Spline shaft for rotor and stator separation technology of parallel-connection hydrodynamic retarder

A hydraulic retarder, rotor stator technology, applied in the direction of shaft, shaft and bearing, mechanical equipment, etc., to achieve the effect of clear function, flexible adjustment space, and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

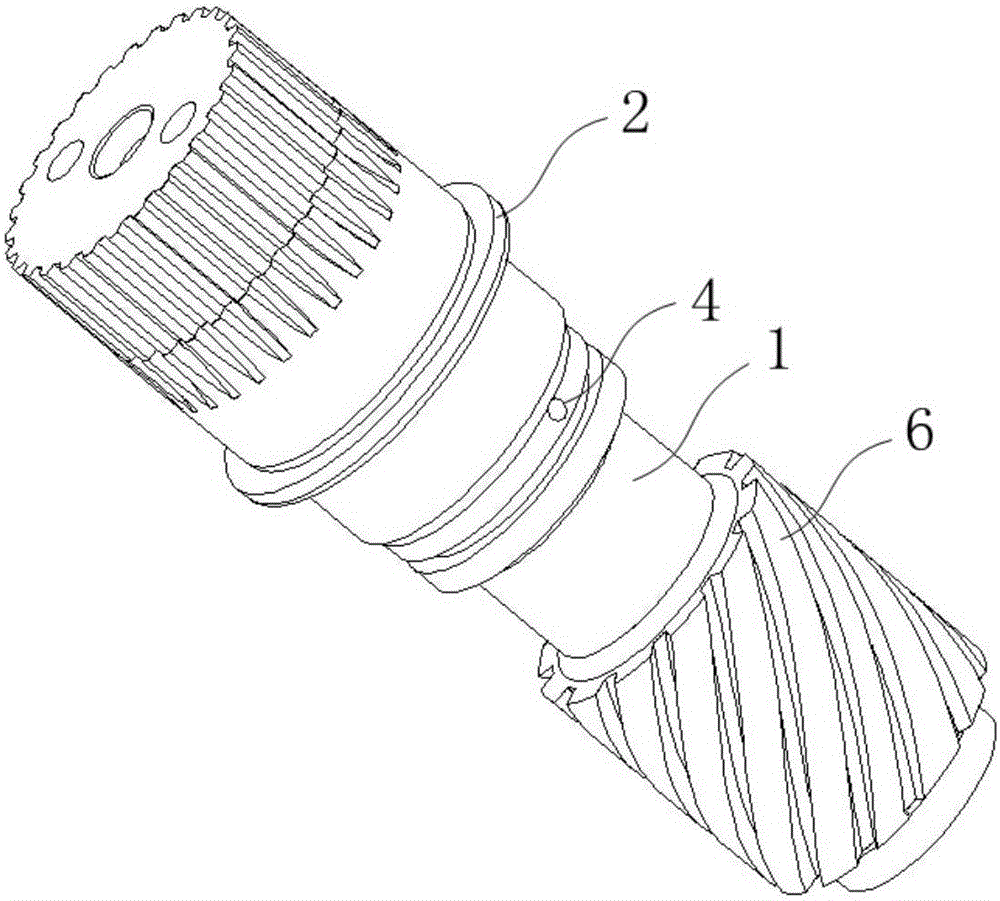

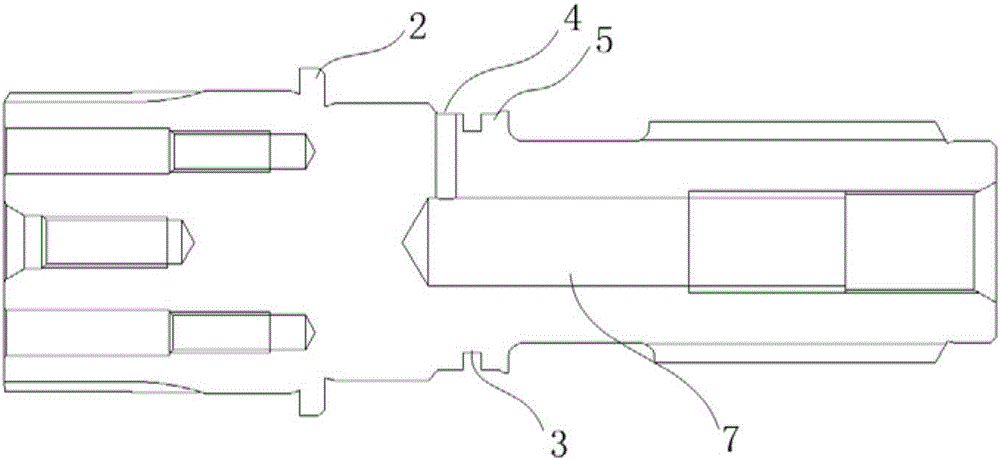

[0017] Such as figure 1 , 2 As shown, the present invention discloses a spline shaft used for rotor-stator separation technology of a parallel hydraulic retarder, including a spline main shaft 1, a limit ring 2, a rotor impeller limit platform 5, a spline main shaft 1 and two The ends are the spline end and the multi-thread end respectively, and the limit ring 2 and the rotor impeller limit platform 5 are arranged respectively from the spline end to the multi-thread end, and an oil seal is set between the limit ring 2 and the rotor impeller limit platform 5 Ring groove 3 and oil cavity through hole 4, the central axis of spline main shaft 1 is provided with threaded hole 7 from multi-start thread end to spline end, and spline main shaft 1 is provided with several multi-start threads 6 away from spline end.

[0018] The multi-start thread 6 has a reverse helical structure, and the number of multi-start threads 6 is 11, wherein the helix angle is 35.52°, the modulus is 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com