Antifreezing heat pipe air heater system

A heater and heat pipe technology, applied in the field of heater systems, can solve problems such as leakage of condensed water in the heater, endangering the operation of the air preheater, and failure of online maintenance of the heater, so as to prevent the freeze of the heat pipe and facilitate online maintenance. Repair and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

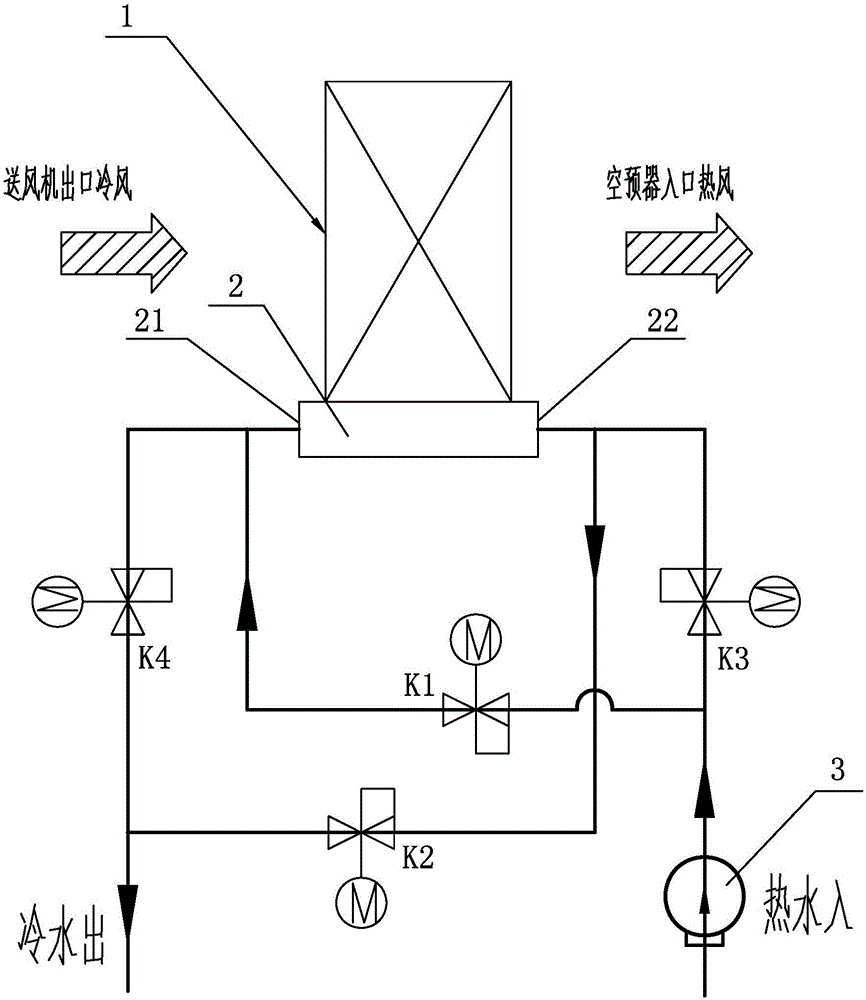

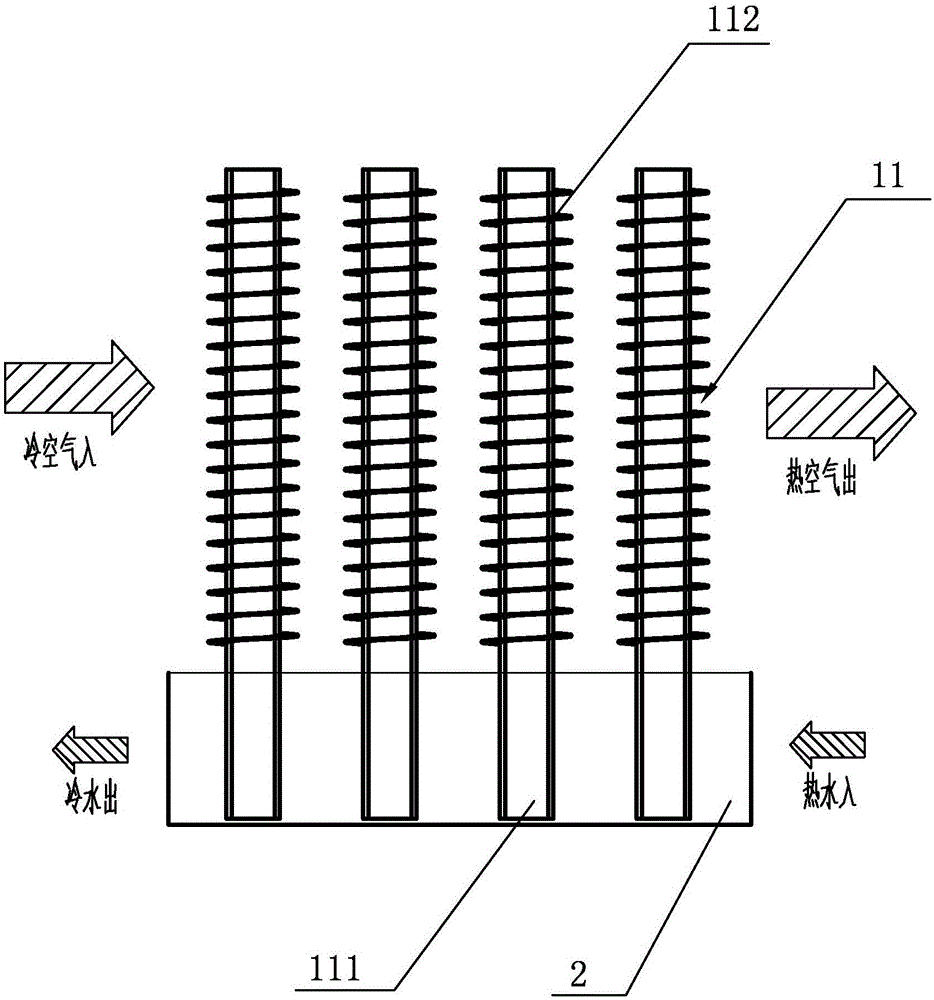

[0023] A kind of antifreeze type heat pipe heater system that present embodiment proposes, as figure 1 and figure 2 As shown, it includes a heat pipe heater body 1 composed of a plurality of mutually independent and vertically arranged heat pipes 11, a heater water chamber 2 with a first water opening 21 and a second water opening 22, and downstream heat exchange. Control circuit and countercurrent heat exchange control circuit, the air inlet of the heat pipe heater body 1 is connected to the air outlet of the external blower, the hot air output from the air outlet of the heat pipe heater body 1 is supplied to the external air preheater, and the heat pipe heater The air heater body 1 uses low-grade hot water as a heat source, and the lower parts of all heat pipes 11 extend into the air heater water chamber 2, and the downstream heat exchange control lines are respectively connected to the first water outlet 21 and the second water outlet 22, and When the temperature of the a...

Embodiment 2

[0028] The antifreeze type heat pipe heater system proposed in this embodiment has the same structure as that of the antifreeze type heat pipe heater system in Embodiment 1, the only difference is that the length of the finned tube 112 is ten times the length of the heat pipe 11 Nine-tenths, that is, the length of the light pipe 111 is one-tenth of the length of the heat pipe 11 .

Embodiment 3

[0030] The antifreeze type heat pipe heater system proposed in this embodiment is the same as other structures of the antifreeze type heat pipe heater system in Embodiment 1, the only difference is that the length of the finned tube 112 is three times the length of the heat pipe 11 Thirty-one fifteenths, that is, the length of the light pipe 111 is four thirty-fifths of the length of the heat pipe 11 .

[0031] The working process of the antifreeze type heat pipe heater system of the present invention is: when the temperature of the air is higher than -20°C, the first gate valve and the second gate valve are closed, the third gate valve and the fourth gate valve are opened, and the low-grade hot water passes through the The pressure pump enters the third gate valve, and then enters the water chamber of the air heater. The hot water in the water chamber of the air heater heats the antifreeze liquid working medium in all heat pipes. In the sheet tube, after exchanging heat with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com