Recycling regeneration method and device for adsorbent for drying compressed air in power plant

A technology of compressed air and dry adsorption, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of long regeneration time, high loss rate of adsorbent, short service life of desiccant, etc., to ensure stability and The effect of continuity, avoiding waste of manpower and materials, and small footprint of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

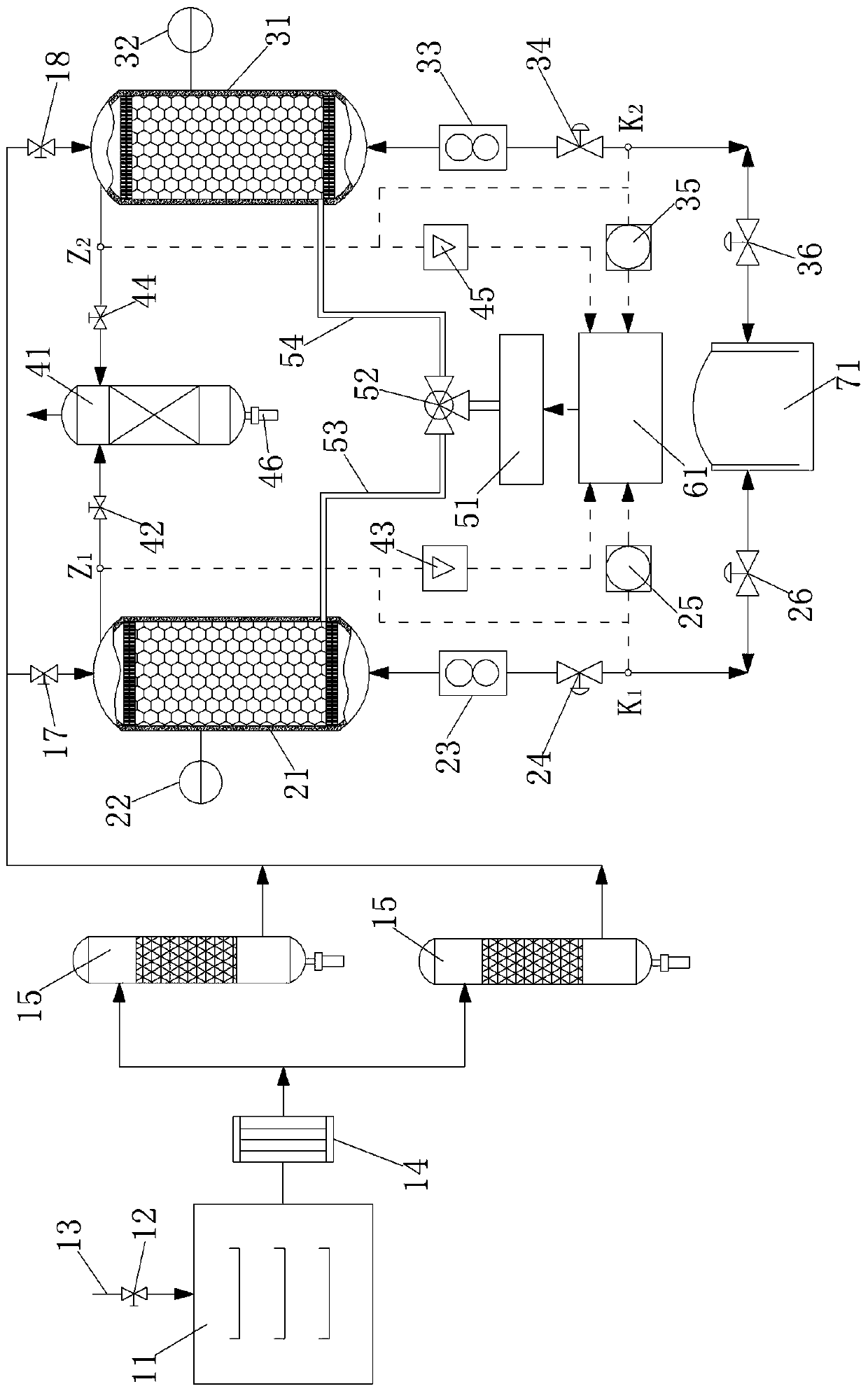

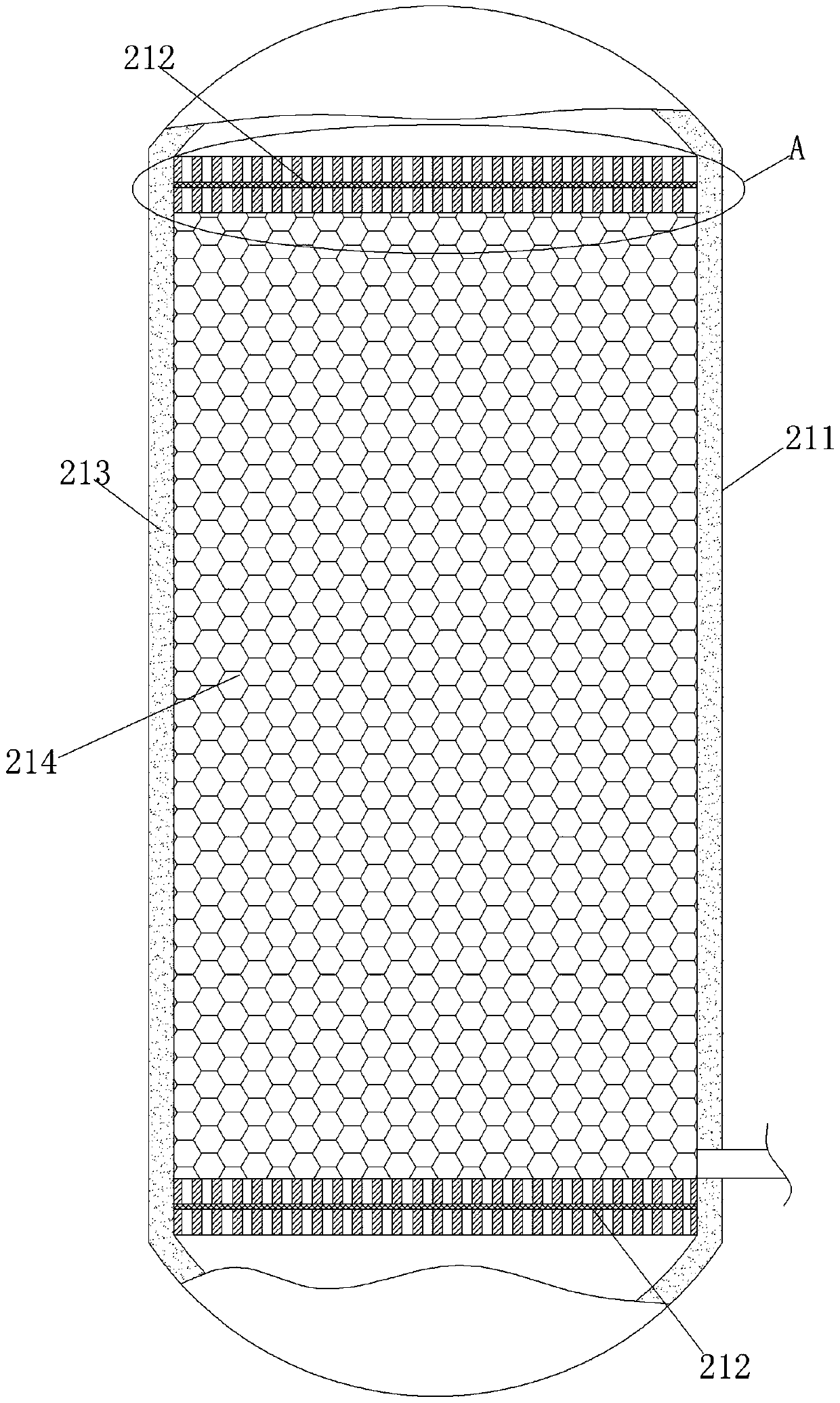

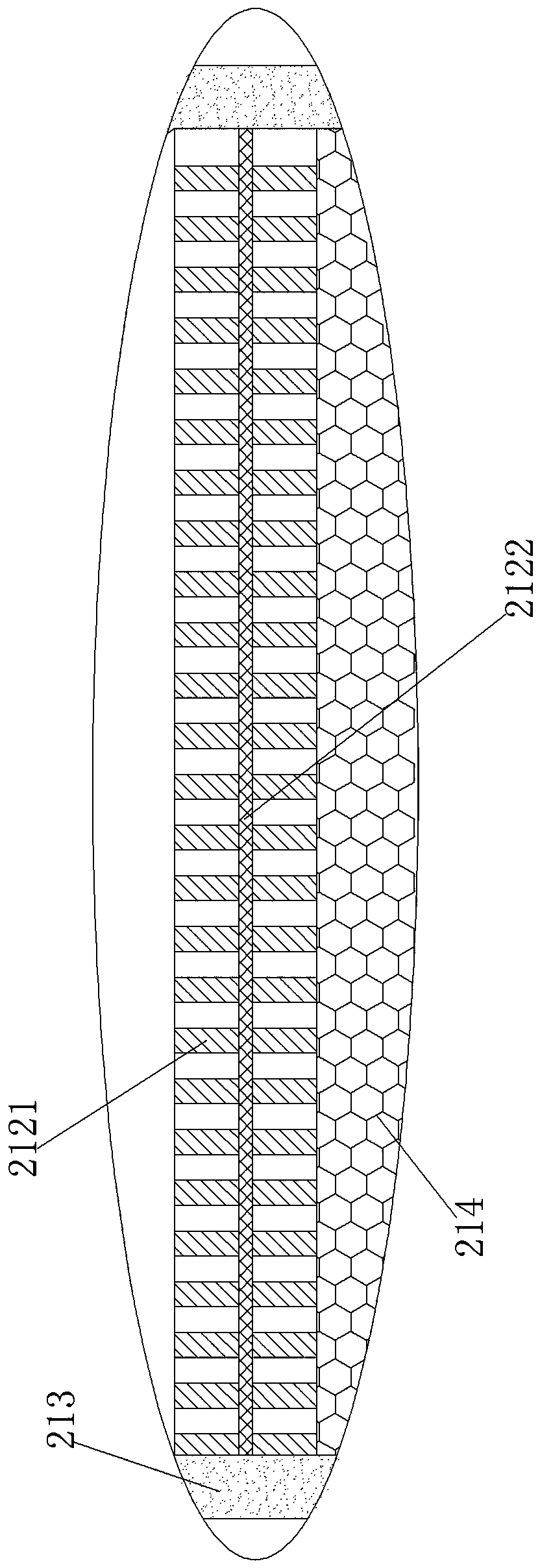

[0031] Embodiment one, see Figure 1-3 , a method and device for cyclic regeneration of compressed air drying adsorbents in power plants, the device includes an air compressor, a precooler, a dust and oil filter, an adsorption tower, a steam-water separator, a microwave generator, a PLC controller and The gas storage tank, the adsorption tower includes adsorption tower A and adsorption tower B,

