DC motor brush position calibration device

A DC motor, brush position technology, applied in the direction of using electric devices, electromagnetic measuring devices, electric/magnetic position measurement, etc., can solve the problems of time-consuming brush position adjustment, discontinuous signal, poor safety, etc., to achieve structural Simple, continuous and stable signal, fast calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

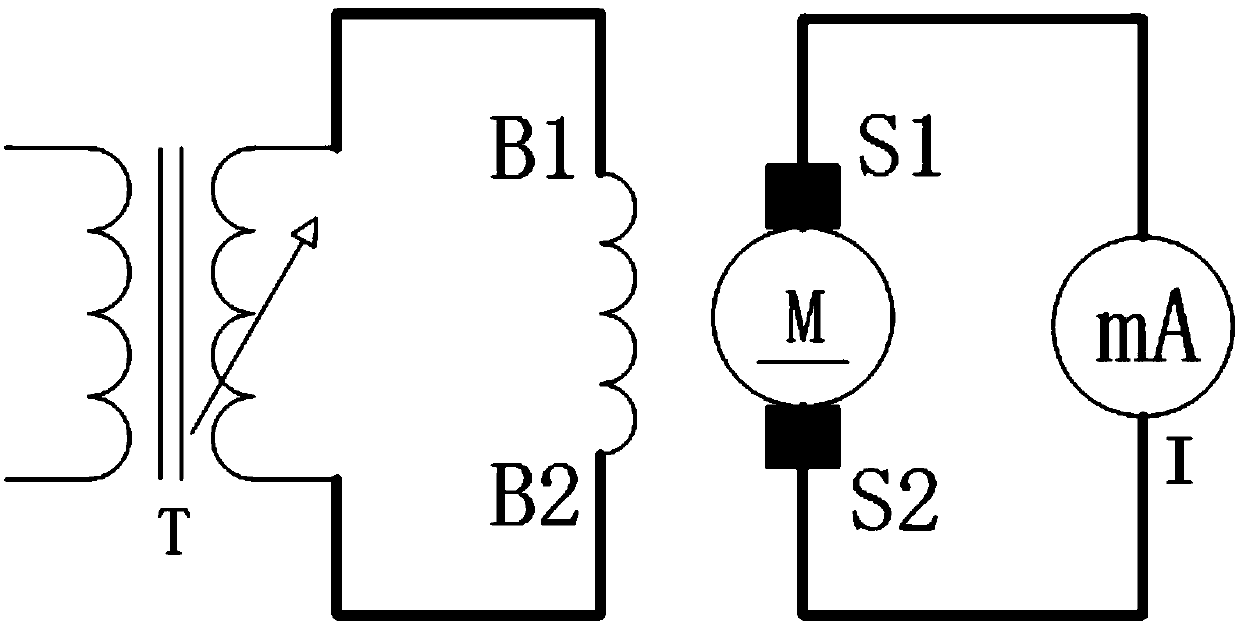

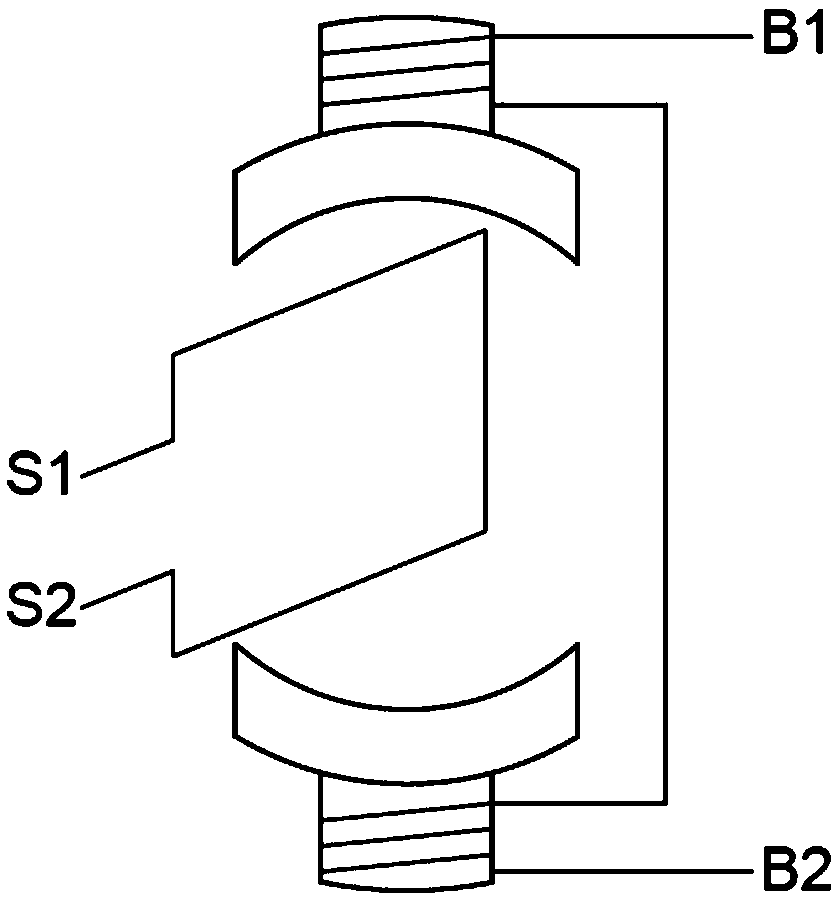

[0018] see figure 1 with figure 2 As shown, a DC motor brush position calibration device of the present invention includes a DC motor M to be calibrated, a transformer T and a measuring instrument I; the measuring instrument I is used to measure current and / or voltage; the excitation coil of the DC motor M Terminals B1 and B2 are respectively connected to the output terminals of the transformer T; the armature winding terminals S1 and S2 of the DC motor M are respectively connected to the two ends of the measuring instrument I; when calibrating, release the DC motor Fasten the bolts of the brush holder, turn on the power supply of the voltage regulator, and slowly rotate to adjust the angle of the brush. When the brush is on the neutral line, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com