Coordinate transfer method for shaft excavation construction

A technology of shafts and coordinates, which is used in measuring devices, instruments, surveying and mapping, and navigation, etc., can solve problems such as the inability to solve the problems of accurate steering in the downward bending plane of the shaft, the wire is easily broken, and the safety risk is high, so as to improve the construction efficiency and improve the safety. Construction efficiency, the effect of simplifying construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

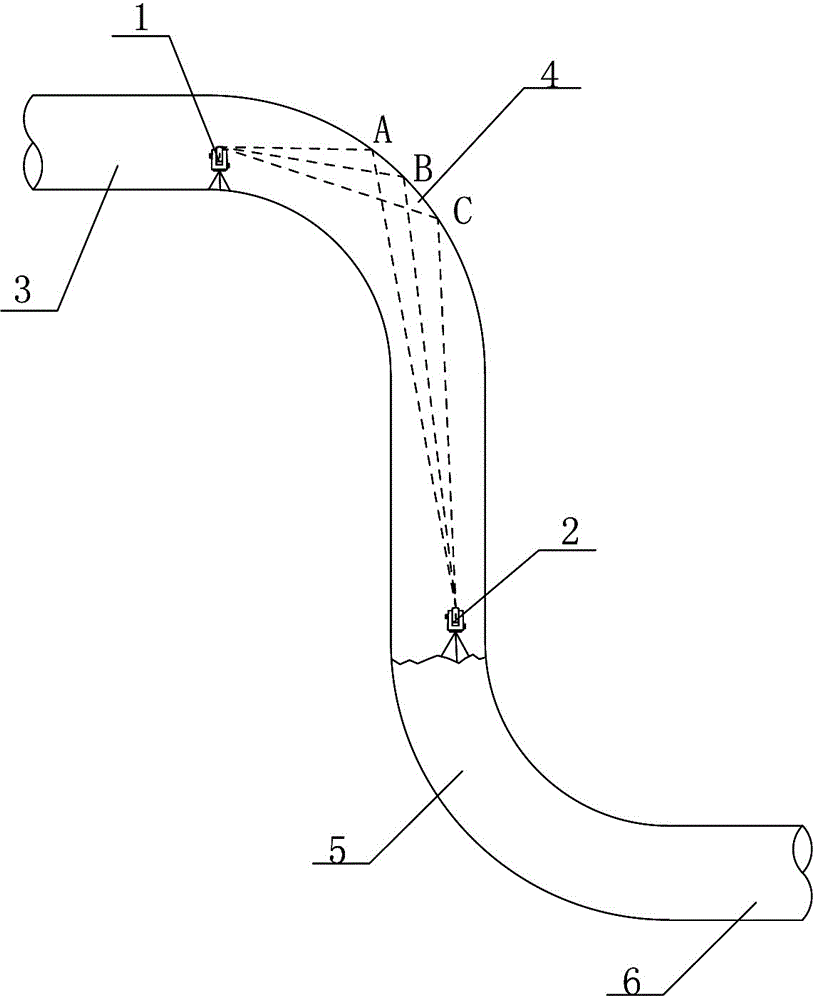

[0019] A coordinate transfer method for shaft excavation construction, comprising a first total station 1 and a second total station 2, the first total station 1 is set up on the upper flat section 3 of the shaft, and the second total station is set up at the bottom of the shaft The station instrument 2 detects the coordinates of the laser point projected on the upper curve section 4 through the first total station instrument 1, and sets the second total station instrument 2 to realize coordinate transfer.

Embodiment 2

[0021] On the basis of embodiment 1, comprise the following steps:

[0022] 1) Set up the first total station 1 and the second total station 2 on the upper flat section 3 and the bottom of the shaft respectively;

[0023] 2) Use the second total station 2 at the bottom of the shaft to project the laser on the point A on the upward curved section 4, and then use the first total station 1 installed on the upper flat section 3 to project the laser, so that the first total station 1 The laser is projected on point A, and the coordinate value of point A is obtained;

[0024] 3) Use the second total station 2 at the bottom of the shaft to project the laser on the point B on the upward curved section 4, and then use the first total station 1 installed on the upper flat section 3 to project the laser, so that the first total station 1 The laser is projected on point B, and the coordinate value of point B is obtained;

[0025] 4) According to the coordinates of the two points in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com