[0032] The air compressor is provided with a main air intake pipe, and an air source main valve is connected in series on the main air intake pipe. The air compressor communicates with the pre-cooler through the air duct, and the pre-cooler is respectively connected with two dust and oil removal units through the air duct. The filter is connected, and the two dust and oil removal filters are connected to the upper ends of the adsorption tower A and the adsorption tower B through the air conduit. The air conduit connected to the upper end of the adsorption tower A is connected in serie...

Embodiment 2

[0041] Embodiment two, see Figure 1-3 , a kind of method for the cycle regeneration device of compressed air drying adsorbent described in application embodiment one, the method comprises the following steps:

[0042] ① Check the tightness of the gas circuit of the entire device. When the air compressor starts to start, open each valve and flow meter in turn to monitor the changes in the working pressure and gas flow of adsorption tower A and adsorption tower B.

[0043] ② When the main valve of the air source is opened, the ambient atmosphere shall be as follows: figure 1 The air compressor is sucked into the air compressor in the direction of the arrow shown, and the working cycle of suction-compression-exhaust starts. The hot compressed air (exhaust pressure is 0.7-0.8MPa) from the air compressor exhaust port first passes through the pre-cooler. After cooling down, it enters the dust and oil removal filter to remove impurities such as oil and dust particles carried by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com