Removing device for ringed waste residue in rotary kiln

A technology of cleaning device and rotary kiln, which is applied to descaling devices, furnaces, lighting and heating equipment, etc. It can solve the problems that the scraper cannot be adjusted according to the amount of slag cleaning, the mechanical arm tube is burned out, and the volume is large. It is not easy to achieve. Bending deformation, avoid burnout, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in specific embodiments with reference to the accompanying drawings. It should be noted that the following embodiments are only illustrative of the present invention by way of example, but the scope of protection of the present invention is not limited to this. The equivalent substitutions made by those skilled in the art to the present invention with the spirit of the present invention fall within the protection scope of the present invention.

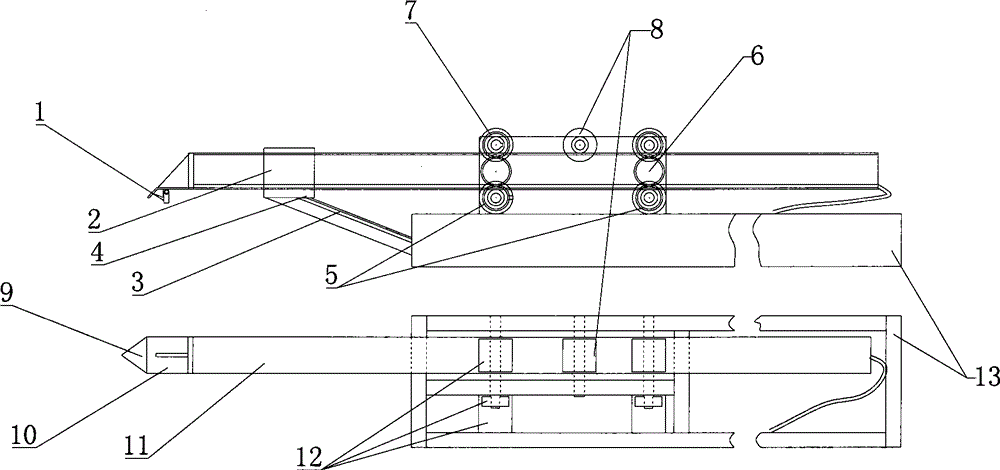

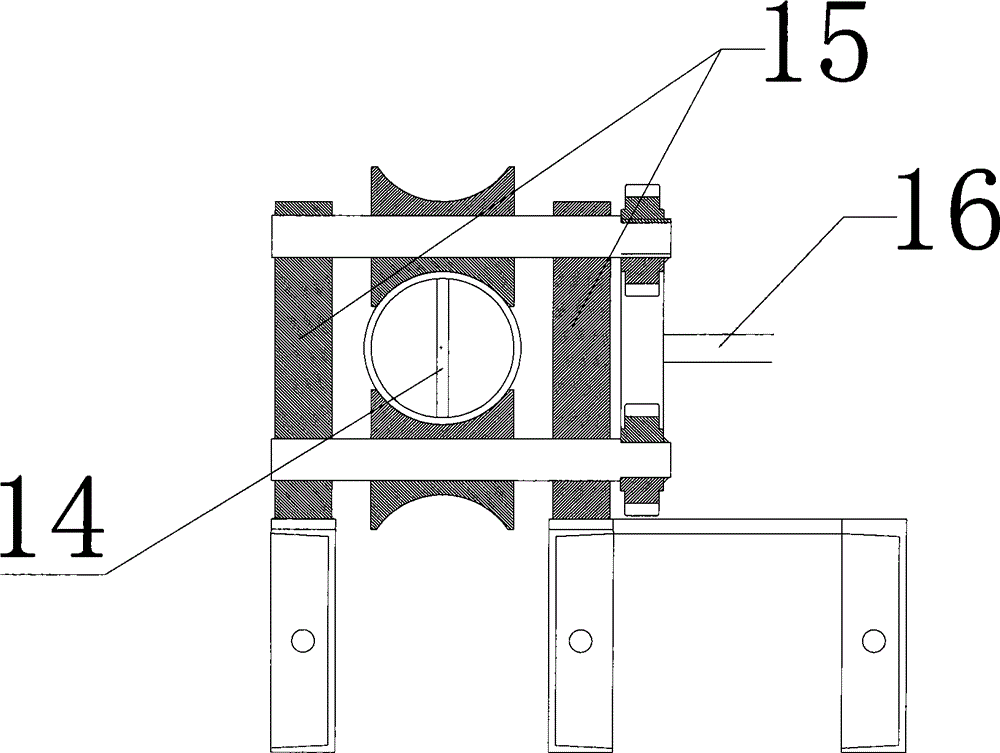

[0014] A device for removing ring formation in rotary kiln, such as figure 1 As shown, the bracket 4, the body 13, the blade 9, the tube surface cooling device 2, the supporting wheel 5, the pressing wheel 7, and the mechanical arm 11 are included. The tube surface cooling device 2 is fixed to the robot arm 11 through a bracket 4. The pressing wheel 7 and the supporting wheel 5 press the mechanical arm tightly to ensure the balance of the mechanical arm. The reducer 16 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com