Automobile back door license plate lamp installation structure

A technology for installation structure and license plate lights, which is applied to doors, signaling devices, and vehicle parts, etc., can solve the problems of difficult stamping and forming in the installation area of license plate lights, affect the integrity of the appearance of the back door, and complex assembly processes, etc., to achieve a simple appearance , Improve production efficiency, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

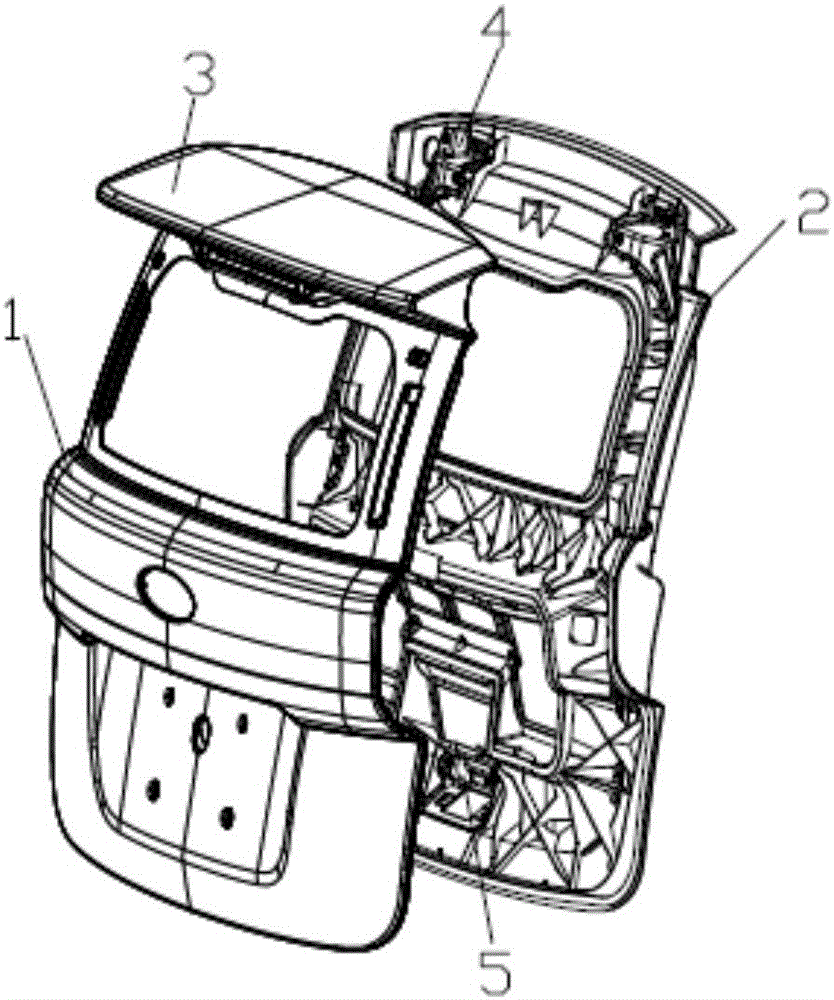

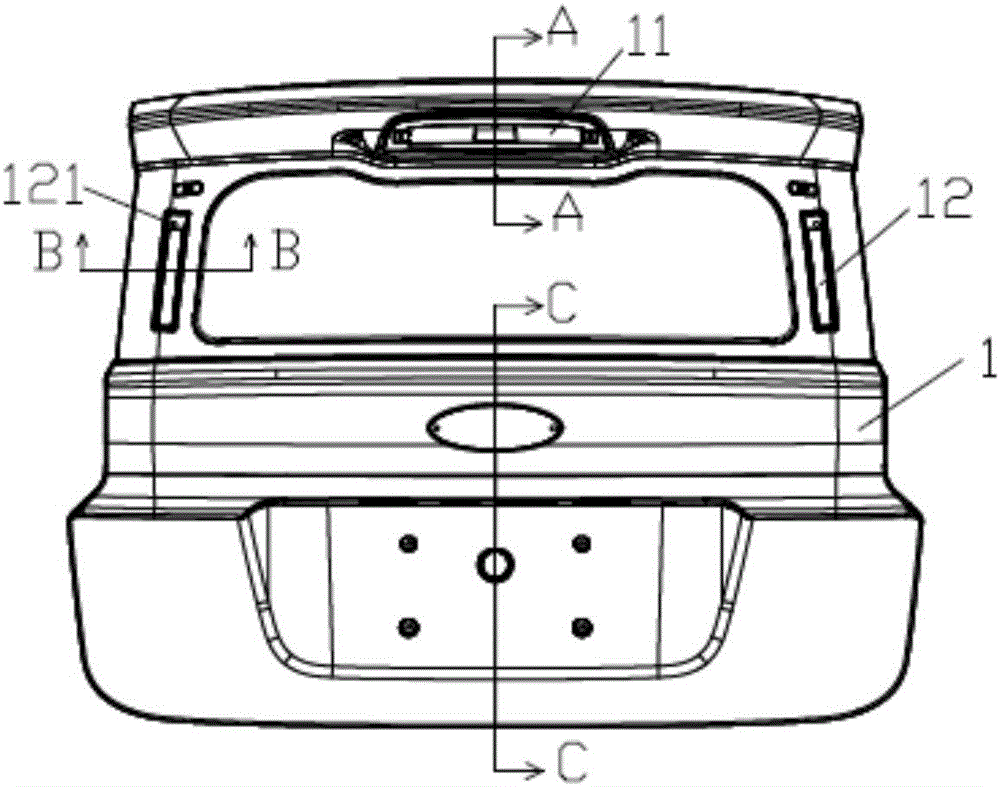

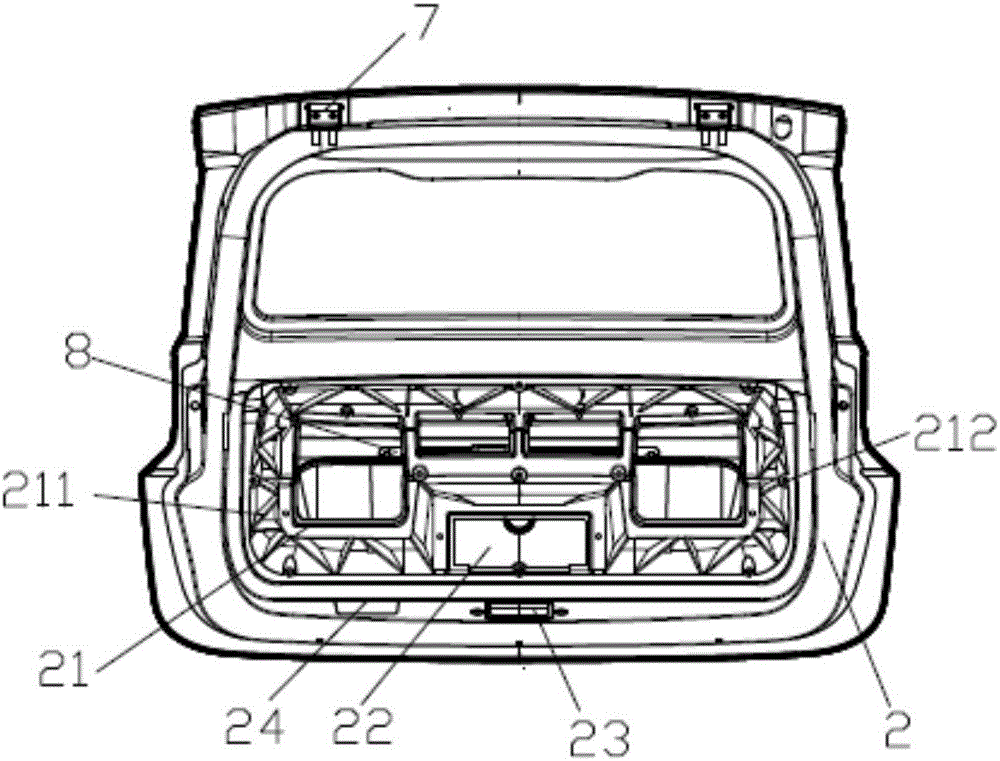

[0051] The installation structure of the car back door license plate light of the present invention, as Figure 28 As shown, it includes a license plate light installation plate 8 located on the inner side of the back door outer panel 1, the back door outer panel 1 is made of PP composite material, the license plate light installation plate 8 is an injection molded part, and the license plate light installation plate 8 and the back The door outer panels are hot-melt connected, and the license plate light mounting plate 8 is provided with a license plate light clamping hole 81 for installing the license plate light.

[0052] A protruding installation platform is provided on the inner side wall of the rear door outer panel 1 above the license plate, and the license plate lamp installation plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com