Grating-shaped kneading cylinder for persimmon kneading machine

A technology of kneading machine and grille, applied in application, food processing, food science and other directions, can solve the problems of downstream influence, stalk falling off, small impact degree, etc., to ensure quality, improve production speed, and enhance effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

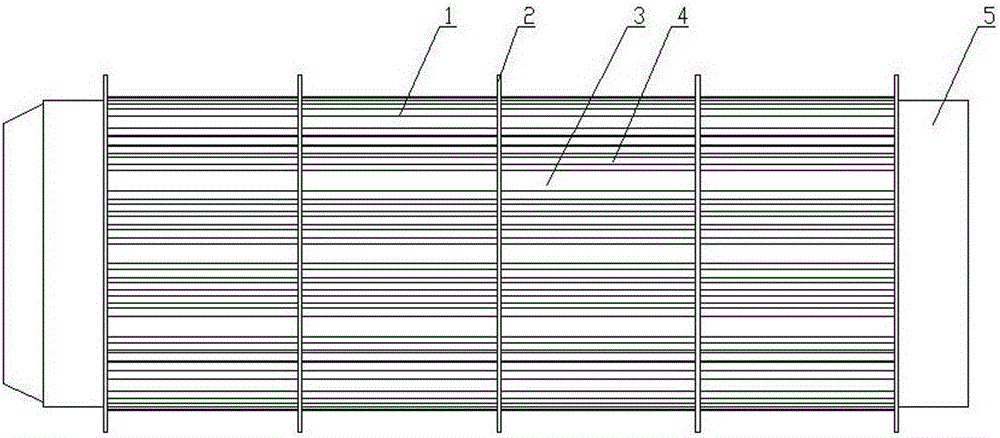

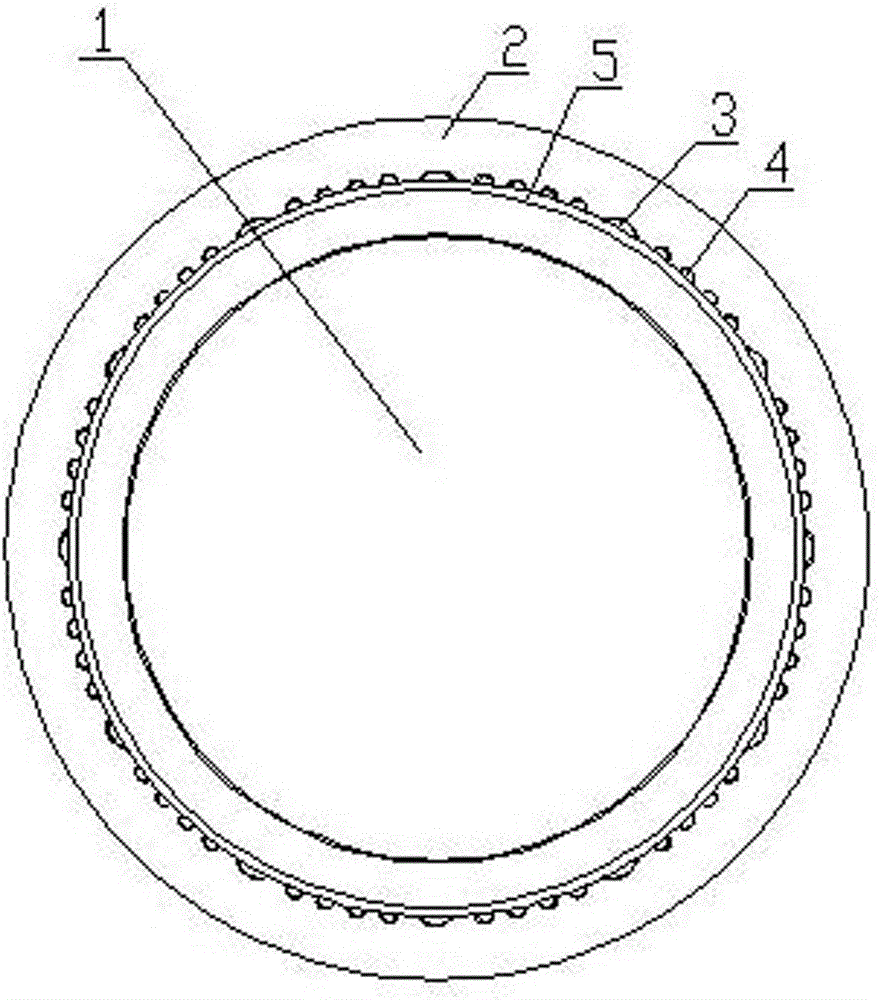

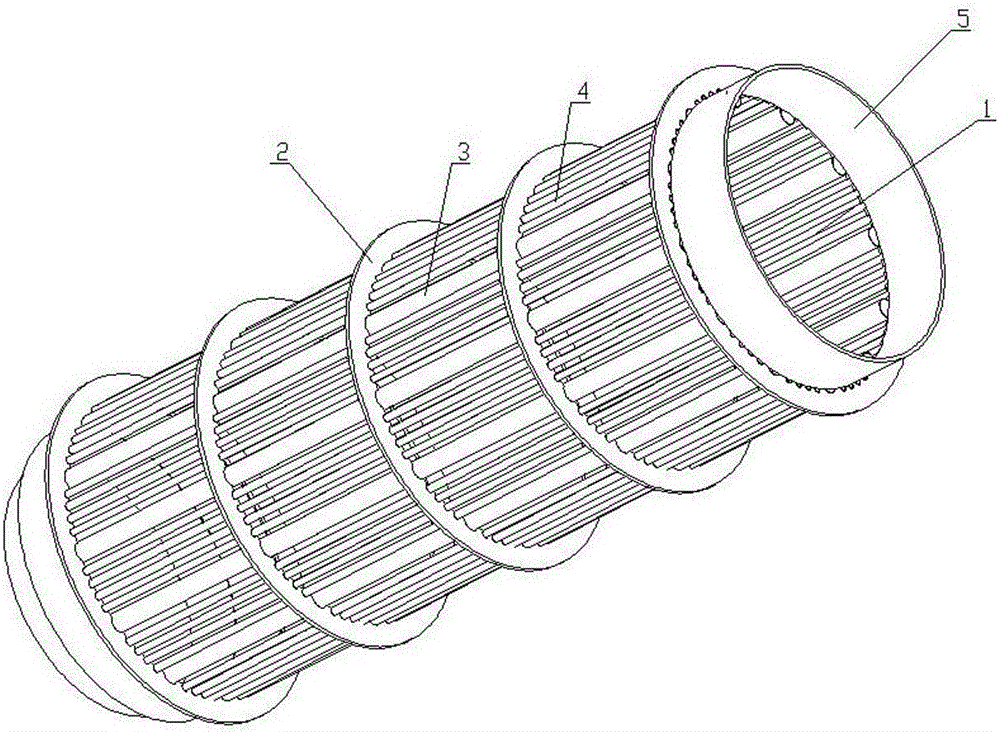

[0015] Such as figure 1 , figure 2 and image 3 As shown, the grid-shaped kneading cylinder for a persimmon kneading machine of the present invention includes a cylinder body 1, and both ends of the cylinder body 1 are open. Both ends of the cylinder 1 are supporting rings 5, and the side wall of the cylinder 1 is composed of no less than four round rods uniformly distributed in the circumferential direction. The axes of the round rods are all parallel to the axis of the cylinder 1, and the Both ends are respectively connected with the corresponding supporting rings 5, and there is a gap between two adjacent circular rods along the circumference of the cylinder body 1, so that the side wall of the cylinder body 1 is in the shape of a grid. The round rods are divided into large round rods 3 and small round rods 4. There are no less than four large round ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com