Electric vehicle power system with hollow rotor motor and double-gear speed reduction with differential speed

A hollow rotor and planetary deceleration technology, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of increased volume and mass of the motor, decreased efficiency of the motor, complicated installation of the motor and drive axle, etc., and achieves light weight and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

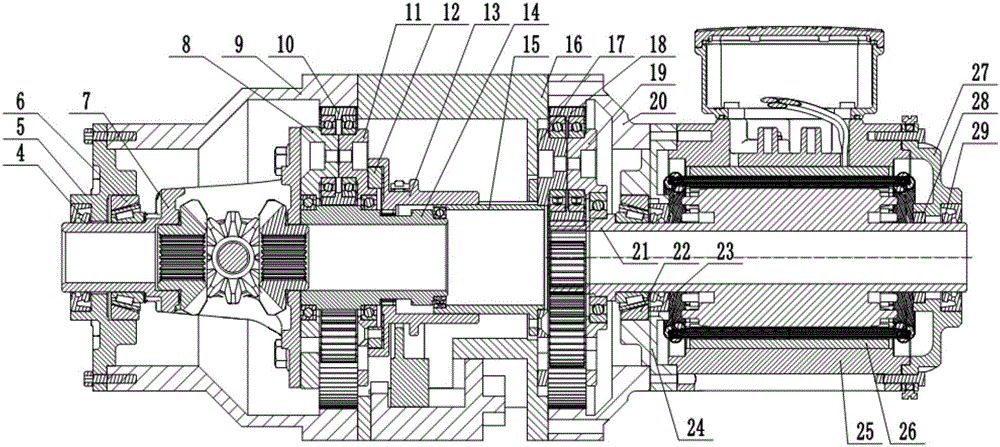

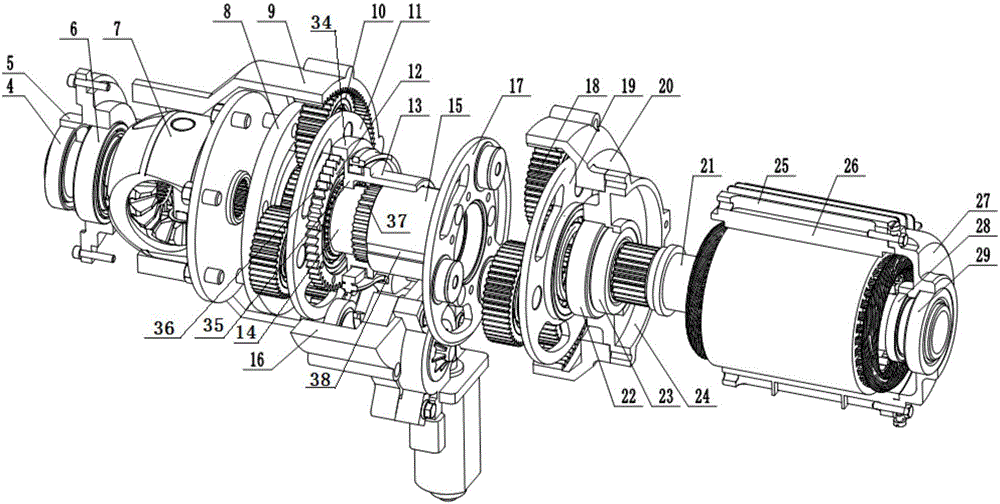

[0046] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0047] The power system of a hollow rotor motor and a double-gear planetary reduction belt differential electric vehicle of the present invention realizes the dual-gear deceleration of the motor under different working conditions through the two-stage deceleration and the hollow rotor brushless DC motor. High-efficiency output, while optimizing the motor structure, high transmission efficiency, compact structure, light weight, and easy installation and layout.

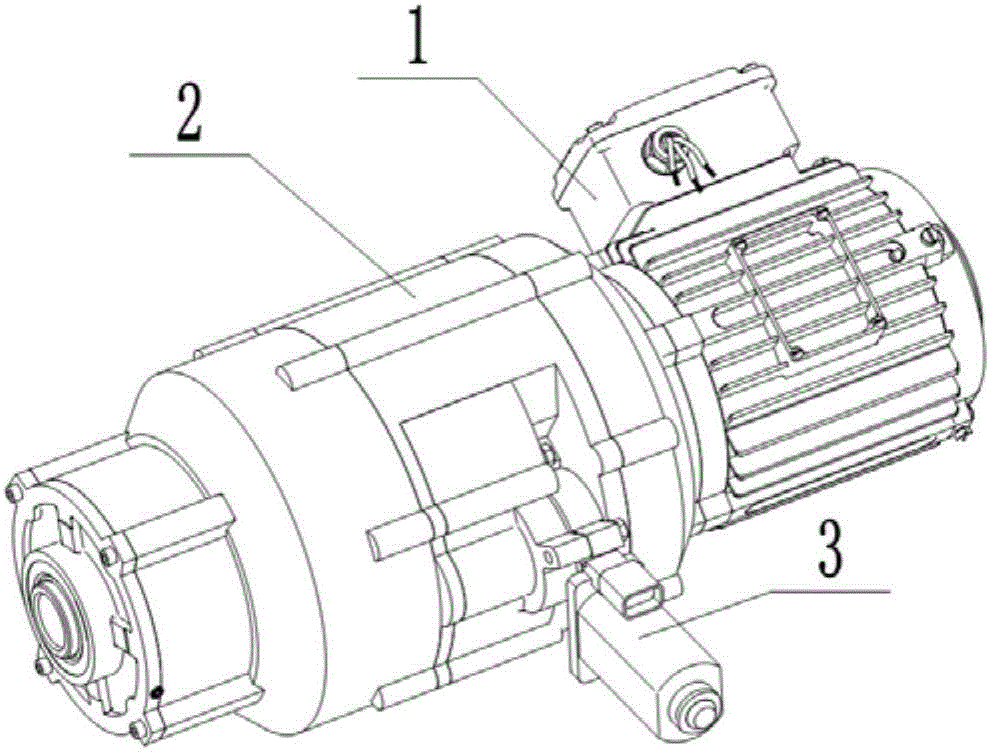

[0048] figure 1It is an overall schematic diagram of a hollow rotor motor and a dual-speed planetary reduction belt differential electric vehicle power system according to the present invention. Such as figure 1 As shown, the power system of the hollow rotor motor and the double-speed plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com