SPE electrolytic cell module with composite flow field

A composite, electrolytic cell technology, applied in the direction of electrolytic components, electrolytic process, electrode shape/type, etc., can solve the problems of high working efficiency of membrane electrode, oxygen exhaust of anode bipolar plate, small pressure drop along the process, etc., to ensure The effect of liquid phase diffusion ability, high electrolysis efficiency and small pressure drop along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

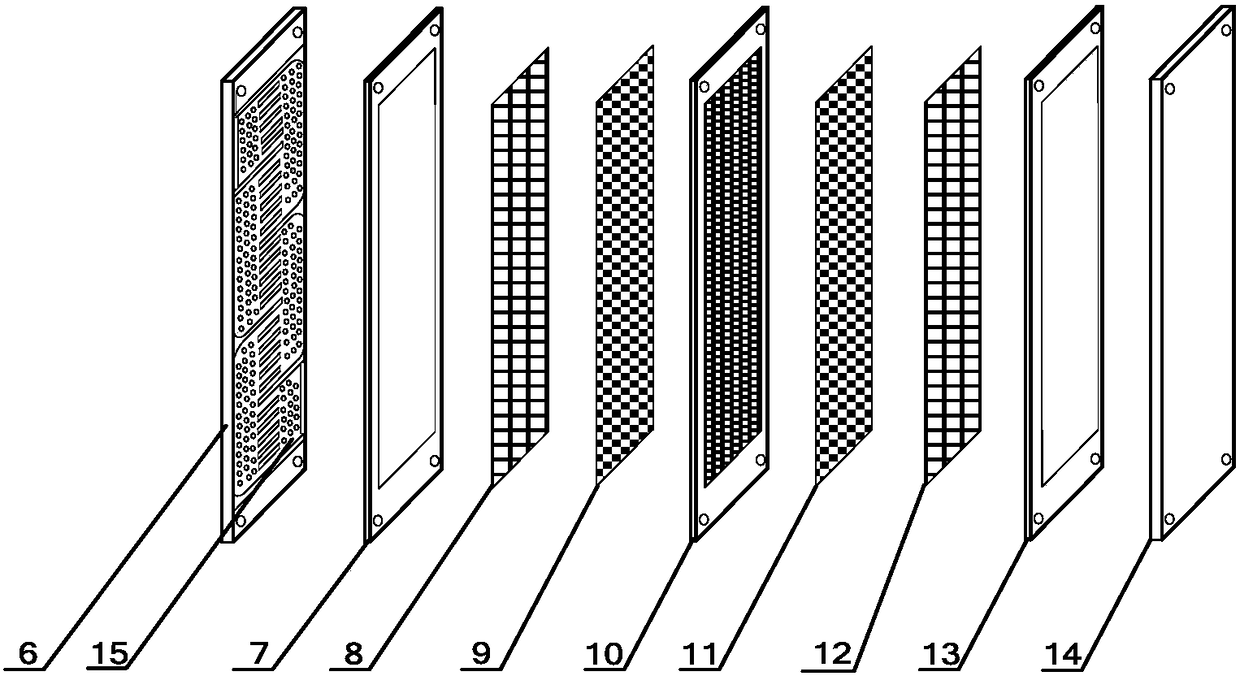

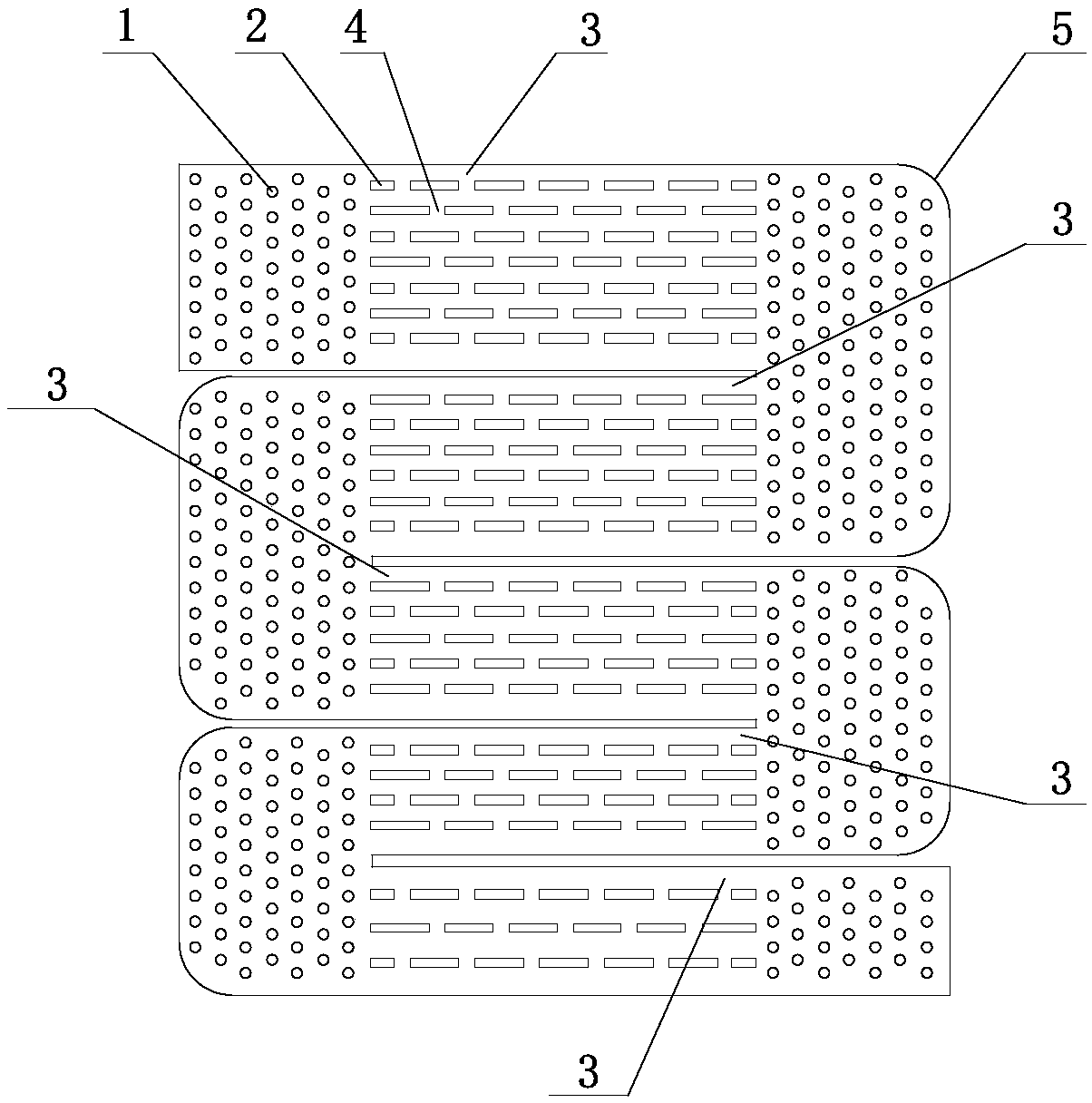

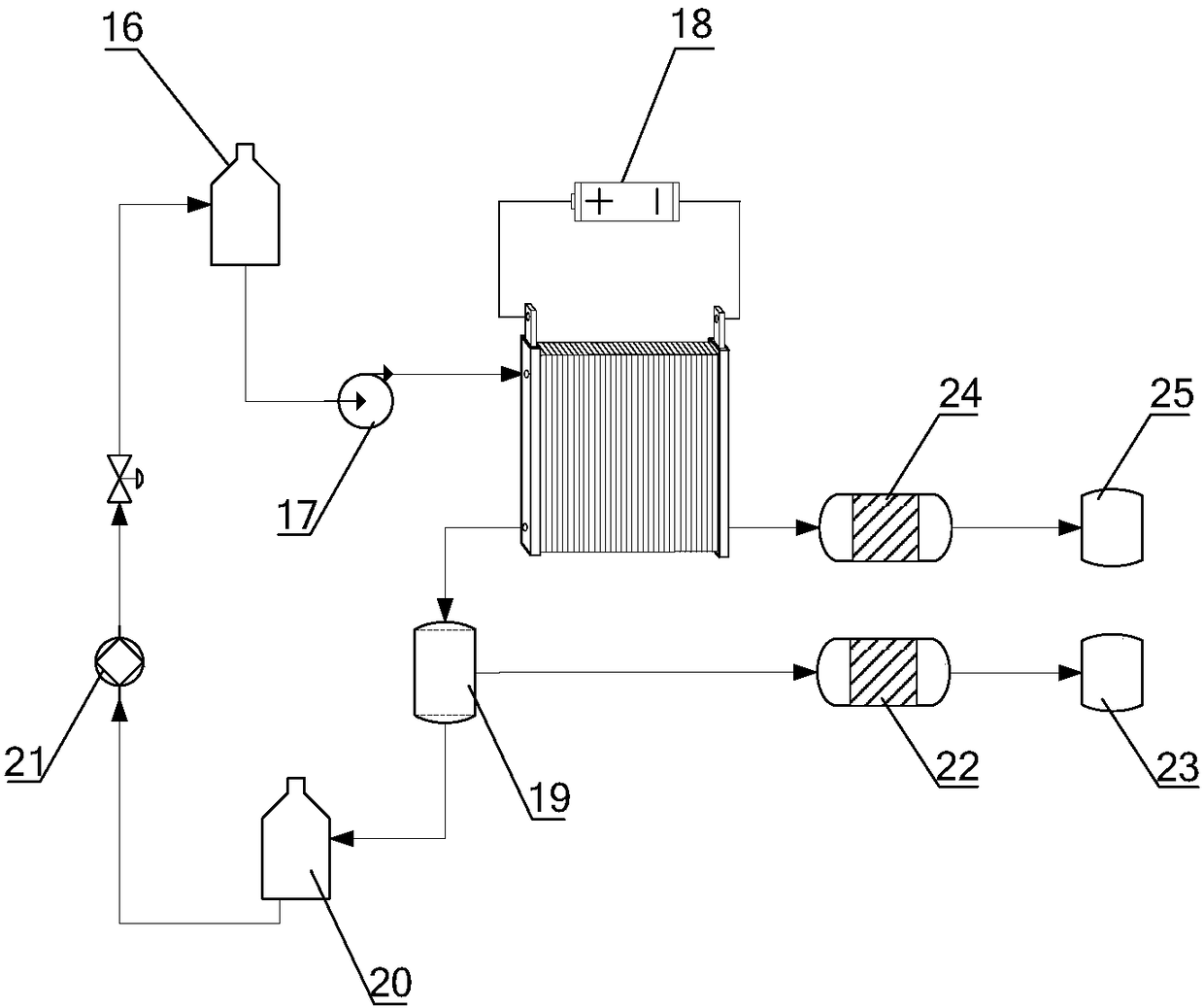

[0035] like figure 1 As shown, the present invention provides a novel SPE electrolytic cell module, which uses a composite flow field. The present invention comprises an anode bipolar plate 6 , an anode diffusion layer 8 , a proton exchange membrane 10 , a cathode catalyst layer 11 , a cathode diffusion layer 12 and a cathode bipolar plate 14 which are assembled sequentially. The anode bipolar plate 6 is engraved with an anode bipolar plate flow channel 15, and the cathode bipolar plate 14 is engraved with a cathode bipolar plate flow channel, wherein the anode bipolar plate flow channel is respectively provided with A pure water inlet and a water oxygen outlet, while the cathode bipolar plate flow channel only has a hydrogen outlet. The diffusion layer, catalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com