Simple trolley used for hoisting rolling line heat preservation roller and application method of simple trolley

A rolling line and trolley technology, which is applied in hoisting devices, portable lifting devices, etc., can solve the problems that the driving cannot directly hoist, disassemble, inconvenient installation, increase safety hazards, etc., so as to save maintenance manpower and equipment investment and use Flexible, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

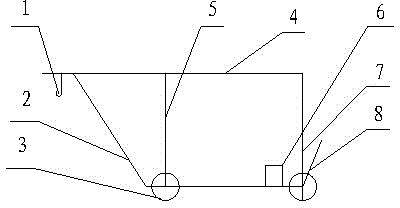

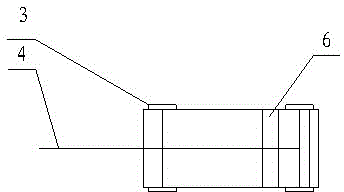

[0029] see now figure 1 and figure 2 , figure 1 It is a schematic structural diagram of a simple trolley for hoisting rolling line insulation rolls according to an embodiment of the present invention, figure 2 for figure 1 top view.

[0030] The simple trolley used for hoisting the thermal insulation roll of the rolling line of the present invention includes a frame, a hook and a counterweight, and is characterized in that: the frame is a rectangular frame made of steel pipes, and the four corners of the frame are provided with front and rear wheels 3 The 3rd support column 7 is vertically installed in the middle of the vehicle frame steel pipe between the two rear wheels, and the 2nd support column 5 is vertically installed in the vehicle frame steel tube middle between the two front wheels; the 3rd support column 7 and the 2nd support column 5 The same height, a beam 4 is welded and fixed between the 3rd support column 7 and the 2nd support column 5, the beam 4 is prov...

Embodiment 2

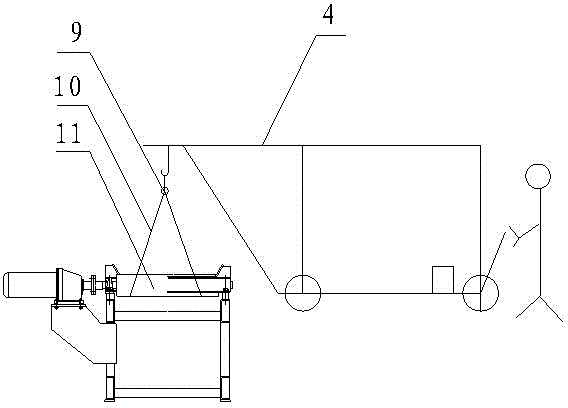

[0032] image 3 It is a schematic diagram of the use state of the trolley in the embodiment of the present invention.

[0033] The method for using the simple trolley for hoisting rolling line insulation rolls of the present invention is characterized in that it comprises the following steps:

[0034] a. Remove the bearing end covers at both ends of the insulation roller device, and remove the base bolts;

[0035] b. Push the prepared simple trolley to the designated position of the insulation roller; provide a chain hoist, and hang the chain hoist on the hook 1;

[0036] c. Cooperate the chain hoist with the wire rope to bolt and hang its insulation roller, and prepare for hoisting;

[0037] d. Use the chain hoist 9 to slowly raise the insulation roller to the specified height;

[0038] e. The maintenance personnel use the pusher 8 to push the trolley to the designated position and put down the insulation roller to complete the removal of the insulation roller.

[0039] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com