A method and equipment for separating waste lithium-ion battery winding core and casing

A lithium-ion battery and separation equipment technology, which is applied in the field of lithium-ion batteries, can solve the problems of bulging battery shape, high cutting knife material and hardness requirements, short-circuit ignition of battery cells, etc., and achieve the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for separating waste lithium-ion battery winding cores and casings, comprising the following steps:

[0045] (1) Fix the square lithium battery horizontally, and make its cover 2mm outside the fixing table;

[0046] (2) Use a cutter to cut the upper and lower end faces of the square lithium battery case below the cover at the same time. The depth of the cut is 40% of the wall thickness of the case, resulting in incomplete cut marks;

[0047] (3) Fix the cover plate of the square lithium battery, and use a thimble to insert the explosion-proof hole on the cover plate of the square lithium battery, and pass high-pressure inert helium gas with a pressure of 6Kg into it to break the cut mark, and The casing of the prismatic lithium battery is washed off by high-pressure gas and separated;

[0048] (4) Cut off the tab between the cover plate and the core to separate the cover plate from the core.

Embodiment 2

[0050] A method for separating waste lithium-ion battery winding cores and casings, comprising the following steps:

[0051] (1) Fix the square lithium battery horizontally, and make its cover 3mm outside the fixing table;

[0052] (2) Use a cutter to cut the upper and lower end faces of the square lithium battery case below the cover at the same time. The depth of the cut is 60% of the wall thickness of the case, resulting in incomplete cut marks;

[0053] (3) Fix the cover plate of the square lithium battery, and use a thimble to insert into the explosion-proof hole on the cover plate of the square lithium battery, and pass high-pressure inert nitrogen gas with a pressure of 10Kg into it to break the cut mark and make it The casing of the prismatic lithium battery is washed down by high-pressure gas and separated;

[0054] (4) Cut off the tab between the cover plate and the core to separate the cover plate from the core.

