Automatic thermocouple battery thermal management system

An automatic management and thermocouple technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex calculation mode, limit heat absorption of insulation jackets, and inability to achieve heat exchange, achieving low cost and broad application prospects. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the stated scope.

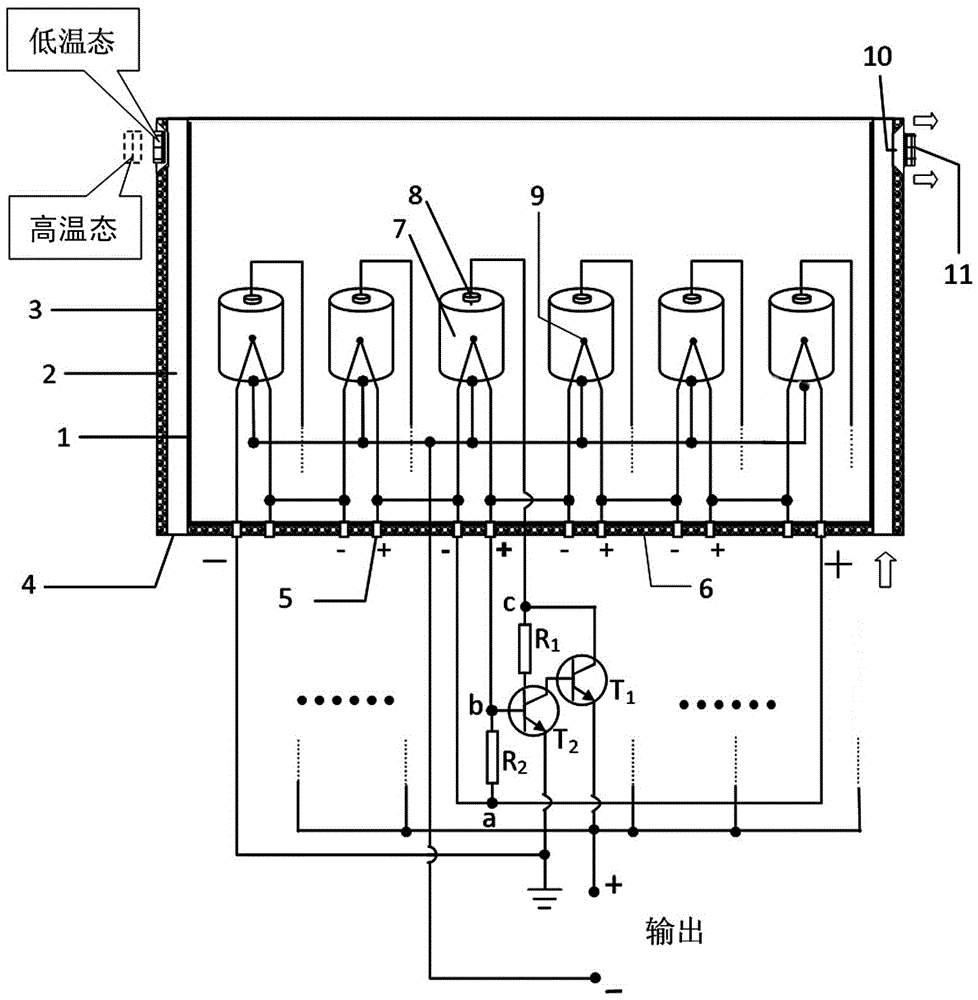

[0018] In the present invention, the inner wall 1 of the battery box and the outer shell 3 form a battery box combination with interlayers on the sides. A series of single cells 7 are arranged in the space on the inner wall of the box. Ventilation window 10, bimetal temperature regulating sheet 11 is contained in the ventilation window 10 place and matches with it. The air convection layer 2 of the interlayer of the battery box body is closed at the top, and an interlayer opening hole 4 is provided at the lower end. The cross section of the ventilation window 10 is a trapezoidal structure with a small inside and a large outside. The bottom layer 6 of the battery box is embedded with the thermocouple voltage output terminal 5, which is welded with two identical thermocouple com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com