Novel integrated alternating current servo techogenerator set

An AC servo and integrated technology, applied in the direction of devices using electric/magnetic methods, can solve the problems of high manufacturing cost, asymmetric magnetic circuit, uneven air gap, etc., and achieve small linear error, stable operation, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of a novel integrated AC servo speed measuring unit of the present invention will be further described below in conjunction with the accompanying drawings.

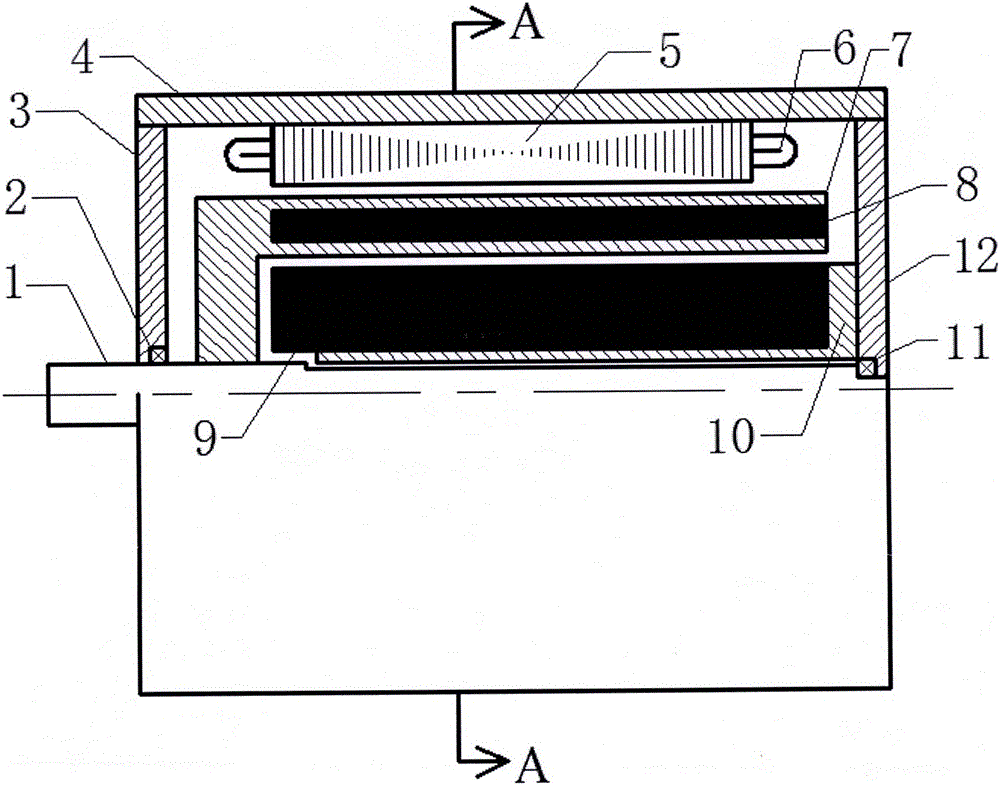

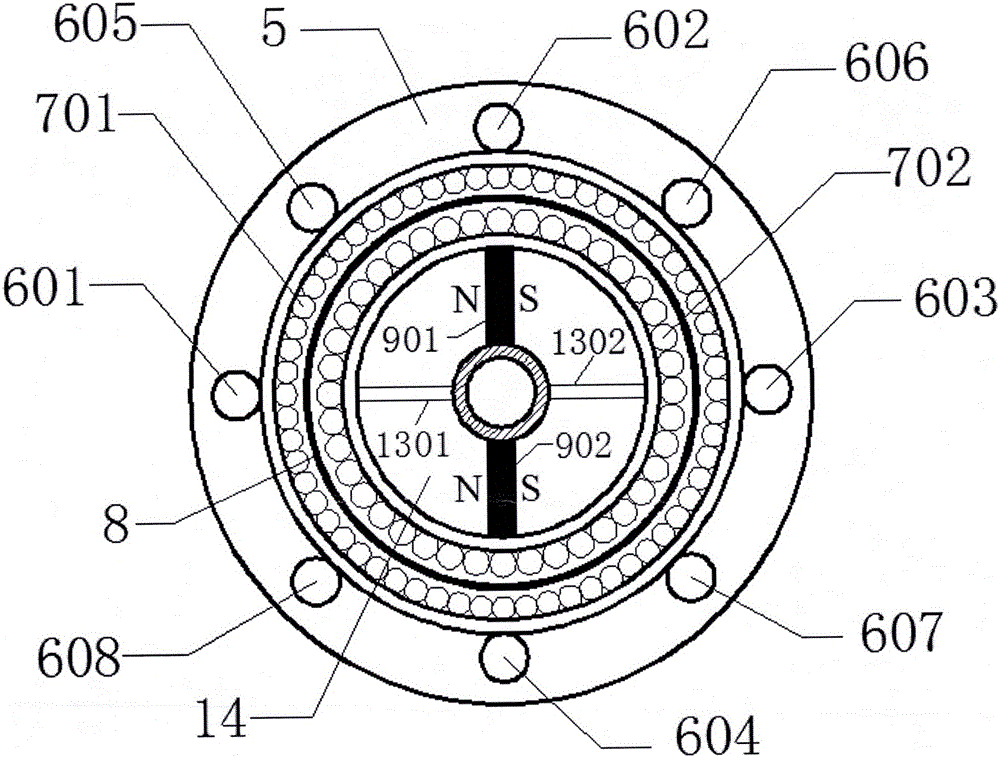

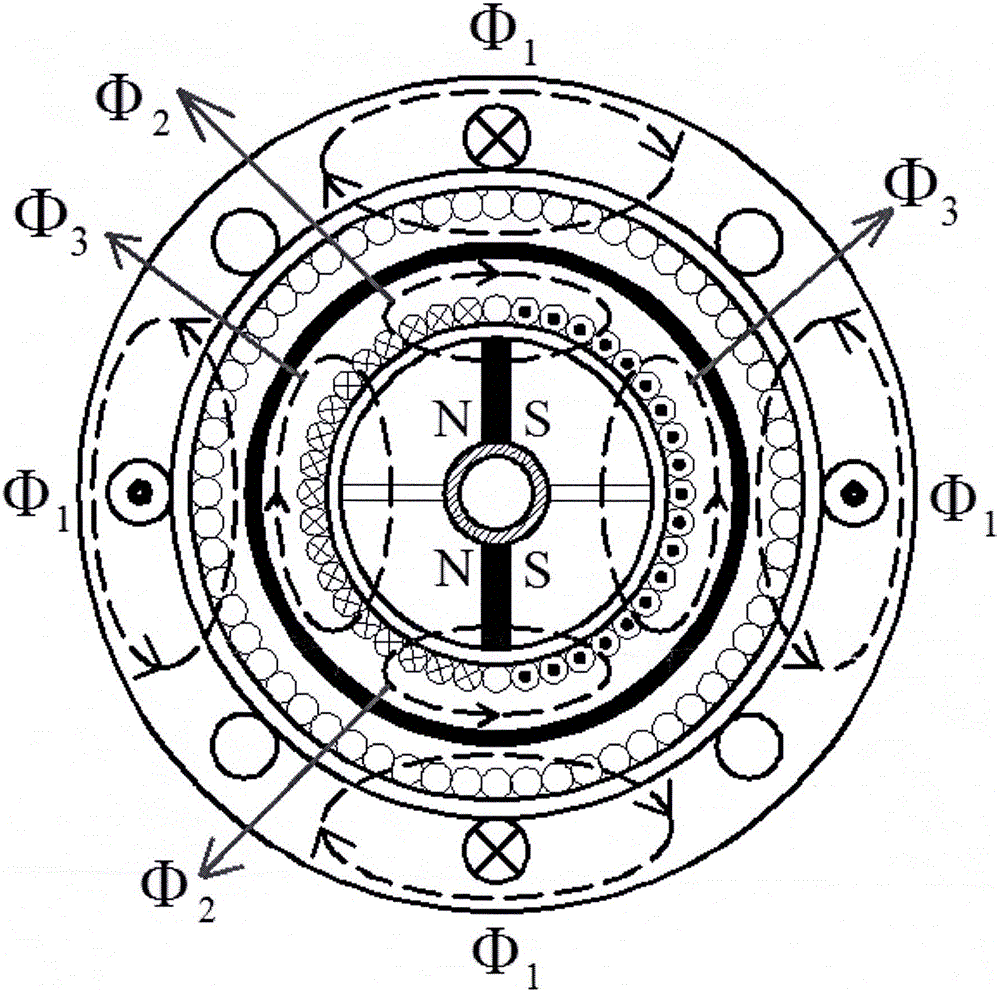

[0027] Such as figure 1 , figure 2 As shown, a new type of integrated AC servo speed measuring unit includes a rotating shaft 1, a front end cover bearing 2, a front end cover 3, a casing 4, an outer stator core 5, an excitation winding 6, a slotless rotor 7, a magnetic isolation pillowcase 8, a permanent Magnetic steel 9, copper sleeve 10, rear end cover bearing 11, rear end cover 12, Hall element 13 and inner stator core 14;

[0028] The rotating shaft 1 passes through the front end cover bearing 2, the slotless rotor 7, the center hole of the copper sleeve 10 and the rear end cover bearing 11 in sequence, and is fixed to the casing 4 through the front end cover 3 and the rear end cover 12 respectively;

[0029] The copper sleeve 10 is fixed on the inner side of the rear end cover 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com