Refrigerating system and heat exchanger thereof

A refrigeration system and condenser technology, applied in the field of refrigeration systems and their heat exchangers, can solve the problems of increased production process difficulty, increased economic and time costs, etc., and achieve the goals of easy implementation, increased economic and time costs, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

[0034] One of the embodiments of the refrigerating system (such as "air conditioning system") of the present invention starts from the outlet header of the micro-channel condenser, that is, distributes the refrigerant entering the micro-channel evaporator from the single-phase liquid refrigerant, thereby realizing Better distribution of refrigerant in the evaporator improves system performance and reduces costs.

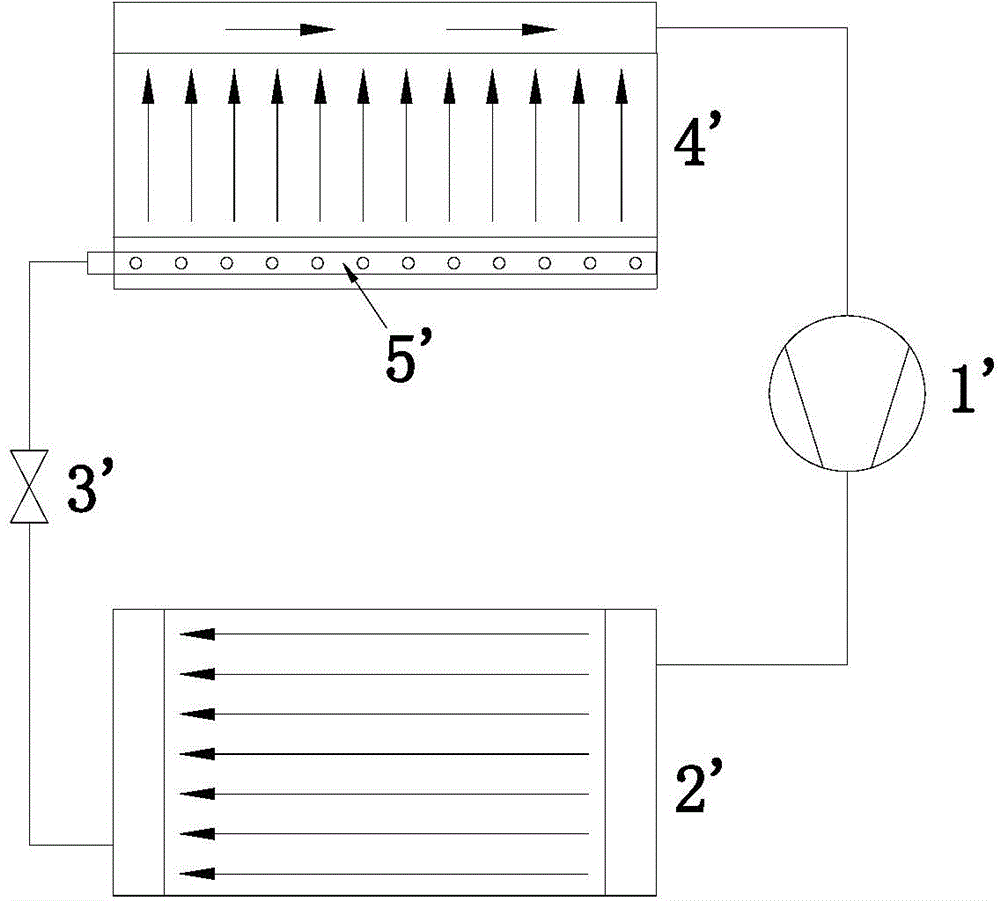

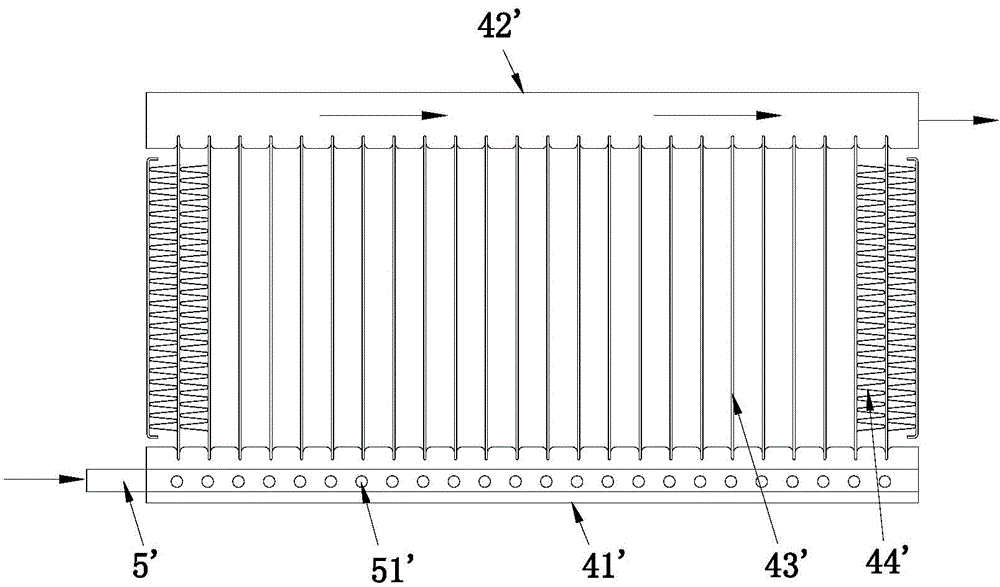

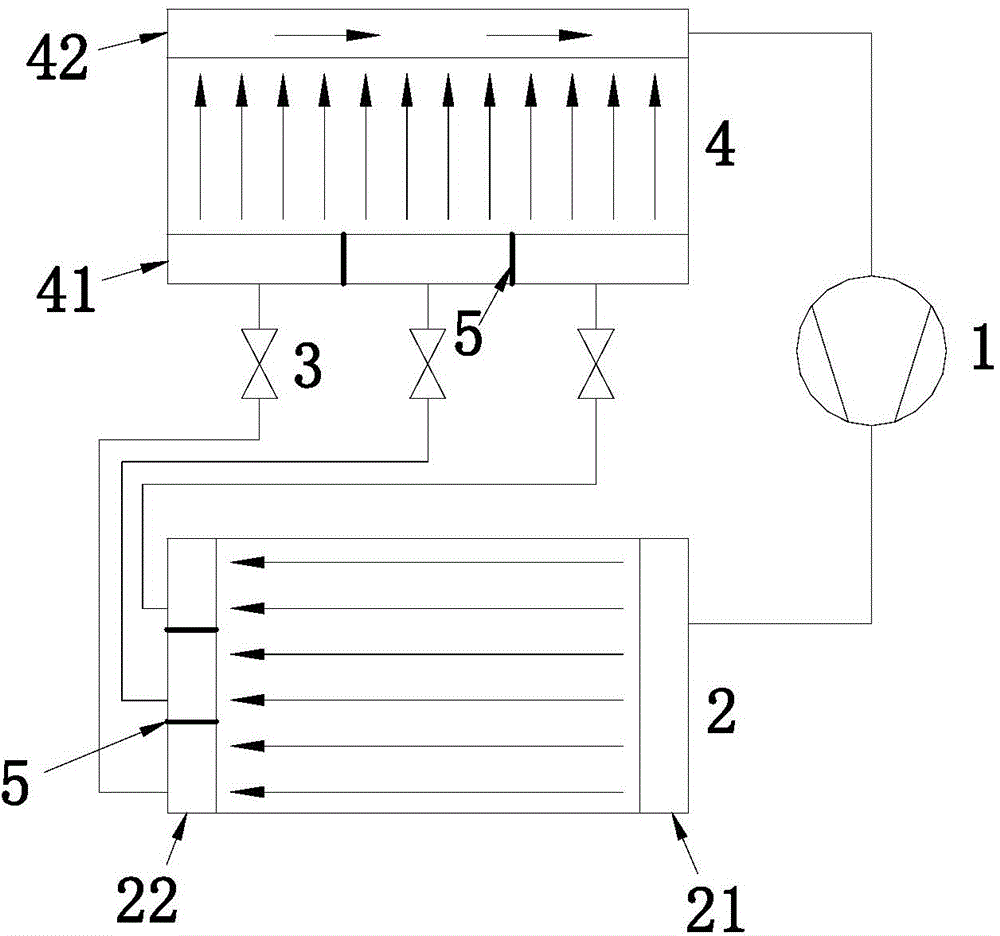

[0035] image 3 It is a schematic diagram of the principle of this embodiment. like Figure 3-Figure 6 As shown, the system includes a compressor 1 , a microchannel condenser 2 , a throttling device 3 and a microchannel evaporator 4 . On the outlet header 22 of the microchannel condenser 2 and the inlet header 41 of the microchannel evaporator 4, one or more n (n≥1) partitions 5 are correspondingly arranged, and the partitions 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com