Intermediate current mode dual-tube forward micro-inverter and its digital control device

A dual-tube forward excitation, micro-inverter technology, applied in the direction of adjusting electrical variables, control/regulating systems, output power conversion devices, etc., can solve the problem that boost converters are difficult to achieve high boost ratio, efficiency is difficult, and high efficiency and other problems to achieve the effect of eliminating reverse recovery loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

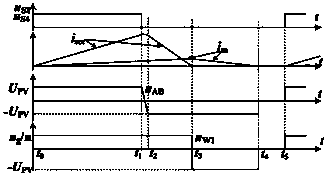

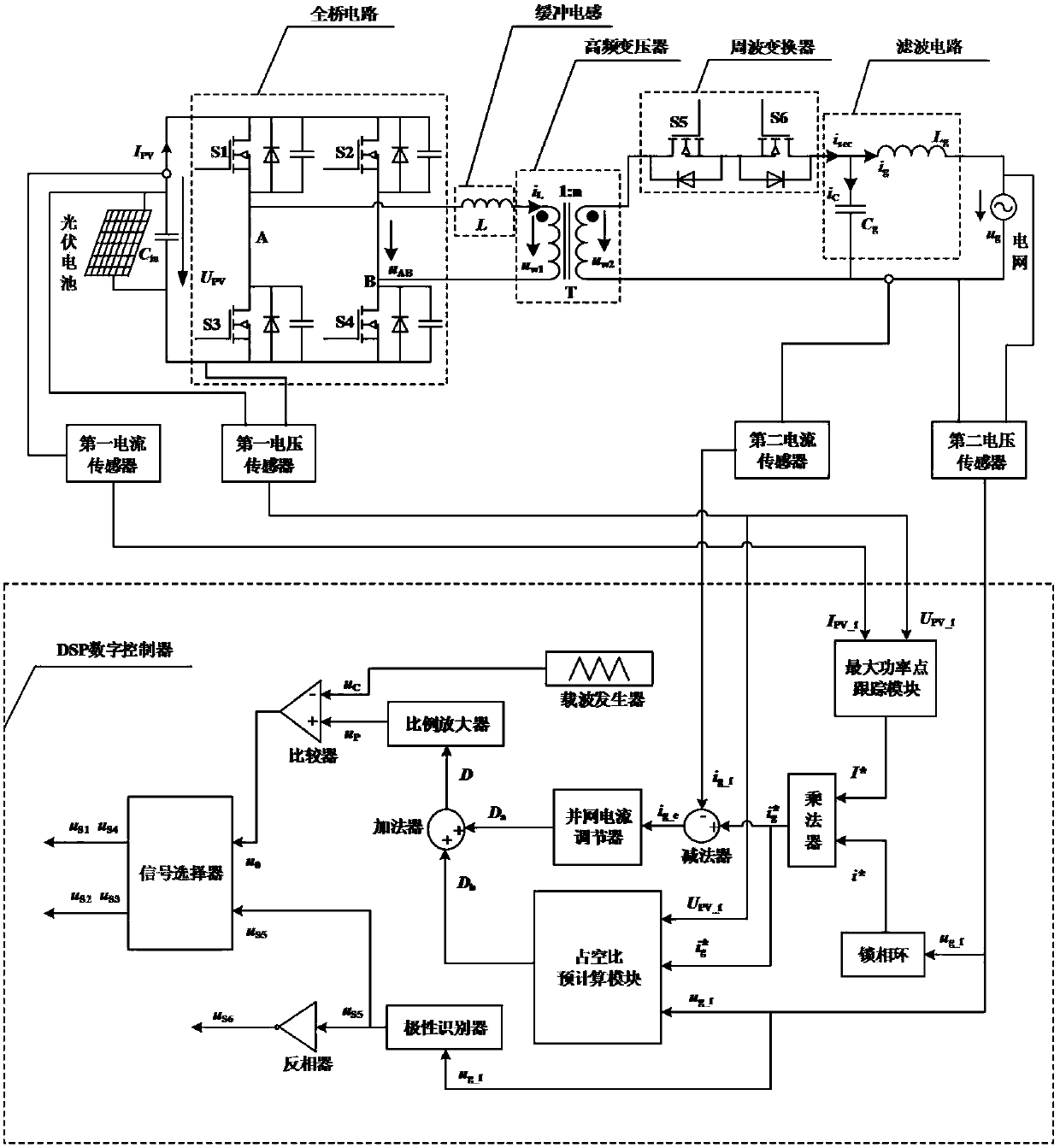

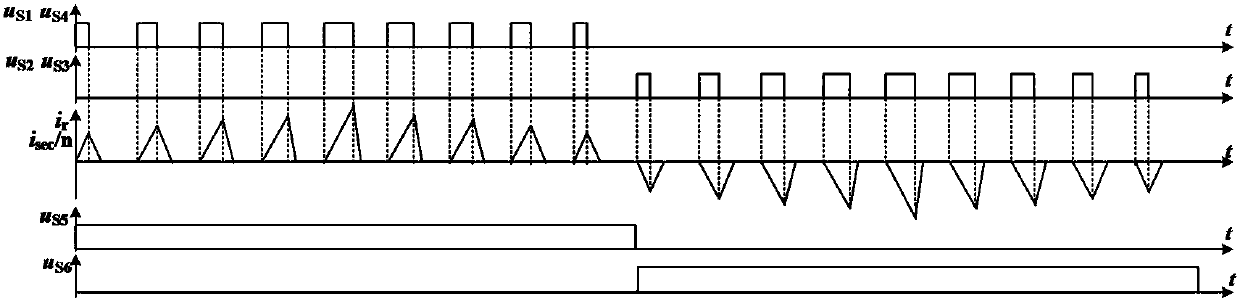

[0032] Such as figure 1 As shown, the middle current type dual-tube forward micro-inverter, including the input filter capacitor C in , full-bridge circuit, snubber inductor L, high-frequency transformer T, cycloconverter and LC grid-connected filter circuit, the following will describe their interconnection and components in detail.

[0033] The full bridge circuit uses photovoltaic cells as the input power supply, and includes the first switching tube S1, the second switching tube S2, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com