Gravity pressurization and automatic mechanical pressurization integrated grinding and polishing machine

A technology of automatic machinery and polishing machines, which is applied in the direction of grinding machine tools, grinding/polishing equipment, grinding devices, etc., and can solve problems such as low yield, low grinding and polishing efficiency, and inability to accurately control grinding and polishing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

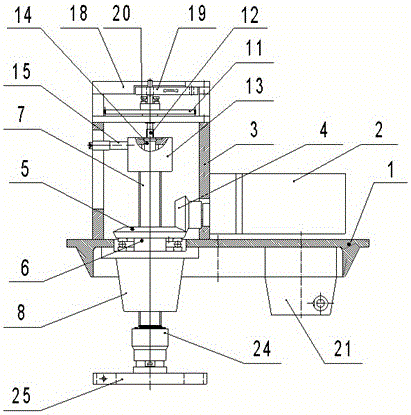

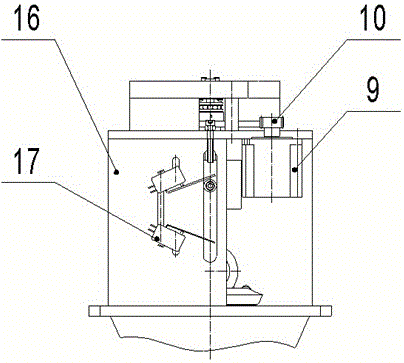

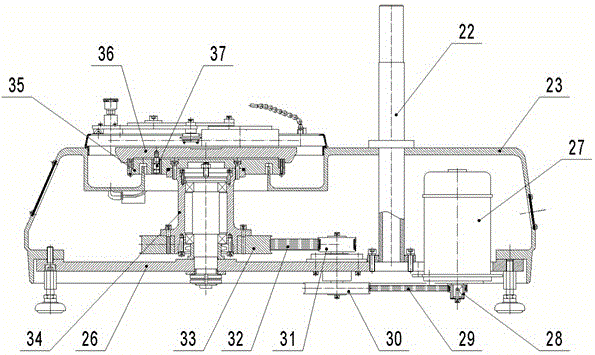

[0017] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0018] As shown in the figure, a grinding and polishing machine integrated with gravity pressurization and automatic mechanical pressurization in the present invention includes: an upper spindle transmission mechanism: a power motor 2 is installed on the bottom support plate 1 through a power motor fixing plate 3, and the output end of the motor is actively The bevel gear 4 meshes with the driven bevel gear 5 at an angle of 90°, the driven bevel gear 5 is fixed with the inner spline shaft 6, the outer spline shaft 7 is sleeved inside the inner spline shaft 6, and the inner spline shaft 6 passes through the main shaft seat 8 is fixed on the bottom supporting plate 1.

[0019] Pressurized transmission mechanism: the output end of the pressurized motor 9 is connected to the driving cylindrical gear 10, the driving cylindrical gear 10 meshes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com