Clutch system with dual clutch and CSC with an axial CSC bearing comprising a platform for receiving the CSC, and powertrain

A power train and clutch technology, applied in the field of clutch systems, can solve problems such as separate structural space and achieve the effect of saving axial structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

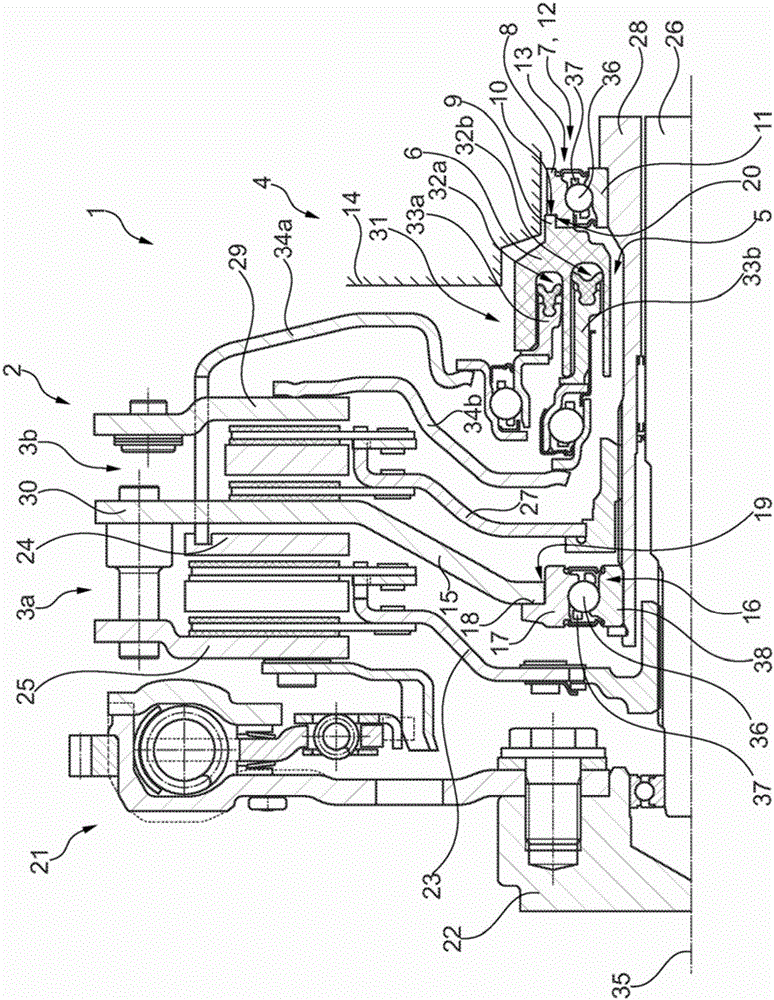

[0026] only figure 1 An advantageous embodiment of the clutch system 1 according to the invention is shown. In this figure, the clutch system 1 is shown already in a state in which the clutch system is integrated into the drive train of a motor vehicle. The clutch system 1 here includes a clutch 2 which is designed as a double clutch. Here, the clutch 2 is connected on the input side in a rotationally fixed manner to an output shaft 22 / crankshaft of an internal combustion engine, for example an Otto or Diesel engine, by means of a damping device 21 , which is designed here as a dual-mass flywheel. According to the design of the double clutch, the clutch 2 has two clutch parts / subclutches 3a and 3b, wherein the first clutch part is provided with the reference numeral 3a and the other second subclutch or another second clutch part is provided with the reference numeral 3b.

[0027] Each partial clutch / clutch part 3a and 3b is in turn designed as a dry friction clutch / frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com