A microbolometer with high filling factor and its preparation method

A microbolometer and fill factor technology, applied in the direction of electric radiation detectors, can solve the problems of increased process difficulty, uneven deposition, excessive diameter, etc., to increase the difficulty of process, simple manufacturing process, occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand a microbolometer with a high filling factor of the present invention and its preparation method, the following examples are listed and described in detail with accompanying drawings. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but to illustrate the essence of the technical solution of the present invention.

[0037] Its specific process steps:

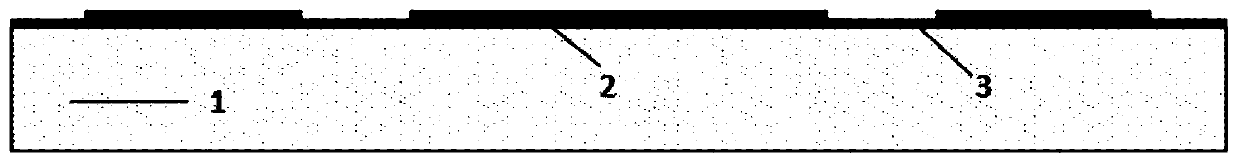

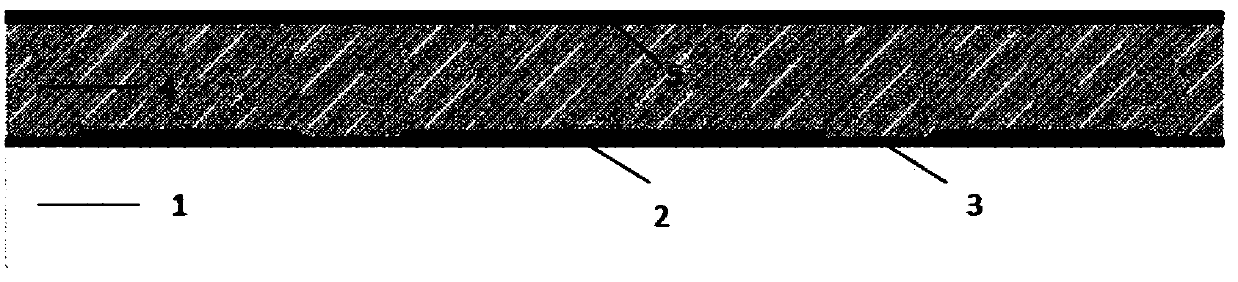

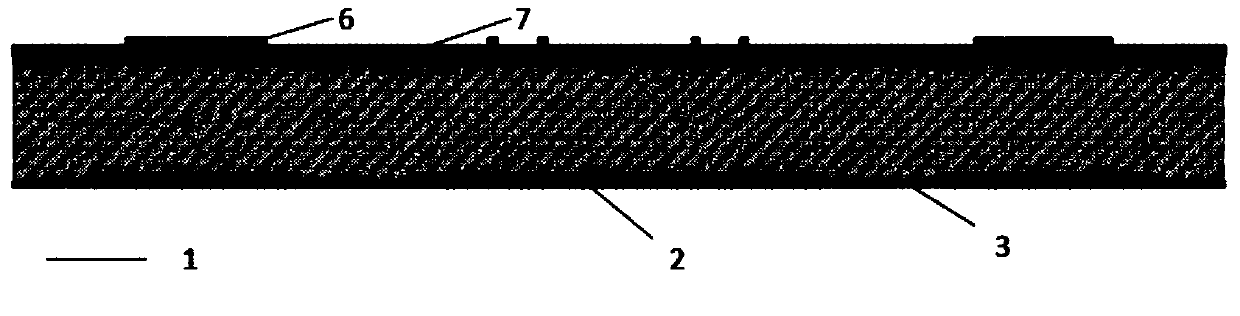

[0038]The metal reflective layer 2 is fabricated on the wafer with the processed readout circuit 1 as the base, the thickness of the film is 0.05-0.40 μm, and the metal reflective layer can be selected from Au, Cu, and Al. After etching the metal reflective layer 2, deposit a layer of silicon nitride film with a thickness of 0.02-0.30 μm on the reflective layer pattern as the insulating dielectric layer 3, such as figure 1 shown.

[0039] Preparation of the sacrificial layer 4, the sacrificial layer 4 can be mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com