Bagged liquid packaging processing detection device

A detection equipment and liquid technology, applied in the field of bagged liquid packaging processing and detection equipment, can solve problems such as difficulty in checking the air tightness of the package, and achieve the effects of high inspection efficiency, good effect and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

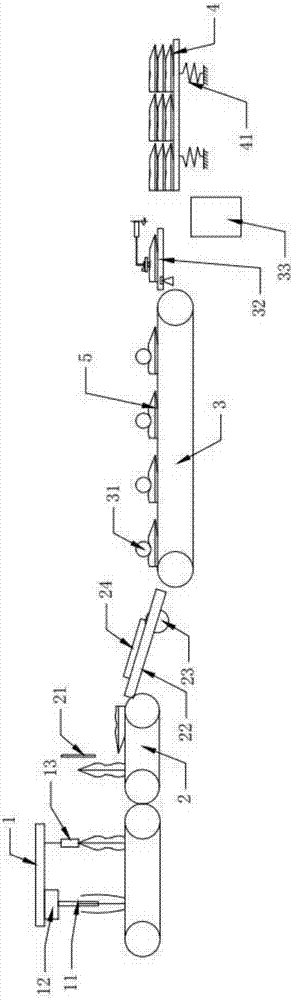

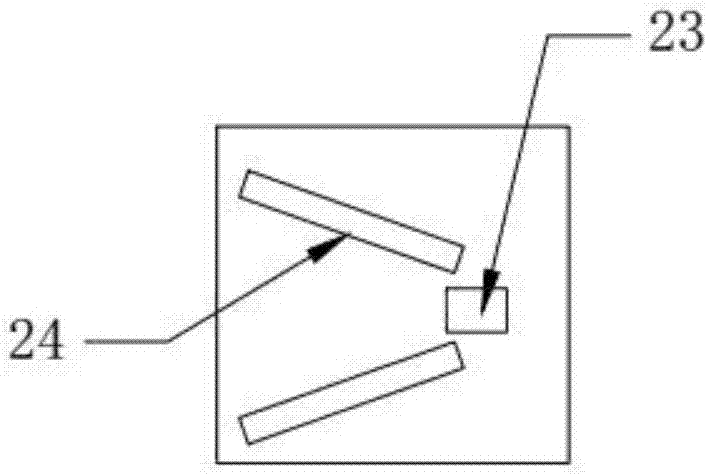

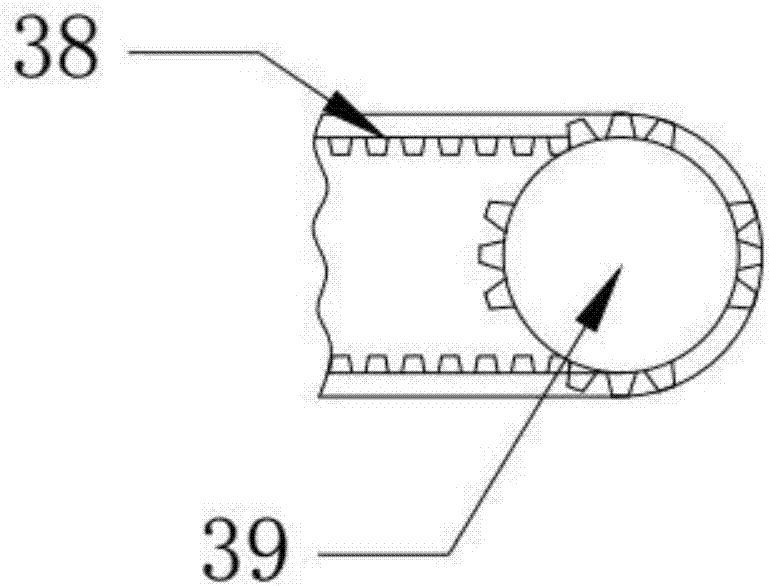

[0025] Embodiment 1, design a kind of bagged liquid packaging processing detection equipment, such as Figures 1 to 4 , including the filling device, the quality inspection device and the packaging device in sequence according to the progress of the assembly line; The material pipe 11 is connected with a discharge control meter; a feeding device for pushing down the material bag during the feeding process is provided between the filling device and the quality inspection device, and a feeding platform is provided between the feeding device and the quality inspection device, and the quality inspection device includes a quality inspection device. Conveyor belt 3, set a certain number of pressure rollers 31 above the quality inspection conveyor belt 3 at a certain distance, a gravity sensing platform 32 is provided at the exit of the quality inspection conveyor belt 3, and a gravimeter 36 is provided at the bottom of the gravity sensing platform 32; the packaging device includes pa...

Embodiment 2

[0033] Embodiment 2, the principle of this embodiment is the same as that of Embodiment 1, the difference is that the driving mechanism is a fixed crank-rocker mechanism driven by a motor, which drives the rocker to swing back and forth, and the rocker is connected to the feeding platform.

Embodiment 3

[0034] Embodiment 3, the principle of this embodiment is the same as that of Embodiment 1, the difference is that it can also be completed by differential speed, that is, two motors are respectively set up for forward and reverse rotation, and the rotation speeds are different, and the packaging bag is initially shaken during the shaking process. Quality inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com