Stereoscopic solar cell module production flow line

A technology for solar cells and production lines, applied to electrical components, semiconductor devices, circuits, etc., can solve the problems of large footprint and waste of space, and achieve the effects of high space utilization, compact and complete structure, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

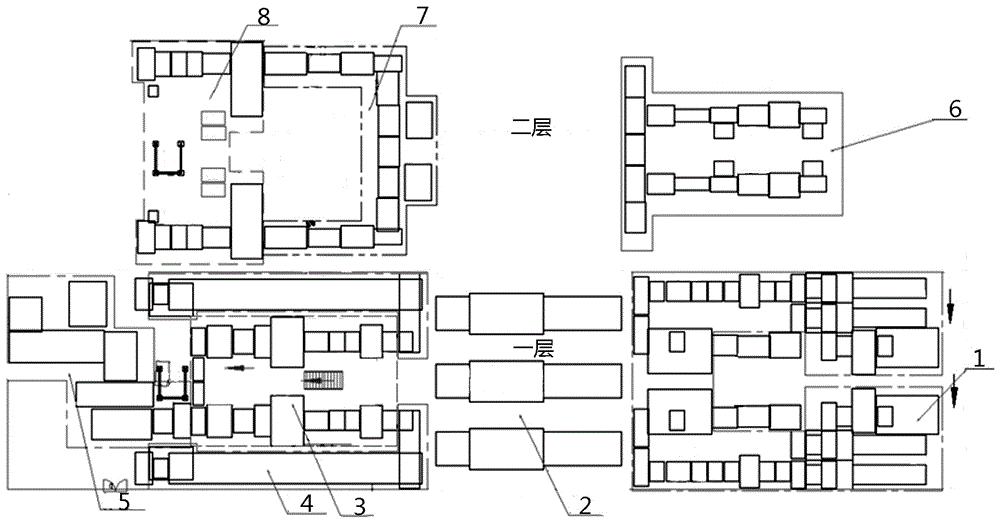

[0017] See figure 1 A vertical solar cell module production line shown, including welding laying area 1, pre-lamination inspection area 6, lamination area 2, post-lamination inspection area 7, frame area 8, curing area 4, cleaning test area 3 and 5 eight parts of the automatic packing area. In the present invention, the whole set of equipment is arranged in the three-dimensional space from the first floor to the second floor according to the technological process. In the present invention, a welding laying area 1 , a lamination area 2 , a cleaning test area 3 , a curing area 4 and an automatic packing area 5 are arranged on the first floor. A pre-lamination detection area 6 , a post-lamination detection area 7 and a group frame area 8 are arranged on the two-layer frame. A lifting transmission unit is provided between the relevant equipment on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com