Method for in-situ repairing of contaminated soil in arsenic slag field

An in-situ remediation and contaminated soil technology, applied in the field of soil pollution remediation of environmental technology, can solve problems such as time-consuming, large-scale engineering, and unsuitable for large-scale site remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

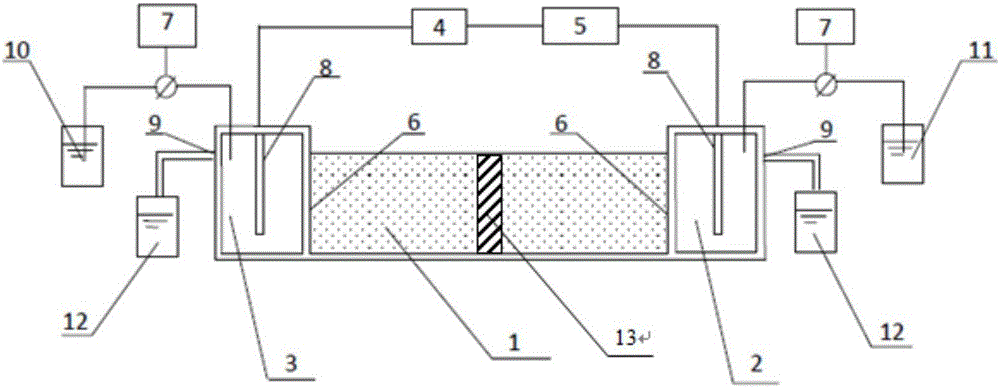

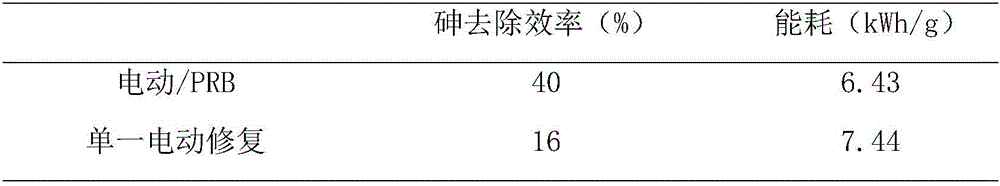

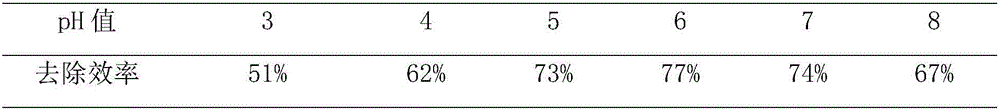

Method used

Image

Examples

Embodiment 1

[0085] A restoration method for removing arsenic in soil in situ, comprising:

[0086] (1) Take the naturally air-dried arsenic-contaminated soil, remove the sundries therein, pulverize it with a pulverizer, pass it through a standard sieve with a particle size of 0.50 mm, and set aside;

[0087] (2) Mix the above-mentioned soil to be used with 2:1 deionized water to make its moisture content 30%, stir it evenly and balance it for one day;

[0088] (3) Take the above-mentioned balanced soil in the soil sample chamber of the electric / PRB joint restoration device, and add 500 mesh filter cloths at both ends of the soil sample to prevent the soil from migrating to the cathode and anode chambers during the restoration process, and fill the cathode and anode chambers with electrolysis solution, the electrolyte uses 0.1mol / L KCl solution, and simultaneously adds a 0.005mol / L enhancement reagent EDTA solution to the cathode chamber.

Embodiment 2

[0093] A restoration method for removing arsenic in soil in situ, comprising:

[0094] (1) Take the naturally air-dried arsenic-contaminated soil, remove the sundries therein, pulverize it with a pulverizer, pass it through a standard sieve with a particle size of 0.50 mm, and set aside;

[0095] (2) Mix the above-mentioned soil to be used with deionized water 1:1 to make the moisture content 25%, stir it evenly and balance it for one day;

[0096] (3) Take the above-mentioned balanced soil in the soil sample chamber of the electric-PRB joint restoration device, and place 400 mesh filter cloths at both ends of the soil sample to prevent the soil from migrating to the cathode and anode chambers during the restoration process, and fill the cathode and anode chambers with electrolysis Liquid, the electrolyte uses 0.05mol / L KCl solution, and simultaneously adds a concentration of 0.001mol / L enhancement reagent EDTA solution to the cathode chamber.

[0097] (4) Insert the graphite...

Embodiment 3

[0101] A restoration method for removing arsenic in soil in situ, comprising:

[0102] (1) Take the naturally air-dried arsenic-contaminated soil, remove the sundries therein, pulverize it with a pulverizer, pass it through a standard sieve with a particle size of 0.50 mm, and set aside;

[0103] (2) Mix the above-mentioned soil to be used with deionized water 3:1 to make the water content of 45%, stir well and balance for one day;

[0104] (3) Take the above-mentioned balanced soil in the soil sample chamber of the electric / PRB combined restoration device, and place 650 mesh filter cloths at both ends of the soil sample to prevent the soil from migrating to the cathode and anode chambers during the restoration process, and fill the cathode and anode chambers with electrolysis Liquid, the electrolyte uses 0.15mol / L KCl solution, and simultaneously adds a concentration of 0.1mol / L enhancement reagent EDTA solution to the cathode chamber.

[0105] (4) Insert the graphite electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com