Hydraulic brake solenoid valve protector

A hydraulic brake and solenoid valve technology, applied in the direction of brake actuators, valve devices, valve details, etc., can solve problems such as insufficient coil suction, solenoid valve coil burnout, solenoid valve core reset, etc., to prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

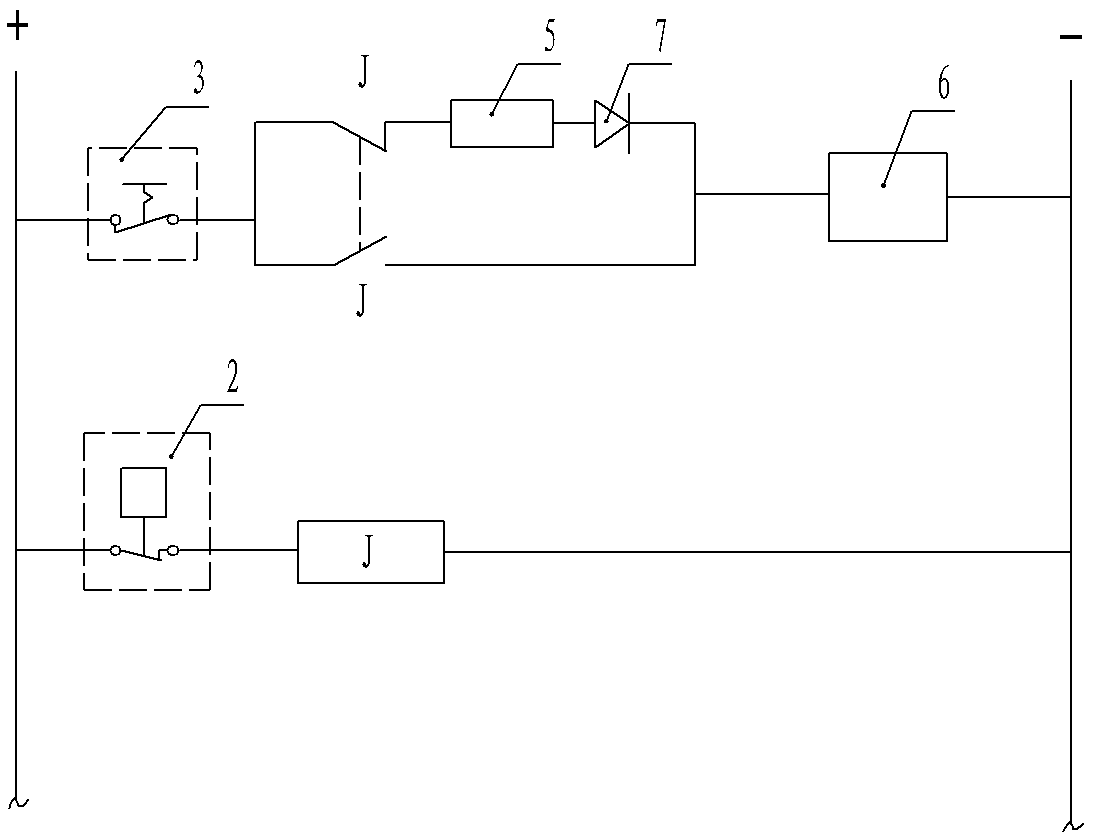

[0012] figure 1 The shown hydraulic brake solenoid valve protector includes a solenoid valve 6, and the coil of the solenoid valve 6 is connected to two power supply circuits through the parking brake switch 3 connected in series; one of the power supply circuits is connected in series with the dynamic disconnection contact of the relay J Point, current-limiting resistor 5 and light-emitting diode 7; another power supply circuit has a relay J moving contact in series; the relay J coil power supply circuit has a brake low-voltage switch 2 in series.

[0013] When the parking brake switch 3 is in the disconnected state and the solenoid valve 6 is in the de-energized state, the hydraulic brake takes effect at this moment, and the whole vehicle cannot walk and is in the parking brake state.

[0014] When the parking brake switch 3 is closed, the vehicle br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com