A method for increasing the phase transition temperature of cu2se-based thermoelectric materials

A technology of phase transition temperature and thermoelectric materials, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of degraded thermoelectric performance and instability, and achieve the effect of increasing phase transition temperature, fast speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

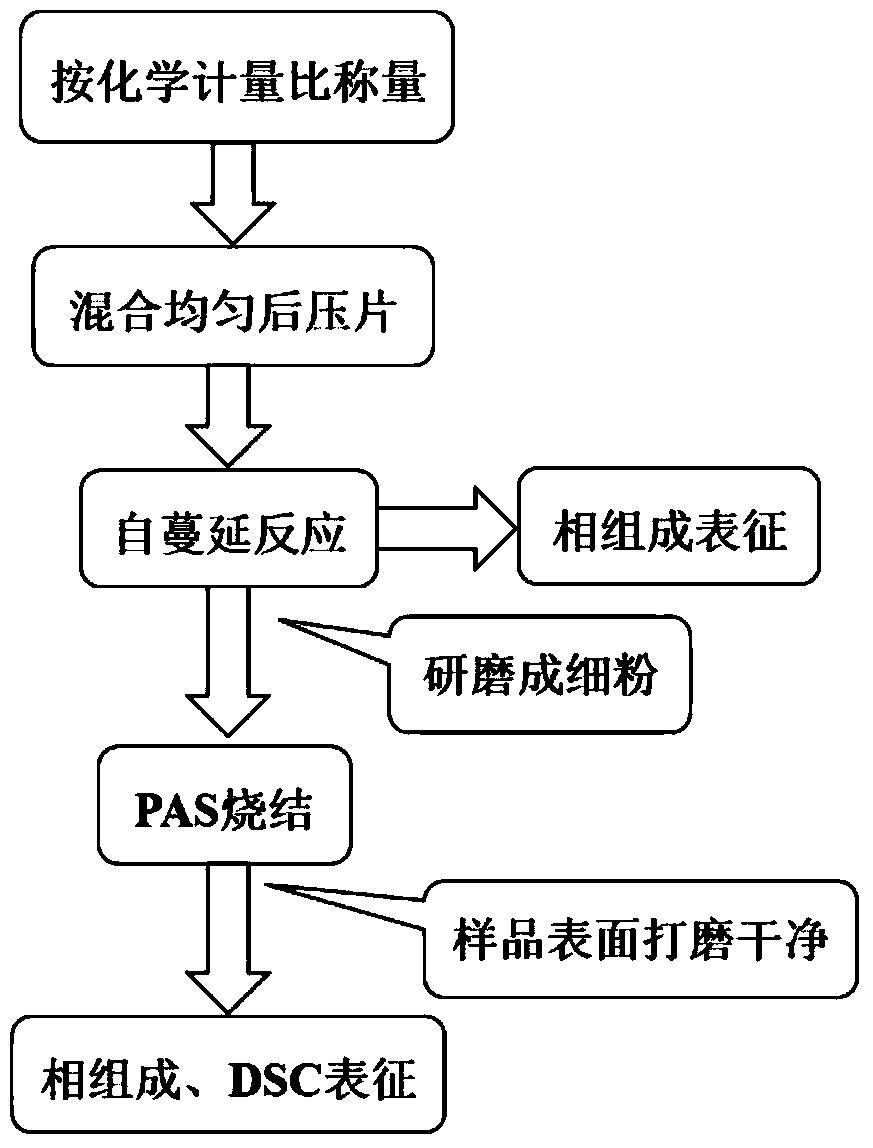

[0040] A way to improve Cu 2 Method for phase transition temperature of Se-based thermoelectric materials, Cu 2 The chemical composition of Se-based thermoelectric materials is Cd 0.004 Cu 1.996 Se, its technological process see figure 1 , which includes the following steps:

[0041] 1) Weigh the high-purity raw materials Cd powder, Cu powder and Se powder at a molar ratio of 0.004:1.996:1, slowly pour them into an agate mortar and mix them, and grind them manually for 10 minutes, then transfer the powders to diameters Carry out cold pressing in a 10mm steel mold, the cold pressure is 80MPa, and the holding time is 15min to obtain the column body raw material;

[0042]2) Remove the obtained cylinder raw material from the mold, place it in a quartz glass tube for vacuum sealing, and use argon gas to ventilate the quartz glass tube for 2 to 3 times before sealing. When sealing, the air pressure in the quartz glass tube is <100Pa. Finally, ignite the bottom of the quartz gla...

Embodiment 2

[0046] A way to improve Cu 2 Method for phase transition temperature of Se-based thermoelectric materials, Cu 2 The chemical composition of Se-based thermoelectric materials is Cd 0.008 Cu 1.992 Se, its technological process see figure 1 , including the following steps:

[0047] 1) Weigh the high-purity raw materials Cd powder, Cu powder and Se powder at a molar ratio of 0.008:1.992:1, slowly pour them into an agate mortar and mix them, and grind them manually for 12 minutes, then transfer the powders to diameters Carry out cold pressing in a 15mm steel mold, the cold pressure is 160MPa, and the holding time is 12min to obtain the column raw material;

[0048] 2) Remove the obtained cylinder raw material from the mold, place it in a quartz glass tube for vacuum sealing, and use argon gas to ventilate the quartz glass tube for 2 to 3 times before sealing. When sealing, the air pressure in the quartz glass tube is <100Pa. Finally, ignite the bottom of the quartz glass tube ...

Embodiment 3

[0052] A way to improve Cu 2 Method for phase transition temperature of Se-based thermoelectric materials, Cu 2 The chemical composition of Se-based thermoelectric materials is Cd 0.012 Cu 1.988 Se, its technological process see figure 1 , including the following steps:

[0053] 1) Weigh the high-purity raw materials Cd powder, Cu powder and Se powder at a molar ratio of 0.012:1.988:1, slowly pour them into an agate mortar and mix them, grind them manually for 15 minutes, and transfer the powders to diameters Carry out cold pressing in a steel mold of 16mm, the cold pressure is 240MPa, and the holding time is 10min to obtain the column raw material;

[0054] 2) Remove the obtained cylinder raw material from the mold, place it in a quartz glass tube for vacuum sealing, and use argon gas to ventilate the quartz glass tube for 2 to 3 times before sealing. When sealing, the air pressure in the quartz glass tube is <100Pa. Finally, ignite the bottom of the quartz glass tube di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com