Positioning device for turning of inner hole of copper bush

A positioning device and turning processing technology, applied in positioning devices, auxiliary devices, metal processing equipment, etc., can solve the problems of copper sleeve deformation, inability to directly clamp, outer circle damage, etc., to ensure machining accuracy and reduce production costs. , the effect of improving processing quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

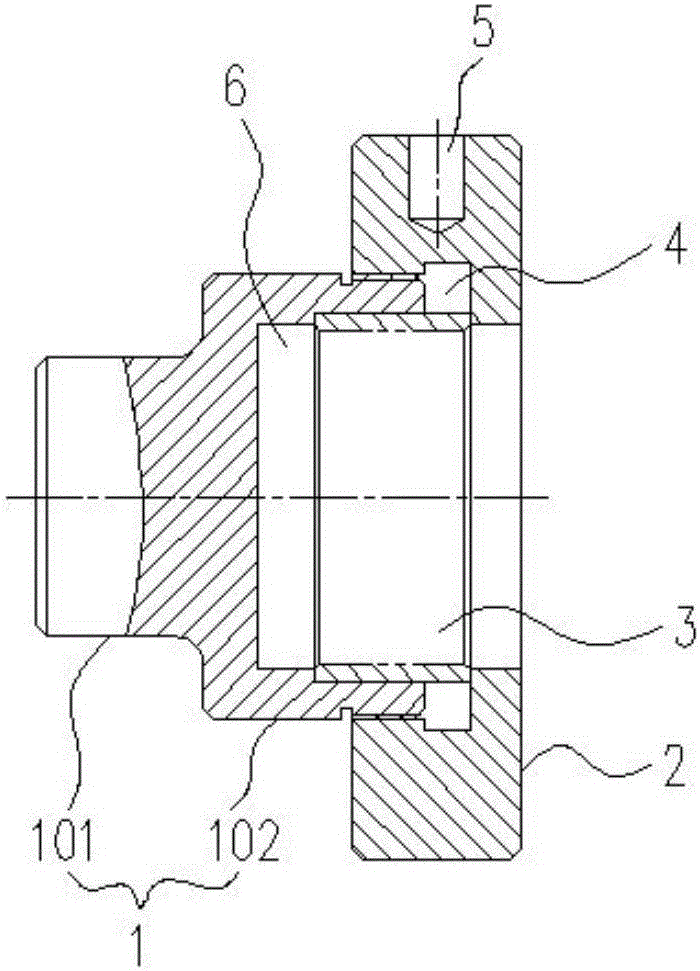

[0011] Such as figure 1 As shown, the structure of this embodiment includes a positioning shaft 1 and a nut 2. One end of the positioning shaft 1 is a copper sleeve positioning end 102, and the other end is a machine tool clamping end 101. The copper sleeve positioning end 102 is provided with a pair of copper sleeves. 3 The stepped hole 6 positioned on the outer circle and the end surface, the outer surface of the positioning end 102 of the copper sleeve is provided with an external thread, the inner hole of the nut 2 is a stepped through hole 4, and the large diameter hole is a threaded hole, which is connected to the positioning end of the copper sleeve. 102 external threads fit, the small diameter hole is larger than the inner diameter of the copper sleeve 3, and smaller than the outer diameter of the copper sleeve 3.

[0012] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com