Method of manufacturing magnetic soft material

A soft magnetic material and working technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of inability to mass-produce or form large-scale or complex shapes, poor electromagnetic conversion rate, etc. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order for Ligui examiners to understand the technical features, content and advantages of the present invention and the effects it can achieve, the present invention is hereby combined with the accompanying drawings and described in detail in the form of embodiments as follows, and the drawings used therein, Its purpose is only for illustration and auxiliary instructions, not necessarily the true proportion and precise configuration of the present invention after implementation, so it should not be interpreted based on the proportion and configuration relationship of the attached drawings, and limit the scope of rights of the present invention in actual implementation , together first describe.

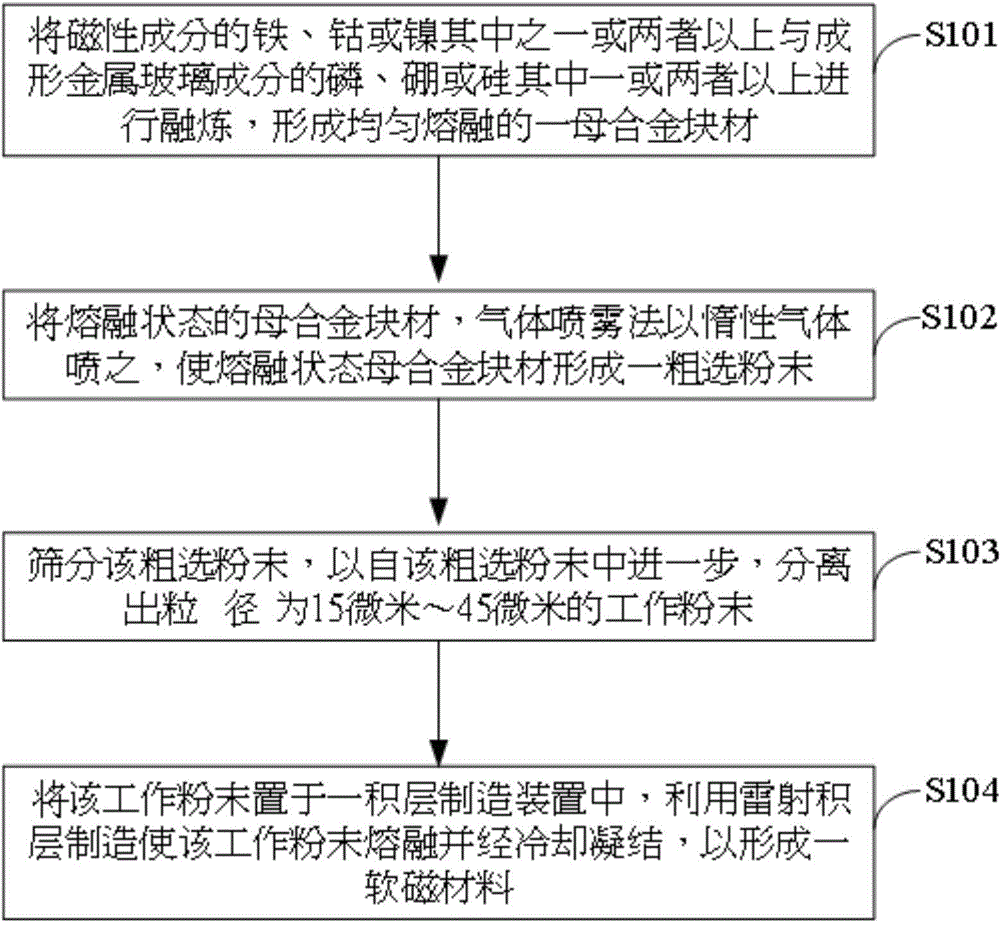

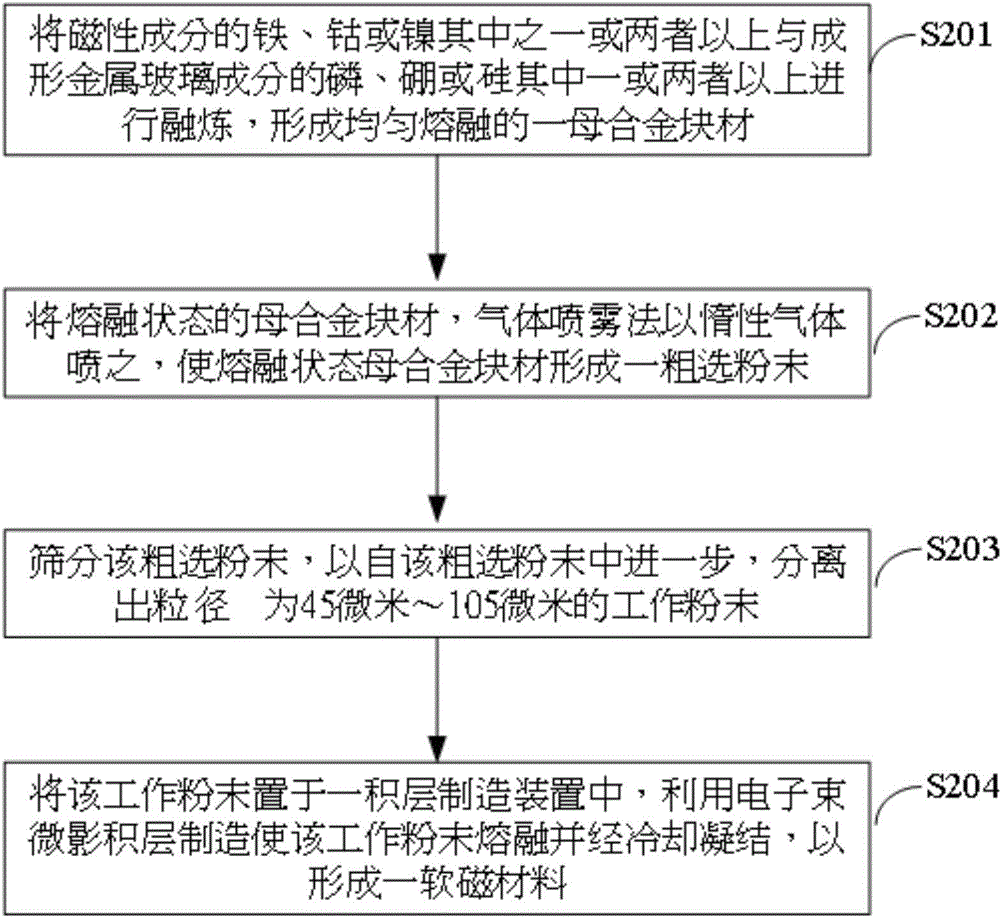

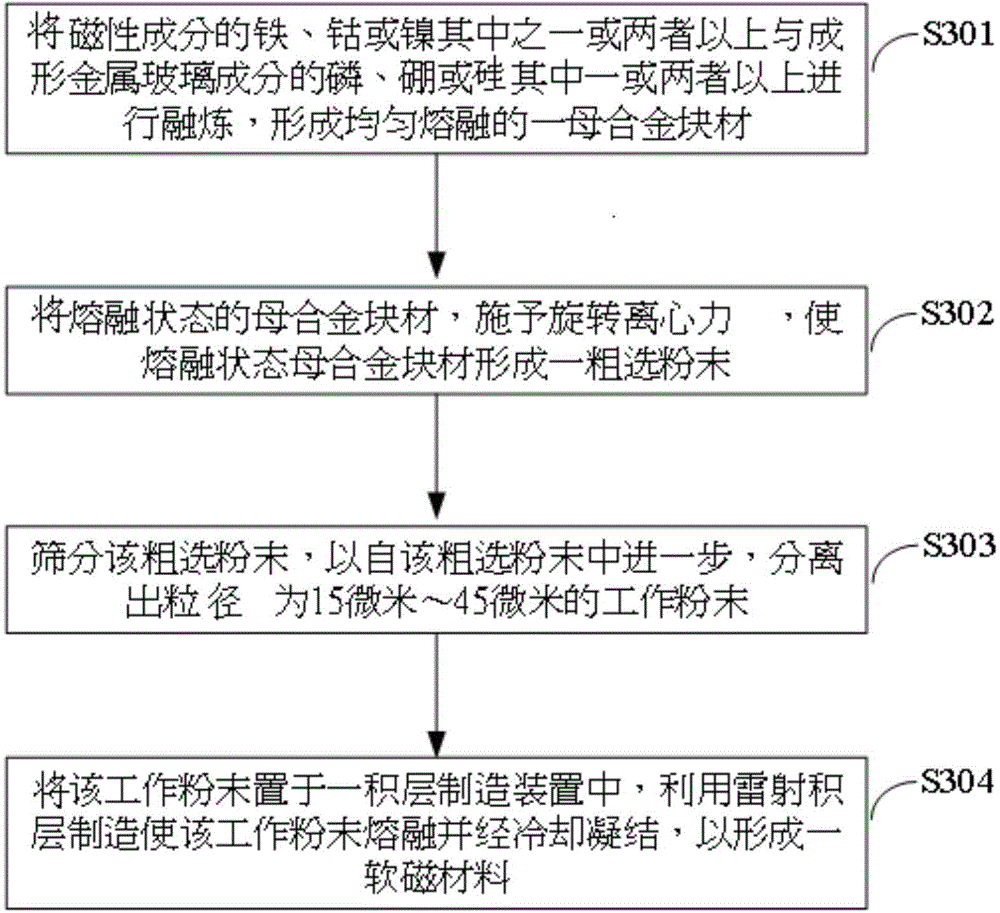

[0021] The method for producing soft magnetic material of the present invention can be formed at one time to replace the traditional iron core material. The method for producing soft magnetic material includes: melting the magnetic component and the component of the formed me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com