An axial flow compressor trailing edge circumferential air jet expansion device

A technology of axial flow compressor and jet device, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

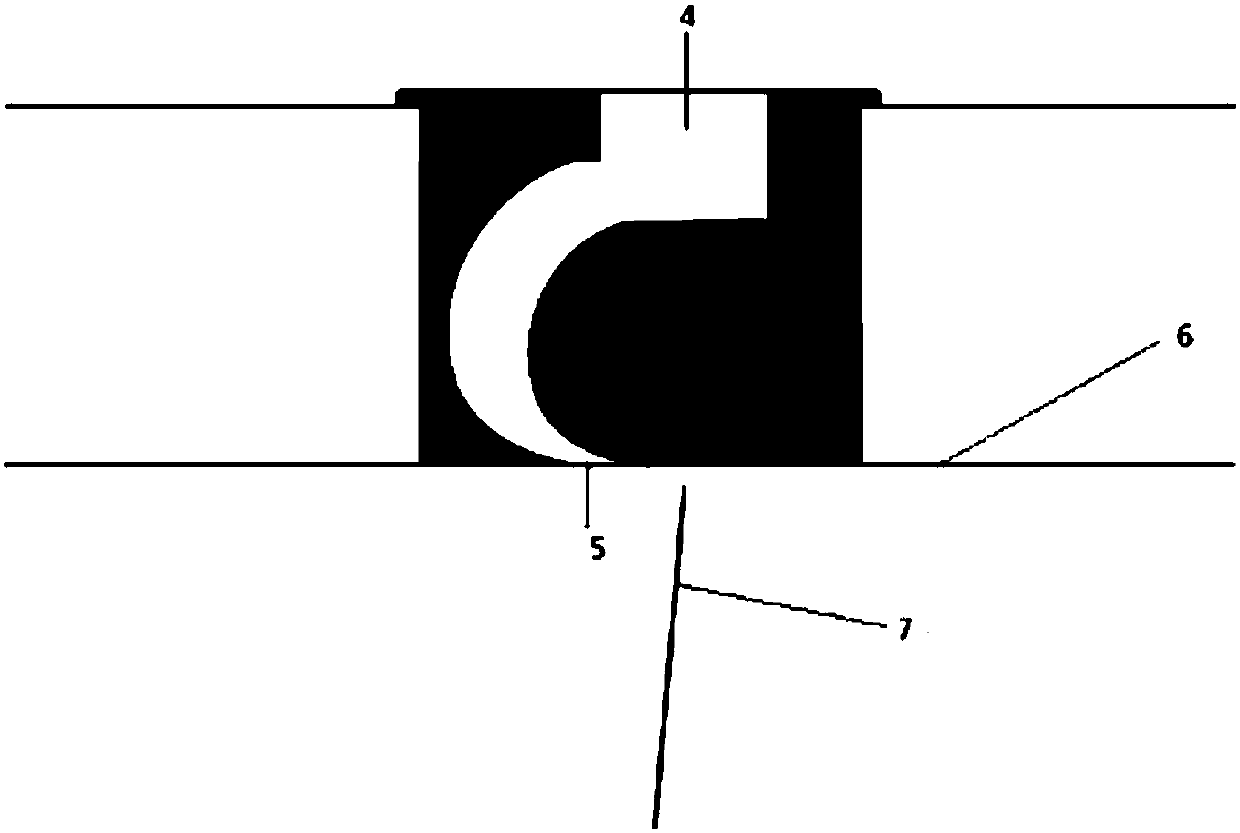

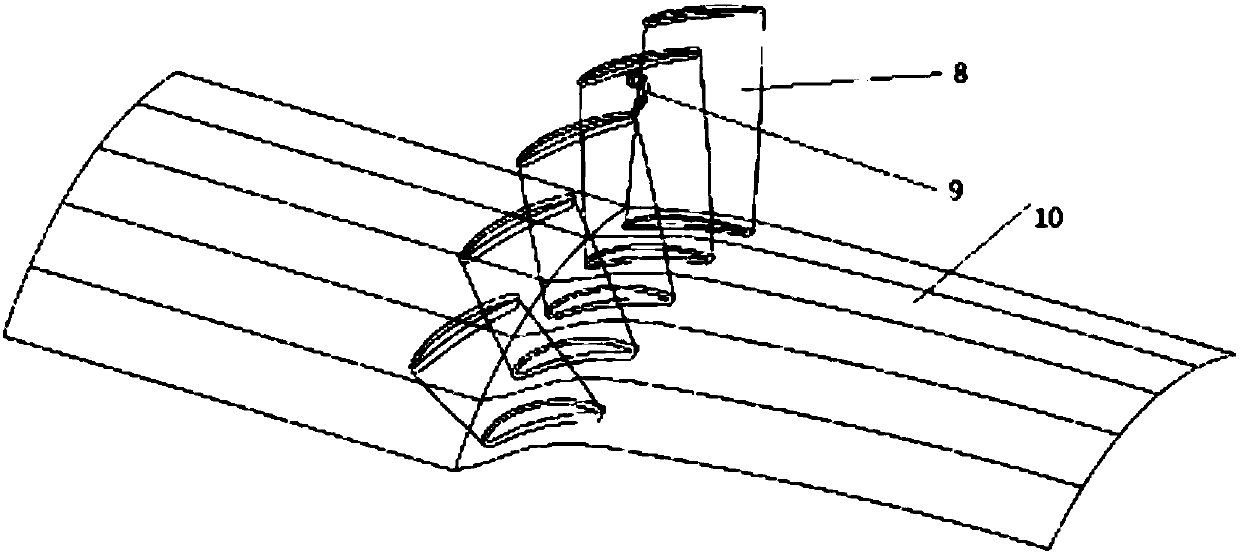

[0019] This embodiment is a circumferential air injection stabilization device at the trailing edge of an axial flow compressor.

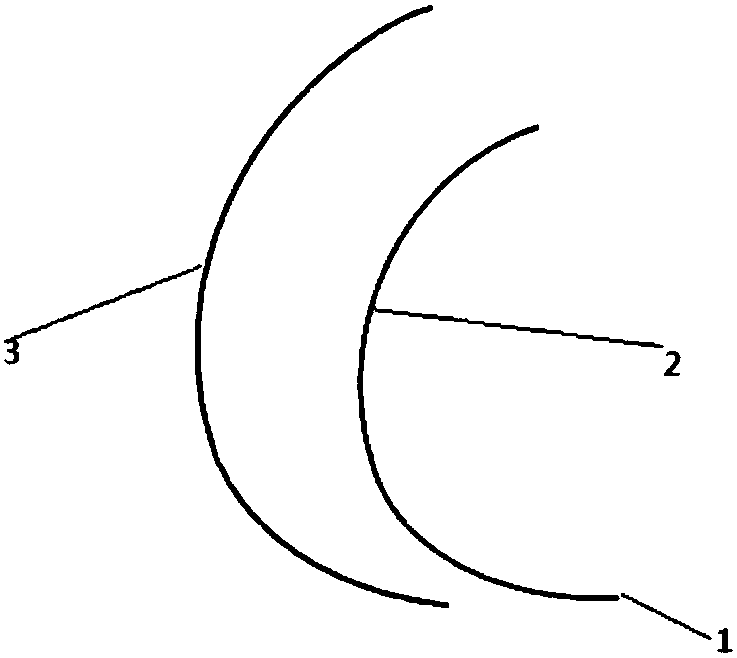

[0020] refer to Figure 1 to Figure 5 . In this embodiment, the stabilizing device for circumferential air injection at the trailing edge of the compressor is characterized in that an applicable air injection device is designed and the main parameters are optimized, so that the air injection effect is optimal. The jet device consists of a suction surface and a pressure surface;

[0021] The two-dimensional coordinates of the axial flow of the suction surface are 0, 0; -3.0229, 1.0806; -4.1305, 2.0129; -4.7016, 2.9021; 3.7778,7.2411;-2.9486,8.0215;0,9;

[0022] The two-dimensional coordinates of the pressure surface profile are 0, 0; -1.8099, 1.0248; -2.9042, 2.1635; -3.4826, 3.3022; 8.9958; -0.7886, 10.134; 0.73215, 10.972; 1.8957, 11.338; 2.4775, 11.4; other points are obtained by spline interpolation to form a spline curve. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com