Sealed pipeline

A technology for sealing pipes and plastic pipes, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc. sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

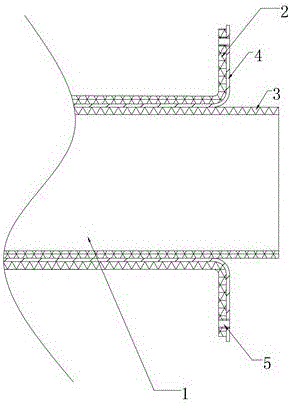

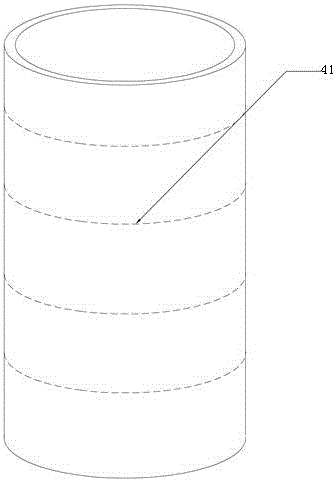

[0016] The reference signs in the accompanying drawings of the specification include: plastic pipe body 1 , connection part 2 , insertion part 3 , copper cylinder 4 , and pre-cutting line 41 .

[0017] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0018] The sealed pipeline in this scheme includes a plastic pipeline body 1, and the plastic pipeline body 1 includes an inner ring and an outer ring, and a copper tube 4 is arranged between the inner ring and the outer ring. The pre-cutting line 41 parallel to the end surface of the tube 4 is evenly arranged along the central axis of the copper tube 4, and the right end of the copper tube 4 protrudes from the plastic pipe body 1; the right end of the copper tube 4 is turned outward to form a flanging, and the plastic The port part of the pipeline body 1 includes a connecting part 2 and an inserting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com