Conveying belt mechanism capable of achieving both asynchronous running and synchronous transition

A technology of asynchronous operation and conveyor belt, applied in the direction of conveyor, transportation and packaging, can solve the problem of workpiece position error, unable to meet the high requirements of workpiece transfer, difficult to control the synchronous operation of two conveyor belts, etc., to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

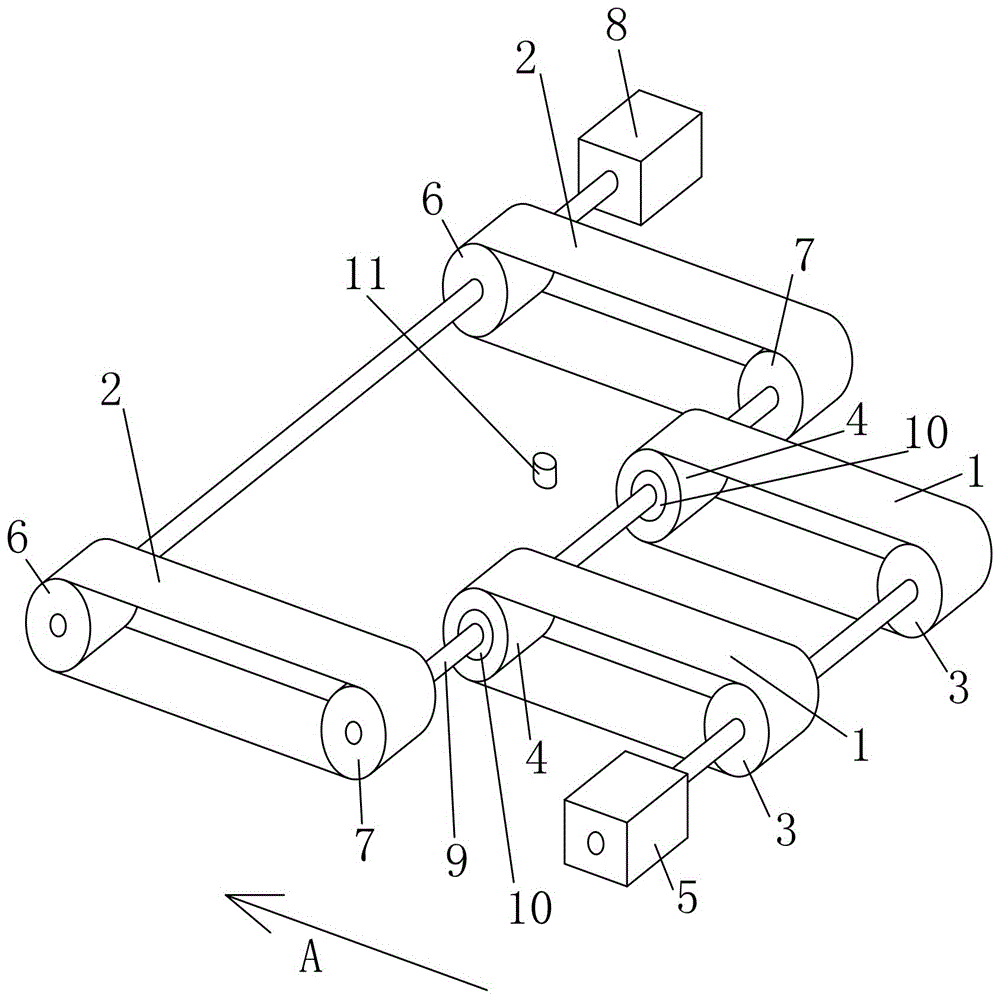

[0009] According to the present invention, a conveyor belt mechanism capable of both asynchronous operation and synchronous transition is provided, such as figure 1 As shown, there are two sections of conveyor belts 1, 2, based on the workpiece conveying direction shown by arrow A, the two conveyor belts 1, 2 are respectively located upstream and downstream of the workpiece conveying direction. The upstream conveyor belt 1 is connected with the driving pulley 3 and the passive pulley 4, the driving pulley 3 is connected with the prime mover 5, the prime mover 5 drives the driving pulley 3 to rotate, and the driving pulley 3 drives the upstream conveyor belt 1 toward the arrow A Transport the workpiece in the indicated direction. The downstream conveyor belt 2 is connected to the driving pulley 6 and the passive pulley 7, and the driving pulley 6 is connected to another prime mover 8. The prime mover 8 drives the driving pulley 6 to rotate, and then the driving pulley 6 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com