Control system and method for dynamic load distribution for round billet continuous casting withdrawing-straightening motors

A round billet continuous casting and dynamic distribution technology, which is applied in the round billet continuous casting drawing and leveling motor load dynamic distribution control system and its control field, can solve the adverse effects of crystallizer liquid level fluctuations and process quality requirements, and cast billet surface quality Impact, speed and load mismatch problems, to achieve the effect of convenient disassembly, assembly, maintenance and replacement, ingenious overall structure design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

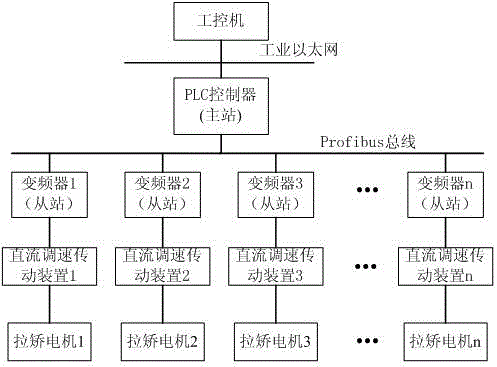

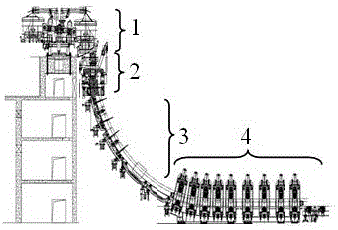

[0038] Such as figure 2 As shown, it is a structural diagram of a full-arc round billet continuous casting machine, which includes ladle turret 1, electromagnetic stirring system 2, wire track 3 and 1#-9# tensioning and straightening motor 4 from top to bottom. The production section is And many other round billets of different specifications belong to the large section round billet continuous casting machine. The drawing and straightening motors are designed to share the load distribution of dummy ingot delivery and billet production with nine racks, and the number of casting strands of the continuous casting machine is designed to be four machines and four streams. Inverters, multiple frequency converters and electrical control components of DC speed-adjusting transmissions) and the console in the main control room can be manually operated, and at the same time, dummy ingot feeding and billet casting can be performed on the monitoring screen of the upper computer (ie indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com