe (10)....

Embodiment 2

[0009] Embodiment 2: a kind of model rocket engine as described in embodiment 1, it is characterized in that: described catalyst particle (2) is potassium permanganate, and described working medium is hydrogen peroxide. After secondary catalysis in the catalyst mesh thrust chamber (9), it is completely decomposed into water vapor, and oxygen is ejected from the nozzle (10) at high speed to generate power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com