Glassine double-faced hot melting adhesive tape and preparation method thereof

A technology of glassine paper and hot-melt tape, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve problems such as unstable release, wrinkled coating, and wrinkled glue surfaces. Achieve the effect of reducing the risk of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of glassine paper double-sided hot-melt adhesive tape of the present invention comprises the steps:

[0023] S1. Provide a glassine paper, through different release ratios, the two sides of the glassine paper are released differently to form a glassine release paper, and the glassine release paper has the characteristics formed by the release ratio The heavy release surface and the light release surface; in a specific embodiment, the release force ratio of the heavy release surface and the light release surface is greater than or equal to 1:1.5 and not more than 1:5. In addition, the glassine The paper adopts silicone oil release agent;

[0024] S2. Provide a base material, which can be gauze, PET film, PP film, etc.; apply the hot melt glue on the heavy release surface of the glassine release paper formed in step S1 by extrusion, and Composite the glassine release paper with the base material through the composite equipment, and transfer the hot...

Embodiment 1

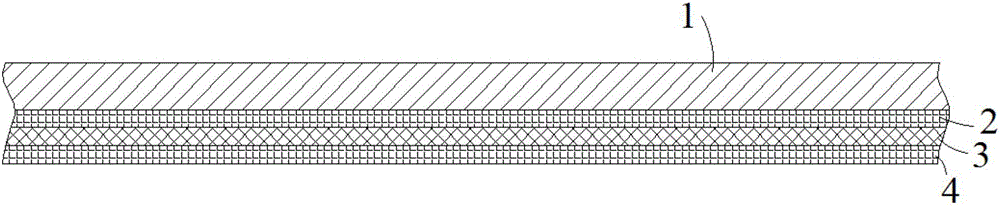

[0031] Glassine paper double-sided hot-melt adhesive tape includes glassine release paper, first adhesive layer, substrate and second adhesive layer from one surface to the other opposite surface in sequence, the heavy release surface of glassine release paper and The release force ratio of the light release surface is 1:1.5; the percentages of each component of the first adhesive layer and the second adhesive layer are: thermoplastic elastomer 25%, softening oil 20%, resin 40%, antioxidant 1 %, filler 14%.

[0032] The preparation method of above-mentioned glassine paper double-sided hot-melt adhesive tape comprises the steps:

[0033] S1. Provide a glassine paper, through different release ratios, the two sides of the glassine paper are released differently to form a glassine release paper, and the glassine release paper has the characteristics formed by the release ratio The heavy release surface and light release surface, the release force ratio of the heavy release surfa...

Embodiment 2

[0038]Glassine paper double-sided hot-melt adhesive tape includes glassine release paper, first adhesive layer, substrate and second adhesive layer from one surface to the other opposite surface in sequence, the heavy release surface of glassine release paper and The release force ratio of the light release surface is 1:2; the percentages of the components of the first adhesive layer are: thermoplastic elastomer 30%, softening oil 13.5%, resin 40%, antioxidant 1.5%, filler 15% %, the percentages of the components of the second adhesive layer are: thermoplastic elastomer 25%, softening oil 20%, resin 49.5%, antioxidant 0.5%, filler 5%.

[0039] The preparation method of above-mentioned glassine paper double-sided hot-melt adhesive tape comprises the steps:

[0040] S1. Provide a glassine paper, through different release ratios, the two sides of the glassine paper are released differently to form a glassine release paper, and the glassine release paper has the characteristics fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com