Limestone-gypsum process desulphurization apparatus

A desulfurization device, limestone technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low desulfurization efficiency, difficulty in reaching emission targets for sulfur dioxide, incomplete desulfurization, etc. Longevity and effect of improving anticorrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

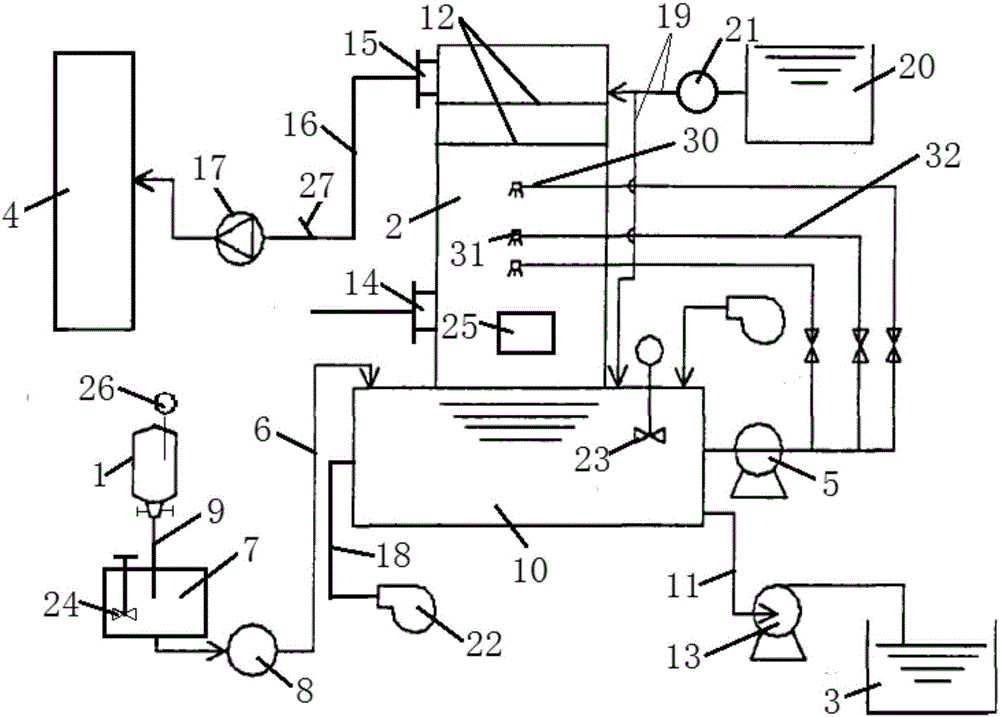

[0018] refer to figure 1 , the limestone gypsum desulfurization device includes a limestone silo 1, a desulfurization tower 2, a gypsum settling tank 3 and a chimney 4, the inner bottom of the desulfurization tower 2 is a desulfurization tank 10, and the top of the desulfurization tower 2 is provided with two layers of The mist eliminator 12, below the mist eliminator 12 is a longitudinally arranged three-layer spray layer 30, the spray layer 30 includes a nozzle 31 and a spray pipe 32, the nozzle 31 is connected to the desulfurization tank 10 through the spray pipe 32, and the spray The pipe 32 is provided with a circulating pump 5 at one end near the desulfurization tank 10. The top of the desulfurization tank 10 is connected to the slurry tank 7 through the slurry feeding pipe 6. The slurry feeding pipe 6 is provided with a slurry feeding pump 8, and the slurry tank 7 is communicated through the powder feeding pipe 9. The limestone silo 10 above it, the bottom of the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com