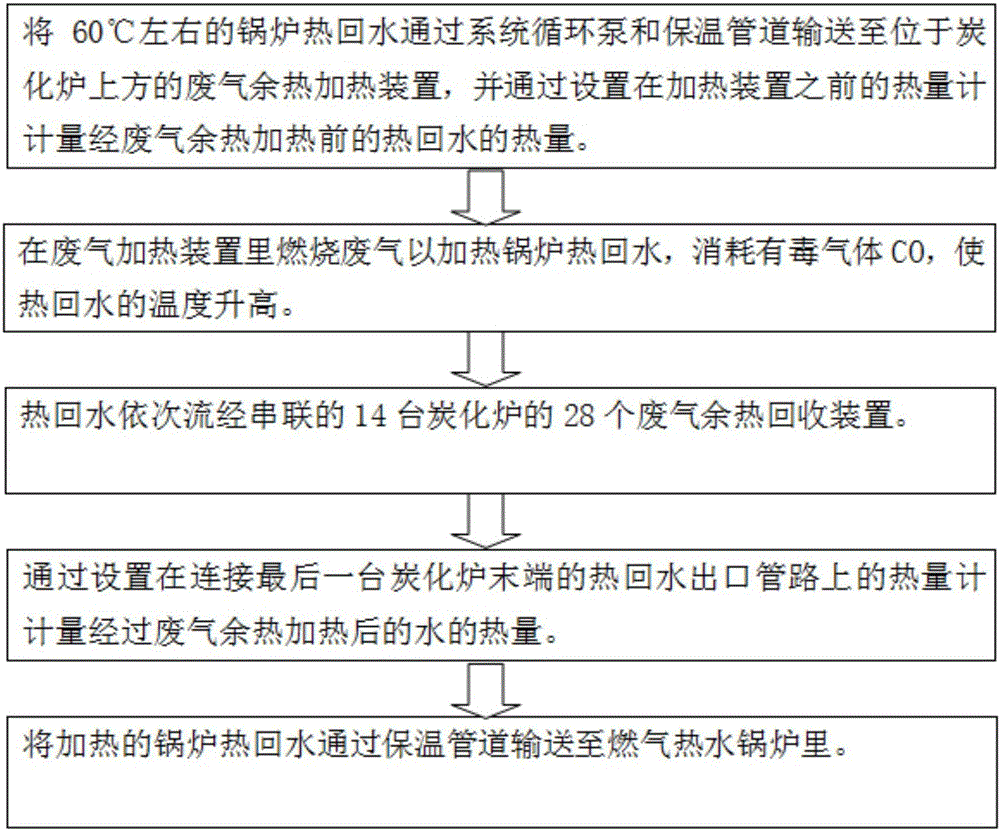

Horizontal type carbon tube furnace exhaust gas residual heat recovery system and using method thereof

A technology of waste heat recovery system and carbon tube furnace, which is applied in the direction of waste heat treatment, furnace, furnace components, etc., can solve the problems of heat pollution in the production workshop, waste of combustible gas, etc., to ensure effective recycling, save gas costs, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

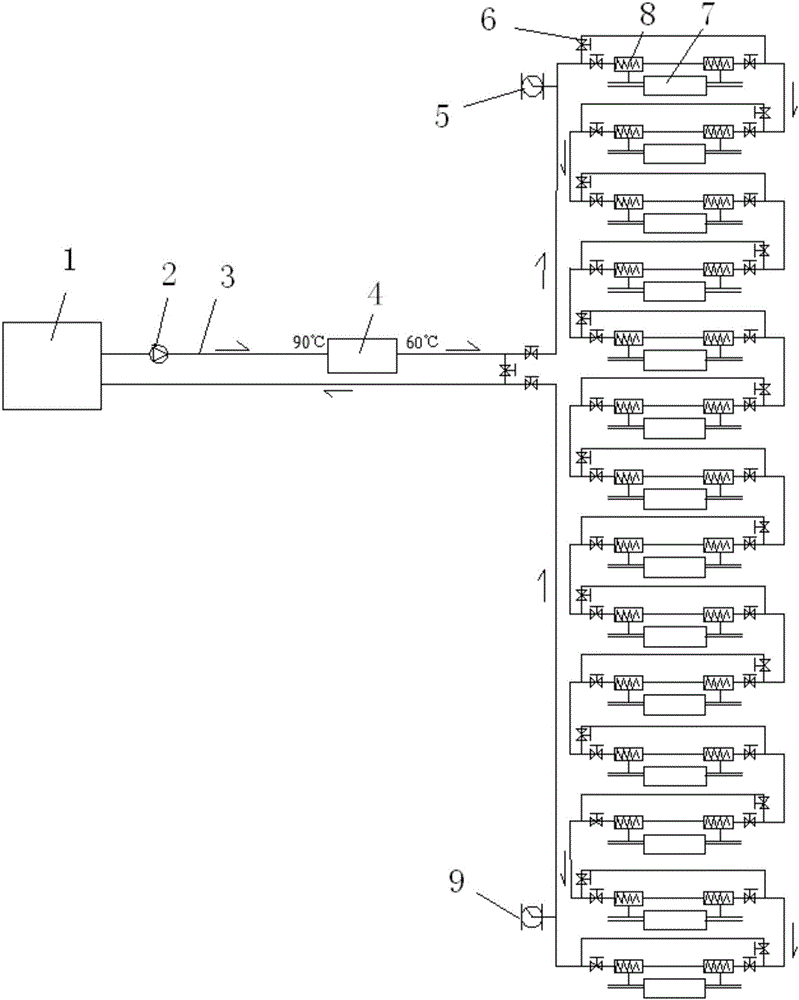

[0031] see figure 1 and figure 2 , 1.05MW gas hot water boiler 1 produces hot water 50m per hour 3 , transported to the hot area 4 through the circulating water pump 2 with a lift of 32m and the hot return water insulation pipe 3 of DN125. At this time, the temperature of the boiler outlet water at about 86°C-92°C drops to 60 after heat exchange in the hot area 4 ℃ or so.

[0032] Before the present invention was adopted, the hot water at about 60°C from the hot zone 4 directly flowed back to the gas-fired hot water boiler 1 for reheating and circulating flow, so that the exhaust gas of the horizontal carbon tube furnace 7 would be burned in vain in the workshop loss, resulting in heat loss and heat pollution in the workshop. After adopting the present invention, as figure 1 As shown, the hot water at about 60°C from the hot zone 4 is sent to the 2×14=28 waste gas waste heat heating devices 8 installed on the 14 gas-fired hot water boilers 1 in the workshop through the DN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com