Manufacturing apparatus of slag ball

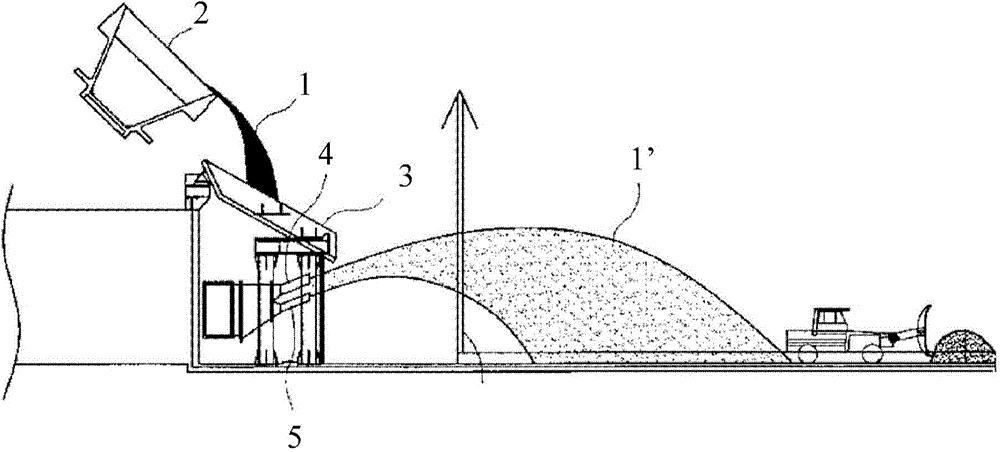

A technology for manufacturing devices and slag balls, applied in recycling technology and other directions, can solve the problems of wear resistance and strength decline, indoor temperature rise, and work site environment deterioration, etc., to improve strength and wear resistance, and reduce indoor temperature. , the effect of reducing the flying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. However, in describing the present invention, when the technical idea of the present invention is obscured or unclear by concretely describing a known structure, the description of the above-mentioned known structure will be omitted.

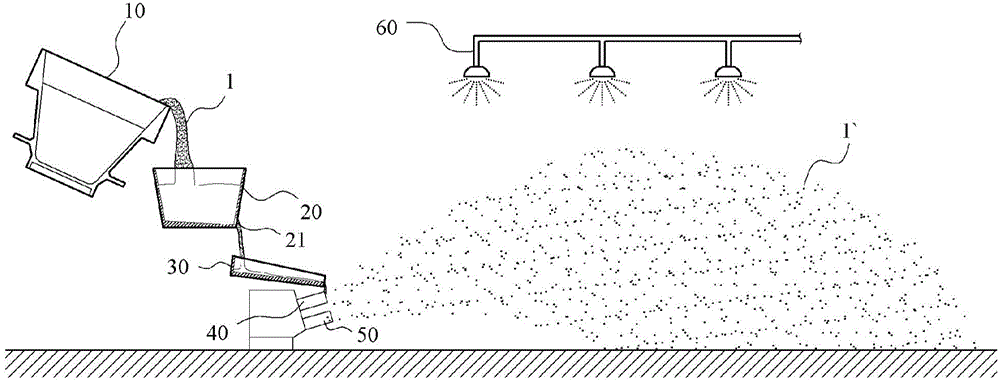

[0044] figure 2 It is a figure which shows the shot manufacturing apparatus of this invention.

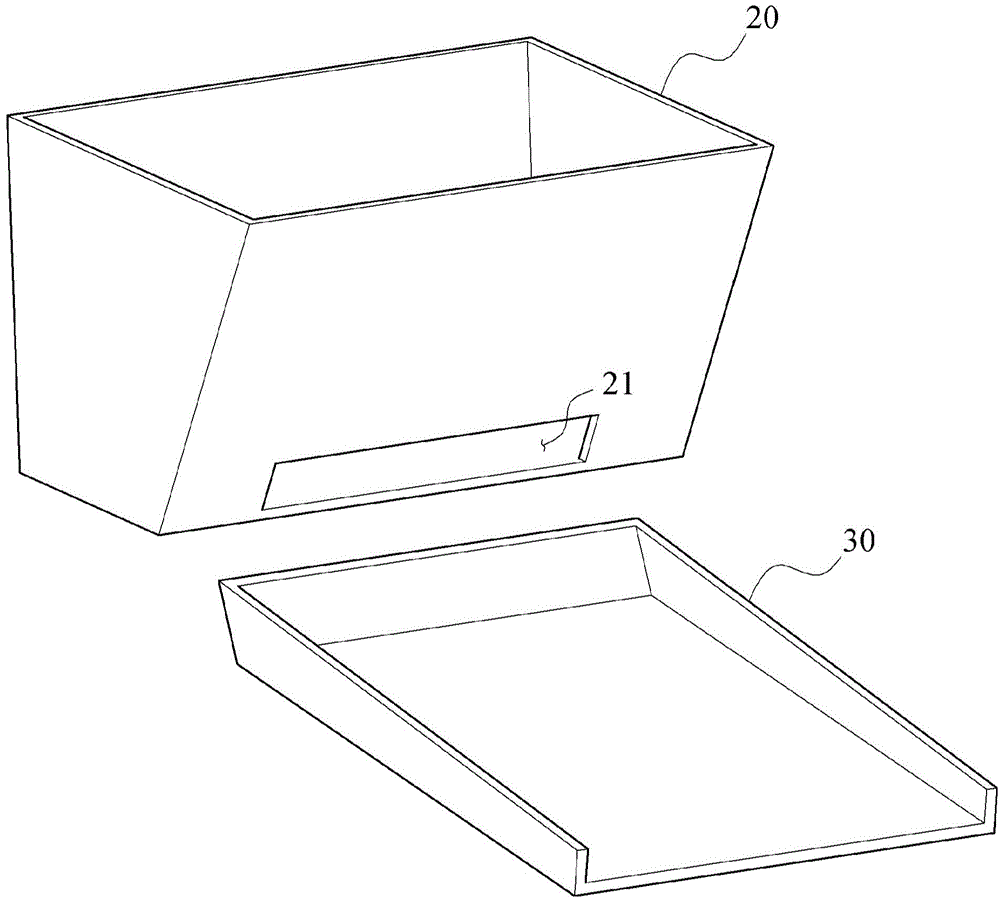

[0045] Such as figure 2 As shown, the slag ball manufacturing device of the present invention is characterized in that it includes: a slag tank 10 for discharging slag 1; A discharge hole 21 for discharging temporarily stored molten slag 1 is formed on the lower side of the front; a drain member 30 transfers the molten slag 1 discharged from the discharge hole 21 of the above-mentioned slag hopper 20; and a blower 40 is located at the end of the above-mentioned drain member 30 In the lower part of the slag 1 , the molten slag 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com