High-temperature spectral selective absorption coating layer based on refractory metal boride and preparation method

A technology of metal borides and refractory metals, which is applied in the field of high-temperature spectral selective absorption coatings, can solve problems such as optical performance degradation and failure, and achieve excellent optical performance and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

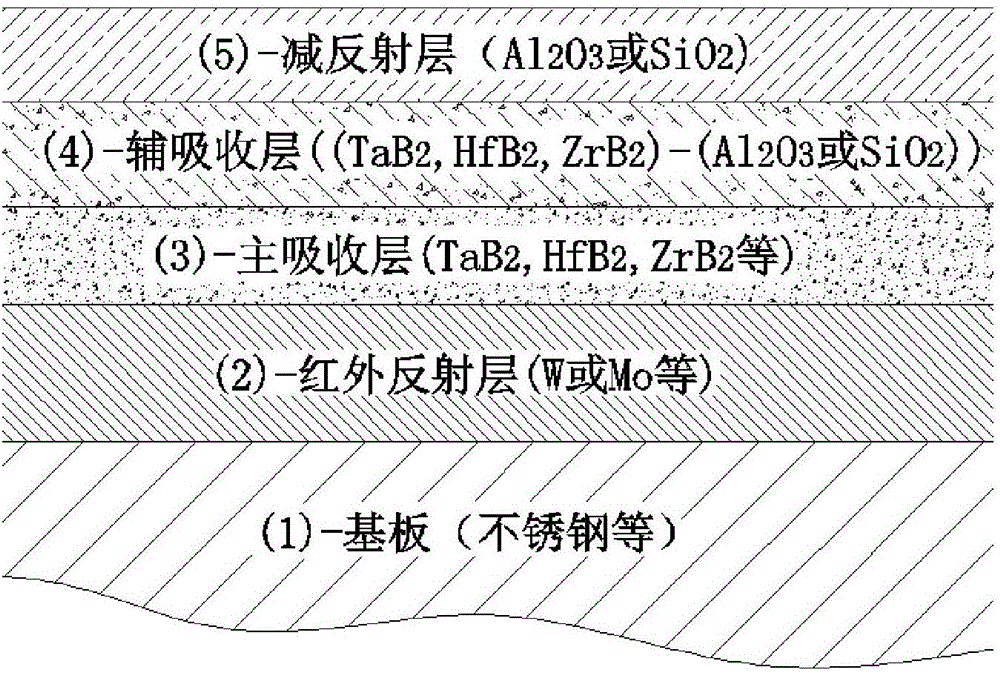

[0041] Example 1: see figure 1 , a high-temperature spectrally selective absorption coating based on refractory metal borides, an infrared reflective layer 2 is arranged on a substrate 1, and a spectrum main absorption layer 3, a spectrum auxiliary absorption layer 4 and Anti-reflection layer 5. The spectrum main absorption layer 3 is made of refractory metal boride HfB 2 One of the compositions, the film thickness is 20nm, the metal boride structure is amorphous or nanocrystalline, and it has the function of absorbing spectral energy and high temperature diffusion barrier.

[0042] The infrared reflective layer 2 is a high-melting-point metal thin film with a W content of 99.9-99.99% or a Mo content of 99.9-99.99%, and a film thickness of 100 nm.

[0043] The spectrum auxiliary absorption layer 4 is made of refractory metal boride TaB 2 A kind of dispersion in Al 2 o 3 or SiO 2 The composite layer is formed in the ceramic medium, the thickness of the composite layer can...

Embodiment 2

[0046] Example 2: see figure 1 , a high-temperature spectrally selective absorption coating based on refractory metal borides, an infrared reflective layer 2 is arranged on a substrate 1, and a spectrum main absorption layer 3, a spectrum auxiliary absorption layer 4 and Anti-reflection layer 5. The spectrum main absorption layer 3 is made of refractory metal boride TaB 2 or HfB 2 Two kinds of mixed composition, the thickness of the film is 50nm, the metal boride structure is amorphous or nanocrystalline, and it has the function of absorbing spectral energy and high temperature diffusion barrier.

[0047] The infrared reflective layer 2 is a high-melting-point metal film with a W content of 99.9-99.99% or a Mo content of 99.9-99.99%, and a film thickness of 300nm.

[0048] The spectrum auxiliary absorption layer 4 is made of refractory metal boride TaB 2 or H f B two mixed evenly dispersed in Al 2 o 3 or SiO 2 The composite layer is formed in the ceramic medium, the th...

Embodiment 3

[0051] Embodiment 3: see figure 1 , a high-temperature spectrally selective absorption coating based on refractory metal borides, an infrared reflective layer 2 is arranged on a substrate 1, and a spectrum main absorption layer 3, a spectrum auxiliary absorption layer 4 and Anti-reflection layer 5.

[0052] The spectrum main absorption layer 3 is made of refractory metal boride TaB 2 or HfB 2 The two mixtures are uniformly dispersed in Al 2 o 3 or SiO 2 The composite layer is formed in the ceramic medium, the thickness of the composite layer can be 80nm, and the refractory metal boride in the composite layer is in Al 2 o 3 or SiO 2 The volume percentage in the ceramic medium is 0.75, and the refractory metal boride is in an amorphous state or a nanocrystalline state, which mainly plays the role of absorbing spectral energy.

[0053] The infrared reflective layer 2 is a high-melting point metal film with a W content of 99.9-99.99% or a Mo content of 99.9-99.99%, and a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com