Sampling and pre-processing device capable of cleaning on line of diaphragm type liquid level meter

A pretreatment device and liquid level gauge technology, which is applied to the pipe group with cleaning holes, branch pipelines, pipes, etc., can solve the problem that the data cannot be truly reflected, various impurities and silt are easy to deposit, and the maintenance time is long, etc. problems, to achieve the effect of daily online cleaning, shorten cleaning time, and reduce measurement abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

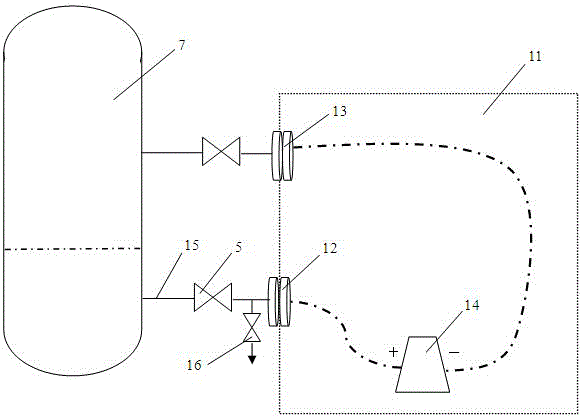

Image

Examples

Embodiment Construction

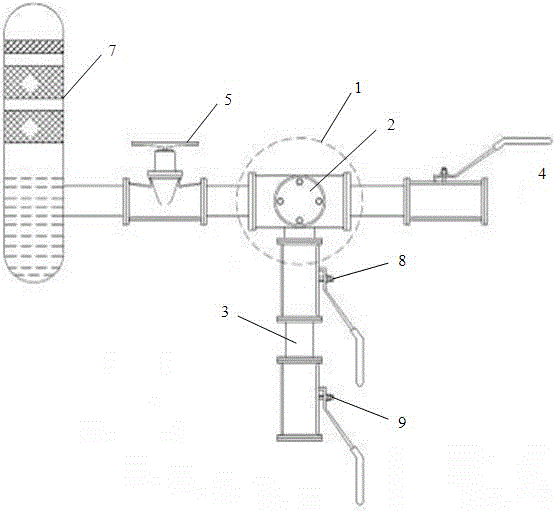

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

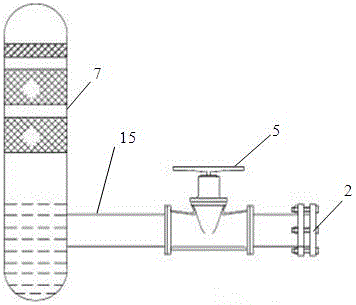

[0023] See image 3 , Figure 4 , An on-line cleaning diaphragm type liquid level gauge sampling pretreatment device 1, installed between the positive pressure side sampling valve 5 and the diaphragm type liquid level gauge positive pressure side diaphragm 2, mainly using the liquid to be constant in size The principle of directional transmission of pressure. The sampling pretreatment device 1 includes a cavity with five end faces. The top of the cavity is closed. The five end faces of the cavity are distributed as follows: the fifth end face 105 is the bottom face, the first end face 101, the second end face 102, and the first end face The three end surfaces 103 and the fourth end surface 104 sequentially enclose a circle. The first end surface 101, the second end surface 102, the third end surface 103, and the fifth end surface 105 are all provided with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com