A kind of production method of indentation translucent artistic anti-counterfeiting paper

A production method and translucent technology, which are applied in pulp beating method, paper making, patterned paper, etc., can solve the problems of low precision of watermark pattern and limited precision of watermark pattern, and achieve reliable production process, easy processing and good anti-counterfeiting performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

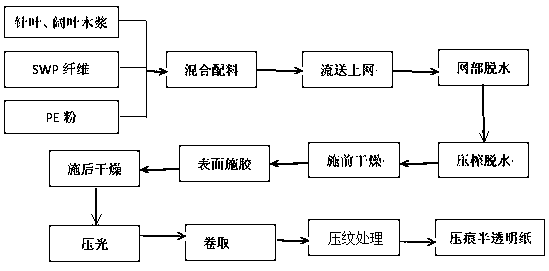

Method used

Image

Examples

Embodiment 1

[0020] Example 1 120g / m 2 Production of anti-counterfeiting translucent art paper with indentation of Li Baidou wine picture.

[0021] (1) Selection and treatment of raw materials Coniferous wood pulp, hardwood pulp, SWP fiber, and PE powder are selected as raw materials. The absolute dry weight of softwood pulp in raw materials is 20%, hardwood pulp is 20%, and SWP fiber is 40%. PE powder is 20%. Specifically, 600kg of coniferous and broadleaf mixed pulp, 600kg of SWP fiber, and 300kg of PE powder. The coniferous wood pulp and hardwood pulp are put into the hydraulic pulper at a ratio of 1:1 for crushing. After crushing, the pulp is beaten by a large taper beater. The beating concentration is 6.0%, and the beating degree is 30. o Sr. Put the SWP fiber into the trough beater, the beating concentration is 3.0%, beating in the first 60 minutes by light to loosening method, and the fiber is cut and beating by the heavy knife in the last 60 minutes, the total beating time is 12...

Embodiment 2

[0025] Example 2 110g / m 2 Production of translucent slub paper.

[0026] (1) Selection and treatment of raw materials Coniferous wood pulp, hardwood pulp, SWP fiber, and PE powder are selected as raw materials. The absolute dry weight of softwood pulp in raw materials is 10%, hardwood pulp is 10%, and SWP fiber is 70%. PE powder is 10%. Specifically, 300kg of coniferous and broadleaf mixed pulp, 1050kg of SWP fiber, and 150kg of PE powder. The coniferous wood pulp and hardwood pulp are put into the hydraulic pulper at a ratio of 1:1 for crushing. After crushing, the pulp is beaten by a large taper beater. The beating concentration is 6.0%, and the beating degree is 30. oSr. Put the SWP fiber into the trough beater, the beating concentration is 3.0%, beating in the first 60 minutes by light to loosening method, and the fiber is cut and beating by the heavy knife in the last 60 minutes, the total beating time is 120 minutes.

[0027] (2) Mixing ingredients Add the coniferous...

Embodiment 3

[0030] Example 3 140g / m 2 Production of translucent bamboo denim paper.

[0031] (1) Selection and treatment of raw materials Softwood pulp, hardwood pulp, and SWP fiber are selected as raw materials. The absolute dry weight of softwood pulp in raw materials is 20%, hardwood pulp is 20%, and SWP fiber is 60%. Specifically, 600kg of coniferous and broadleaf mixed pulp and 900kg of SWP fiber. The coniferous wood pulp and hardwood pulp are put into the hydraulic pulper at a ratio of 1:1 for crushing. After crushing, the pulp is beaten by a large taper beater. The beating concentration is 6.0%, and the beating degree is 30. o Sr. Put the SWP fiber into the trough beater, the beating concentration is 3.0%, beating in the first 60 minutes by light to loosening method, and the fiber is cut and beating by the heavy knife in the last 60 minutes, the total beating time is 120 minutes.

[0032] (2) Mixing ingredients Add the beaten coniferous and broad-leaved mixed pulp and dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com