Method for detecting content of hexavalent chromium ions in passivating solution

A hexavalent chromium ion and detection method technology, which is applied in the field of detection of hexavalent chromium ion content in passivation solution, can solve the problems of affecting the accuracy of results, relevant certification obstacles, and great interference of colorimetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

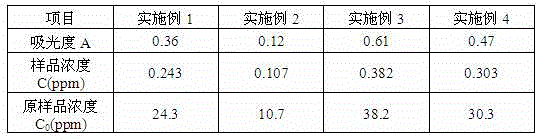

Examples

Embodiment 1

[0021] A detection method for hexavalent chromium ion content in passivation solution, comprising the following steps:

[0022] (1) Accurately measure 1mL of sample 1, add 3mL of 10wt% 5-Br-PADAP ethanol solution and 10mL of sodium carbonate-sodium bicarbonate solution with a pH of 9 to sample 1, and stir for 10 minutes;

[0023] (2) The solution after the reaction is introduced into a separatory funnel, and 10 mL of chloroform is added for extraction three times at a time, the aqueous phase and the organic phase are separated, and the aqueous phase is collected;

[0024] (3) adjust the pH of the aqueous phase to 2.5 with sulfuric acid;

[0025] (4) Add diphenylcarbazide acetone solution to develop color, and set the volume to 100 mL;

[0026] (5) Measure the absorbance at 540nm after the sample is color developed and constant volume with a UV-visible spectrophotometer, and calculate the sample Cr 6+ content.

Embodiment 2

[0028] A detection method for hexavalent chromium ion content in passivation solution, comprising the following steps:

[0029] (1) Accurately measure 1mL of sample 2, add 3mL of 10wt% 5-Br-PADAP ethanol solution and 10mL of sodium carbonate-sodium bicarbonate solution with a pH of 9 to sample 2, and stir for 30min;

[0030] (2) The solution after the reaction is introduced into a separatory funnel, and 10 mL of chloroform is added for extraction three times at a time, the aqueous phase and the organic phase are separated, and the aqueous phase is collected;

[0031] (3) adjust the pH of the aqueous phase to 1.5 with sulfuric acid;

[0032] (4) Add diphenylcarbazide acetone solution to develop color, and set the volume to 100 mL;

[0033] (5) Measure the absorbance at 540nm after the sample is color developed and constant volume with a UV-visible spectrophotometer, and calculate the sample Cr 6+ content.

Embodiment 3

[0035] A detection method for hexavalent chromium ion content in passivation solution, comprising the following steps:

[0036] (1) Accurately measure 1mL of sample 3, add 3mL of 10wt% 5-Br-PADAP ethanol solution and 10mL of sodium carbonate-sodium bicarbonate solution with a pH of 9 to sample 3, and stir for 20 minutes;

[0037] (2) The solution after the reaction is introduced into a separatory funnel, and 10 mL of chloroform is added for extraction three times at a time, the aqueous phase and the organic phase are separated, and the aqueous phase is collected;

[0038] (3) adjust the pH of the aqueous phase to 2 with sulfuric acid;

[0039] (4) Add diphenylcarbazide acetone solution to develop color, and set the volume to 100 mL;

[0040] (5) Measure the absorbance at 540nm after the sample is developed and constant volume by UV-visible spectrophotometer, and calculate the sample Cr 6+ content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com