Ion exchange membrane with monovalent ion selectivity and preparing method and application thereof

An ion-exchange membrane and ion-selective technology, which is applied in the field of ion-exchange membrane with monovalent ion selectivity and its preparation, can solve problems such as reducing the current efficiency of electrodialysis, affecting ion separation, increasing membrane surface resistance, etc., and achieving electrochemical The effect of controllable performance and controllable separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for preparing an ion-exchange membrane with monovalent cation selectivity, the method comprising the following steps:

[0062] (1) 0.2 g / L nano-graphene and cationic polyelectrolyte polydimethyldiallyl ammonium chloride (PDDA) with a concentration of 2 g / L were blended by mechanical stirring and ultrasonic to form a uniform cationic polyelectrolyte mixed solution , add 1mol / L sodium chloride solution in the solution to adjust the ionic strength;

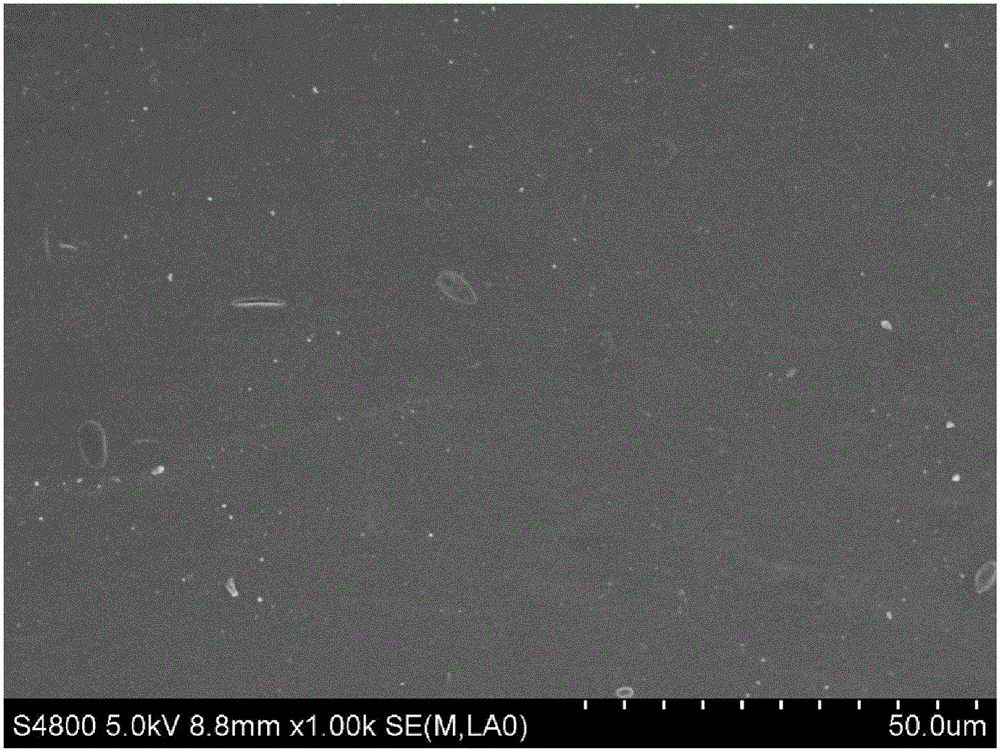

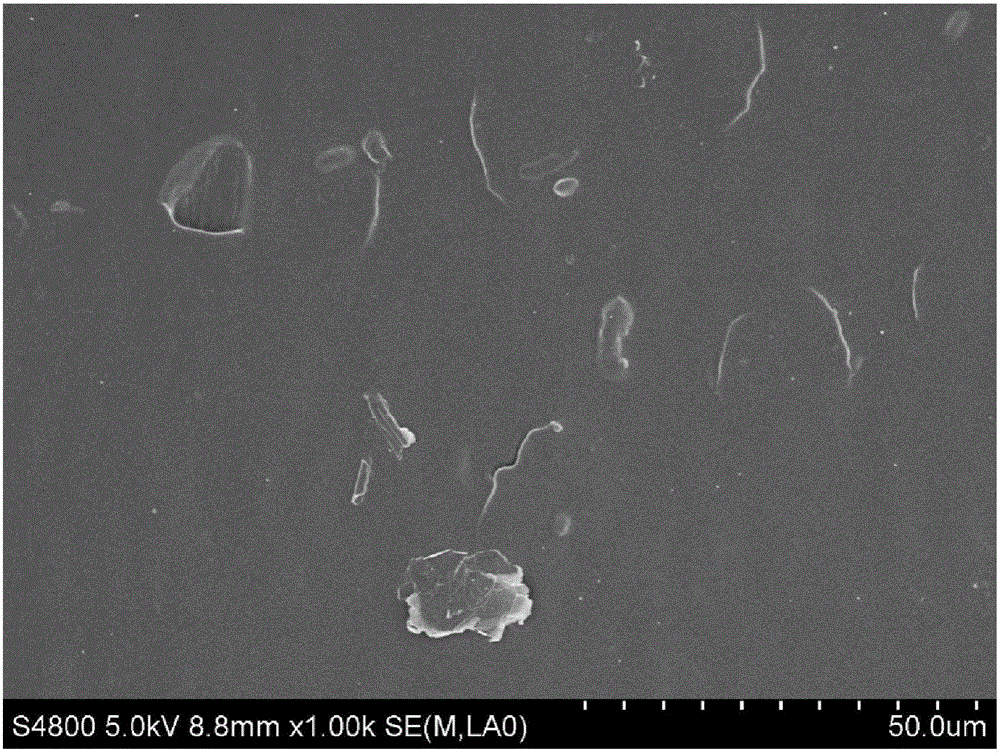

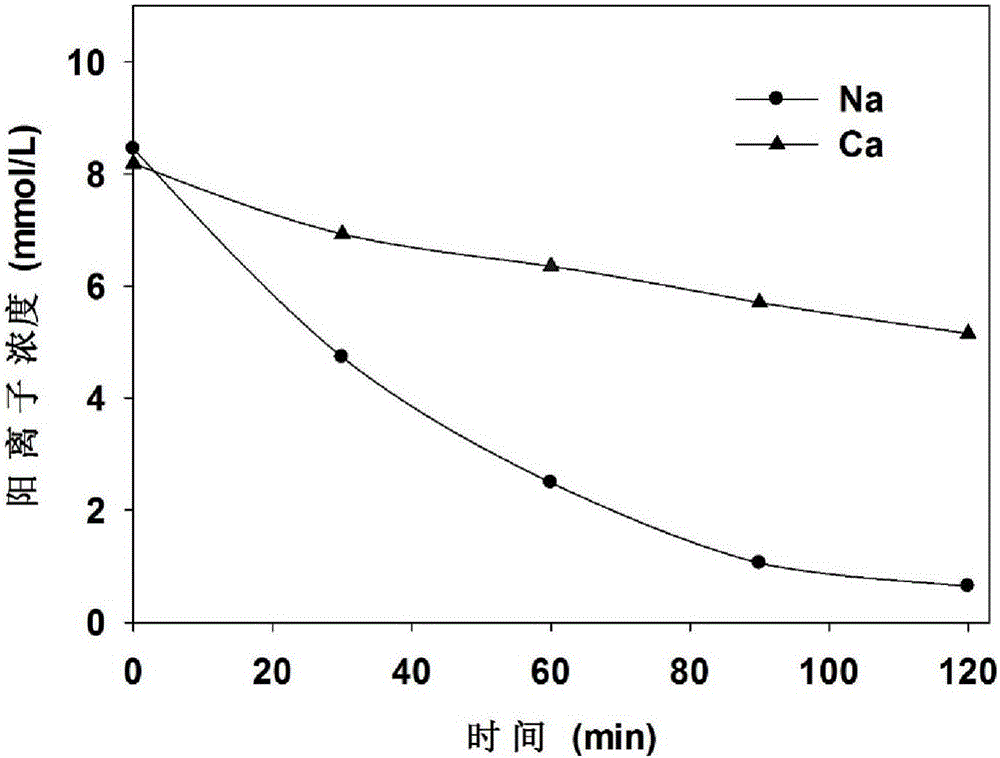

[0063] (2) In the cation exchange membrane (commercial, its scanning electron microscope picture is as figure 1 Shown) the surface is deposited by the layer-by-layer self-assembly method of the cationic polyelectrolyte mixed solution prepared in step (1), and then deposits 2g / L of anionic polyelectrolyte polystyrene sulfonate sodium (PSS), and adds 1mol / L sodium chloride solution to adjust the ionic strength, and the adsorption time of each layer is 15min. After each layer is deposited, rins...

Embodiment 2

[0067] This embodiment provides a method for preparing an ion-exchange membrane with monovalent cation selectivity, the method comprising the following steps:

[0068] (1) 0.2g / L nano-graphene and anionic polyelectrolyte sodium polystyrene sulfonate (PSS) with a concentration of 2g / L are blended by mechanical stirring and ultrasonic to form a uniform anionic polyelectrolyte mixed solution, and 1mol / L of sodium chloride solution to adjust the ionic strength;

[0069] (2) Deposit the cationic polyelectrolyte polydimethyldiallyl ammonium chloride (PDDA) of 2g / L by the layer-by-layer self-assembly method on the surface of the cation exchange membrane, and then the anionic polyelectrolyte prepared in step (1) Mix the solution, add 1mol / L sodium chloride solution to the solution to adjust the ionic strength, the adsorption time of each layer is 15min, after the deposition of each layer, rinse the undeposited conductive nanoparticles and free polyelectrolyte with ionized water, and ...

Embodiment 3

[0071] This embodiment provides a method for preparing an ion-exchange membrane with monovalent cation selectivity, the method comprising the following steps:

[0072] (1) 0.2 g / L nano-graphene and cationic polyelectrolyte polydimethyldiallyl ammonium chloride (PDDA) with a concentration of 2 g / L were blended by mechanical stirring and ultrasonic to form a uniform cationic polyelectrolyte mixed solution , 0.2g / L nanometer graphene and the anionic polyelectrolyte polystyrene sulfonate sodium (PSS) that concentration is 2g / L form the homogeneous anionic polyelectrolyte mixed solution by mechanical stirring and ultrasonic blending, add to two kinds of solutions respectively 1mol / L sodium chloride solution to adjust the ionic strength;

[0073] (2) On the surface of the cation exchange membrane, the cationic polyelectrolyte mixed solution prepared in the layer-by-layer self-assembly method is deposited in step (1), and then the anionic polyelectrolyte mixed solution prepared in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com