Embodiment 3

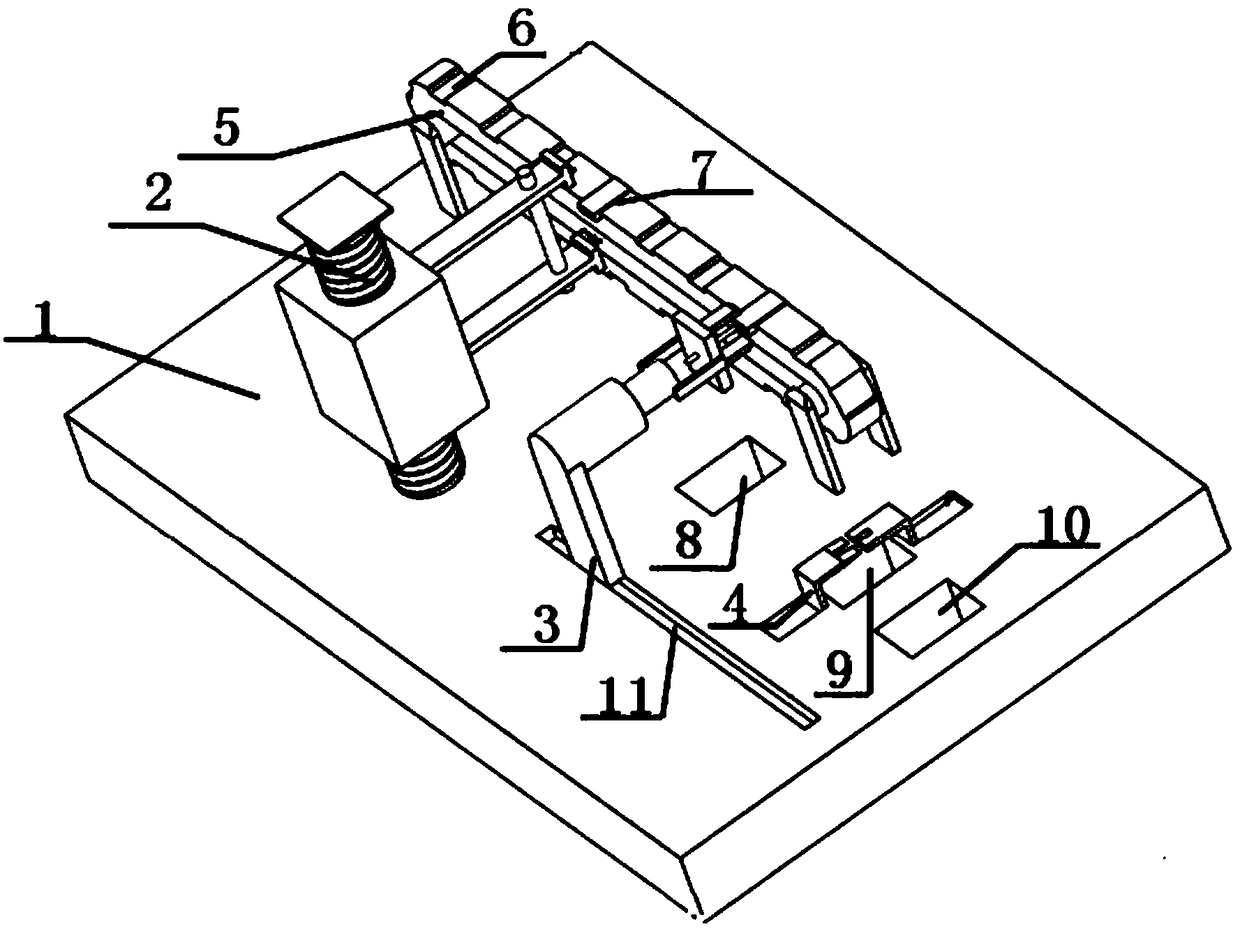

[0056] Such as figure 1 As shown, a separation device for waste lithium-ion battery winding cores and shells includes a working platform 1, a conveyor belt 5 is fixed on one side of the working platform 1, and a square conveyor belt 5 is fixed on the other side of the working platform 1. The shell of the lithium battery 7 is cut and blasted by a pre-cutting mechanism 2 and a high-pressure blasting mechanism 3. The working platform 1 located directly below the high-voltage blasting mechanism 3 is provided with a shell discharge port 8, which is far away from the work at the end of the pre-cutting mechanism 2. The platform 1 is provided with a winding core discharge port 9 and a cover plate discharge port 10 in sequence; a tab cutting mechanism 4 for cutting the tabs of the square lithium battery 7 is fixed above the core discharge port 9 .

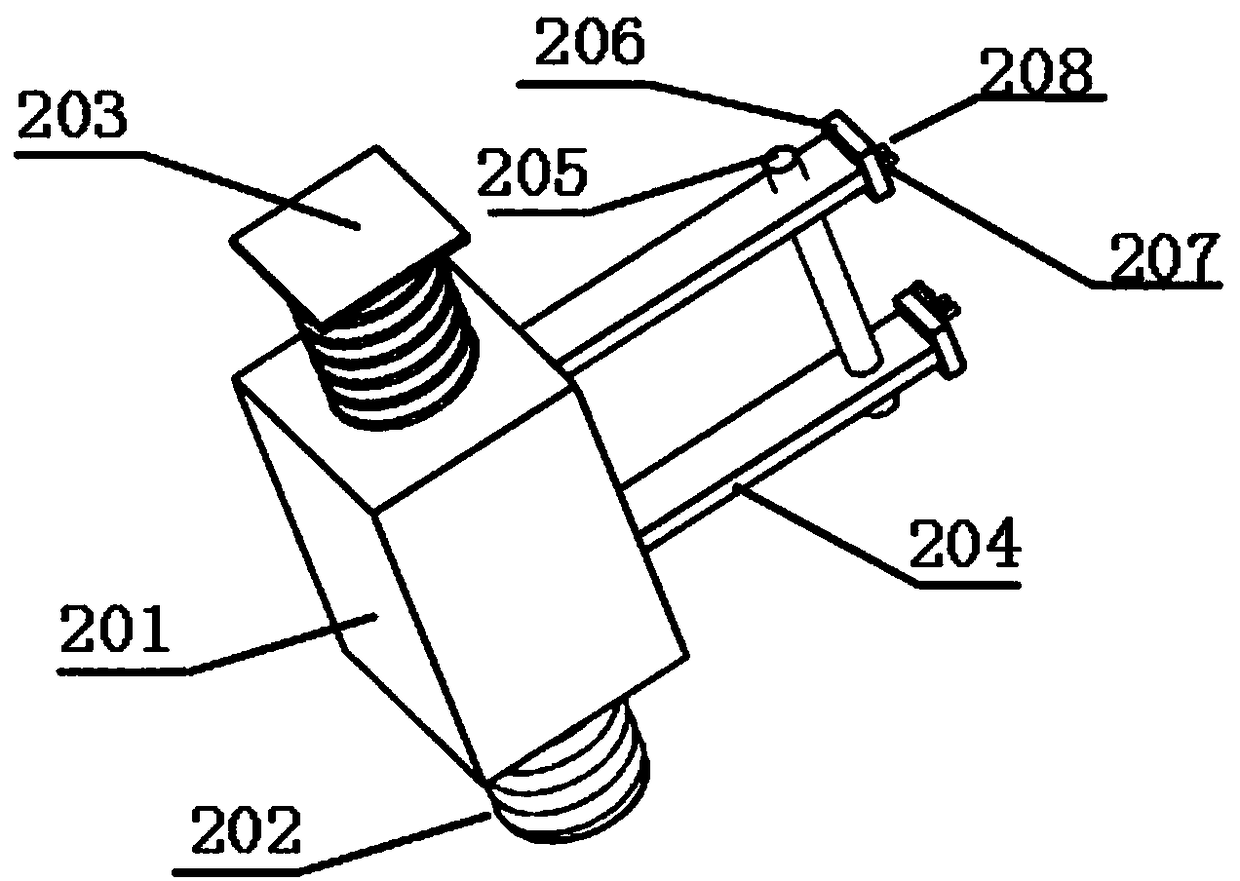

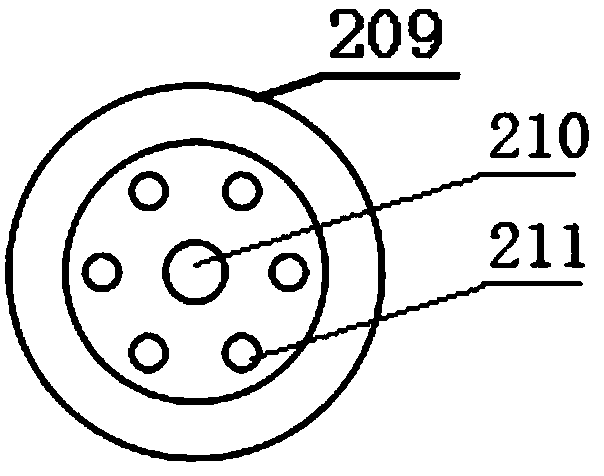

[0057] Such as figure 2 As shown, the pre-cutting mechanism 2 includes a pillar 203 and a circular cutter 209 fixed on the working platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com